Managing quality control for imported cloth masks has always been a challenge—especially when orders span thousands of units and multiple styles. From overlooked stitching errors to missing packaging components, traditional QC methods often lack traceability and real-time visibility. That’s where QR code tracking changes everything.

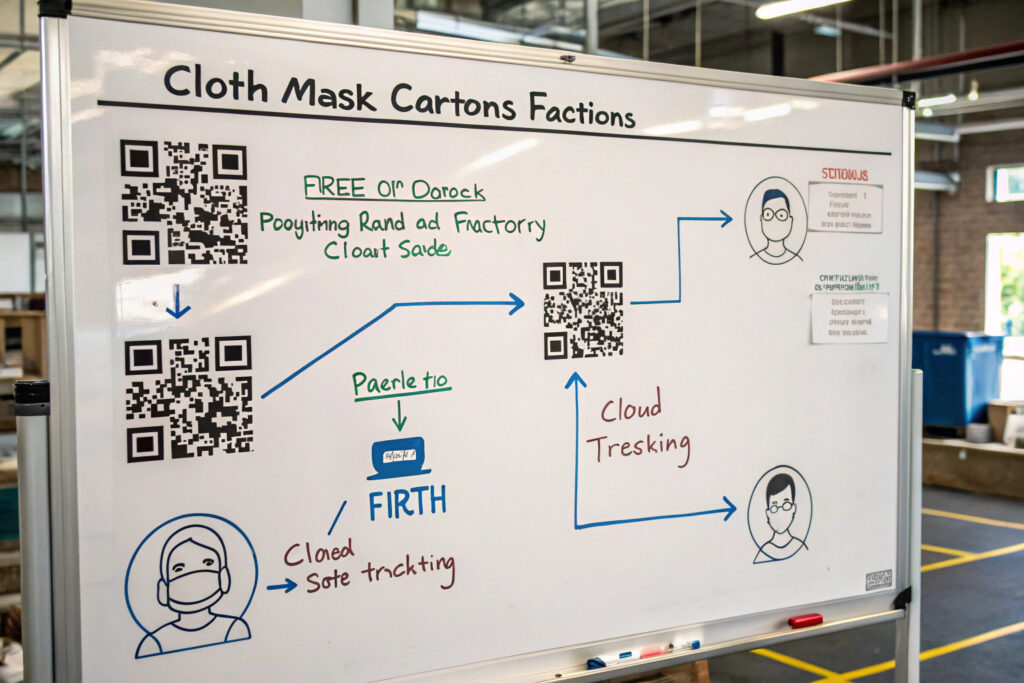

QR code tracking adds a digital identity to every cloth mask shipment, enabling real-time quality verification, production traceability, and transparent data-sharing between suppliers and buyers. With a simple scan, buyers can confirm lot performance, test results, and factory accountability.

In this article, I’ll explain how QR codes can streamline quality assurance from the production line to the destination warehouse—while reducing disputes, delays, and defects.

What Is QR Code Tracking in Cloth Mask Production?

How Does QR Tracking Work in the Mask Supply Chain?

QR code tracking assigns each batch or carton of cloth masks a unique digital ID. That code links to a database containing:

- Production date

- Material composition

- QC inspection status

- Test reports (e.g., shrinkage, colorfastness, antimicrobial)

- Factory location and supervisor team

When our team at Global-Caps packs a batch, we affix a printed QR label on each carton. The buyer or their agent can scan the code using a phone or tablet and instantly access this info online.

Platforms like GS1 and Zebra Technologies offer enterprise QR tracking integration.

How Is This Different from Traditional Labeling?

Traditional cartons carry a batch number and SKU. But if an issue arises—say, with a particular mask print or ear loop—it’s hard to trace without opening boxes or emailing spreadsheets.

With QR codes, every stakeholder in the chain—from factory floor to customs to warehouse—gets the same real-time data view. That drastically cuts communication time and increases accountability.

How Can QR Tracking Improve Quality Control Processes?

Does It Help Catch Errors Earlier?

Yes. By integrating QR tracking into our QC checkpoints, we flag issues instantly. For example:

- Stitch misalignment? Mark the batch in the dashboard.

- Wrong packaging insert? Upload the error photo to the batch folder.

- Failed antimicrobial test? Auto-alert the client or stop shipping.

Each scan event logs who checked what and when. This helps our buyers like Ron confirm if a defect was caught before shipment—or where it occurred in the process.

We use tools like Zoho Inventory and QR Tiger for cloud-linked tracking.

Can Buyers Participate in QC Remotely?

Yes. Some of our buyers have us share the QR dashboard via link, allowing their QA team to:

- Approve batches before shipment

- Leave feedback on sample photos

- Request retesting for flagged lots

- Download real-time inspection logs

This adds transparency, especially for clients using 3rd-party QC agents like QIMA or Asia Inspection.

How Does QR Tracking Support Compliance and Testing?

Can You Link Test Reports to Each Batch?

Exactly. Every QR label in our system links to:

- Fabric supplier data

- ISO or AATCC lab test reports (PDF)

- Production compliance (e.g., OEKO-TEX, BSCI)

- Antimicrobial or filter layer certifications

For example, if a shipment includes masks with Silvadur™ antimicrobial finish, the buyer can scan the code and retrieve the MSDS, batch test result, and declaration letter.

We also store washing durability test results so buyers know how long coatings remain effective.

You can check more on AATCC testing or OEKO-TEX verification.

How Does It Help With Customs or Disputes?

QR records act as a tamper-proof audit trail. If customs requests material declarations or if a dispute arises (wrong model, missing units), buyers and authorities can:

- Match the code to official packing lists

- Verify material origin and treatment declarations

- Confirm photos and timestamps of final packed goods

This is especially useful for complex orders that include kids’ masks, antimicrobial designs, or PPE-grade filtration.

How Can QR Tracking Enhance Post-Shipment Traceability?

Can Importers Track Individual Cartons?

Yes. We generate a QR code for each master carton, allowing importers or 3PLs to scan upon delivery. This connects inbound logs with outbound fulfillment.

Retailers or warehouses can use the QR system to:

- Confirm quantity per carton

- Identify mix-ups by SKU or style

- Store photos of carton condition at arrival

- Link to Amazon FBA or Shopify inventory

Our API integrates with systems like ShipBob or Flexport for seamless inbound tracking.

Can It Help With Product Recalls or Returns?

Absolutely. If a buyer detects an issue after delivery (e.g., label misprint, ear loop breaks), they can use the QR code to trace:

- Which production lot was affected

- How many units are involved

- Which regions received those cartons

This precision speeds up any recall, replacement, or credit issuance, reducing losses and protecting brand integrity.

Conclusion

QR code tracking is more than just a scanning tool—it’s your virtual QC assistant. From live batch verification and inspection history to test reports and recall readiness, this technology transforms quality control into a smart, data-driven process.

At Global-Caps, we embed QR tracking into every fabric mask shipment to help buyers like Ron reduce uncertainty, enforce accountability, and build trust across borders.

Let QR tracking be the bridge between your quality standards and the factory floor—ensuring every mask meets your expectations.