When Ron, one of our long-term clients from the U.S., asked if his pleated mask design could pass European and American testing standards, I knew this was a common concern for many of our international partners. It's not enough to create a stylish or breathable mask. When targeting large markets like the U.S., EU, and Japan, passing regulatory and safety standards is non-negotiable.

Yes, your pleated mask design can meet international standards—but only with rigorous planning, certified materials, and a partner who understands global compliance.

We’ve helped hundreds of clients, from boutique sellers to Walmart-scale importers, bring their mask ideas to life and still pass EN 14683, ASTM F3502, and GB 2626 testing. It all starts from the design table and ends at the customs gate—with quality checkpoints at every step.

What Are the Global Compliance Standards for Pleated Masks?

What Tests Are Required for ASTM and EN Certifications?

Certifications like ASTM F2100 and EN 14683 are the gold standard for medical and general-use pleated fabric masks. To qualify, a mask must pass tests for bacterial filtration efficiency (BFE), particulate filtration (PFE), differential pressure (Delta P), flammability, and fluid resistance.

ASTM F2100, for example, has three levels—each demanding higher protection. Level 1 is ideal for low-risk environments, while Level 3 is used for surgery. The EU standard, EN 14683, uses Types I, II, and IIR.

You can reference full ASTM F2100 requirements here and EN 14683 details via BSI. Even for non-medical use, clients are increasingly asking for masks that align with these categories to meet institutional or retail compliance.

Do Pleated Fabric Masks Fall Under GB2626 in China?

No, unless the mask is marketed as a KN95 or respirator. GB2626 is China’s standard for particulate respirators, including KN95-style masks. However, many buyers request GB/T 32610-2016, which covers daily protective masks.

For pleated cloth masks intended for daily wear, especially in urban environments, this standard assesses filtration efficiency, sealing performance, and microbial limits. If you're exporting from China, you can read GB/T 32610 here in translation.

How to Select Materials That Pass Lab Testing?

Is Your Inner and Outer Layer Fabric Certified?

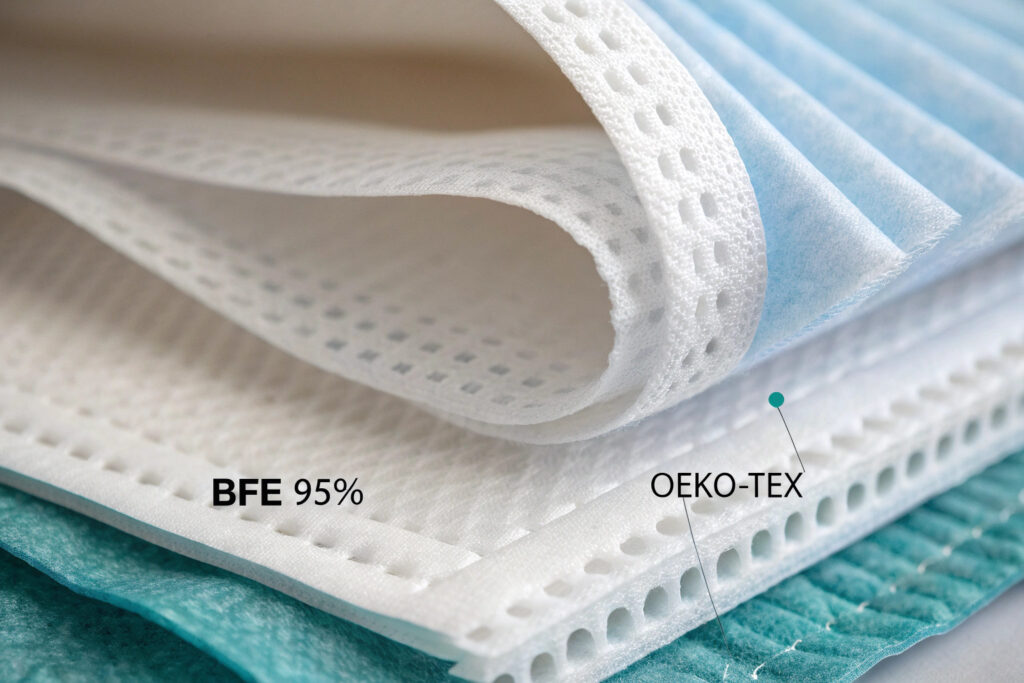

Many clients mistakenly assume any soft cotton or polyester will pass. But international standards require certified textiles—especially for inner layers touching the skin. Look for OEKO-TEX® or SGS skin-safety certifications.

Our masks often use 100% combed cotton or poly-cotton blends that have passed OEKO-TEX Standard 100. Outer layers are usually chosen for durability or print quality, like water-repellent polyester treated with C6 fluorocarbon or plant-based alternatives.

When sourcing fabrics, avoid off-market rolls. Make sure your supplier can provide test reports from labs like Intertek or TÜV SÜD.

What Is the Role of the Middle Filter Layer?

For better BFE or PFE scores, we often integrate a meltblown or spunbond filter layer in 3-ply pleated masks. Clients can choose removable or sewn-in options.

We source BFE95+ meltblown material backed by in-house testing and third-party validation. See examples of certified materials from Jiangsu Kanai Filter Material Co. or browse listings on Made-in-China with verified filter data.

Can Custom Designs Still Be Compliant?

Does Custom Printing Affect Breathability and Safety?

Yes, ink choice and print method impact compliance. Sublimation printing on polyester layers is breathable and colorfast, but if you over-layer ink, it blocks airflow and flunks the Delta P test.

If you're designing a mask with logo placement or graphics, we recommend reactive printing for cotton masks, and heat transfer or sublimation for polyester. Always test your finished product with the print included.

We had a client from Italy who initially used heavy pigment print on the outer layer. Their mask failed both breathability and colorfastness under ISO 105-C06. We helped them switch to lighter sublimation layers and passed on re-test.

How to Balance Design and Regulatory Tech Packs?

All custom designs need a technical pack that includes specs, fabric codes, layer structure, tolerances, and visual renderings. We provide a downloadable template and assist clients with generating EN and ASTM aligned documentation.

Our R&D team will simulate airflow testing, shrinkage, and wash-cycle performance in pre-production. You can learn about tech packs here and download editable templates on Techpacker.

How to Manage Testing, Certifications & Logistics?

Where Should You Test to Meet FDA, CE, or ASTM?

While in-house labs are useful, recognized buyers want third-party test reports. In our case, we partner with SGS, BV, and Eurofins to run standardized tests under ISO 10993 or EN 14683 protocols.

If your U.S. importer needs FDA compliance, we help register under 21 CFR 878.4040 for non-surgical masks. For Europe, we support CE self-declaration or Module B certification through Notified Bodies.

Always plan 2–3 weeks for full-cycle testing, especially if exporting to multiple markets.

What Export Documents Are Needed for Masks?

For the U.S. or EU, basic export documents include: packing list, invoice, Form A or RCEP certificates, and test reports. Some ports may request FDA listing or CE DoC. For Russia and CIS countries, EAC Certification is crucial.

We prepare customs-ready files, QR-coded cartons, and even provide GTIP codes under HS 630790. Check U.S. Customs HS guidance or WCO’s Harmonized System to avoid misclassification.

Conclusion

Meeting international standards for pleated fabric masks isn't just about material—it’s about smart design, precise documentation, and verified partners. From BFE testing to breathable ink to proper GTIP filing, every step matters. At Global-Caps, we integrate compliance into every order. So, whether you’re a first-time designer or a major distributor, we’ll help your mask stand up to every regulation, every time.