The integration of advanced functional textiles into personal protective equipment has evolved beyond basic protection to encompass sophisticated aesthetic and adaptive capabilities. Thermal camouflage textiles for mask aesthetics represent a cutting-edge fusion of materials science, optical engineering, and wearable technology, creating dynamic surfaces that can alter their thermal signature and visual appearance in response to environmental or physiological changes. For designers and manufacturers seeking to create next-generation masks with adaptive visual properties, understanding implementation strategies for these intelligent textiles is essential for developing products that are both technologically advanced and visually compelling.

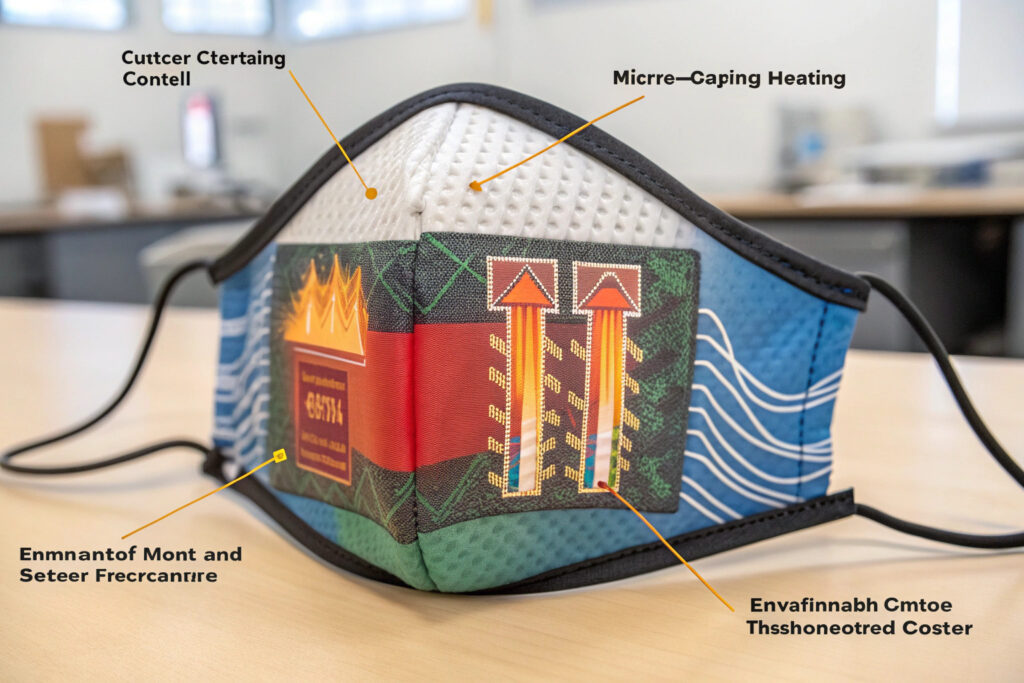

Thermal camouflage textiles for mask aesthetics are smart material systems that utilize thermochromic pigments, phase-change materials, and micro-thermal regulation to dynamically change color, pattern, or transparency based on temperature fluctuations, enabling masks to adapt their appearance to different environments, blend with skin tones, or express physiological states through visual changes. These technologies transform static mask designs into responsive, expressive interfaces that can enhance user engagement, provide subtle health indicators, or simply offer novel aesthetic experiences. Successful implementation requires careful consideration of material selection, activation mechanisms, durability, and user experience design.

The global market for smart textiles is projected to reach $11.6 billion by 2030, with color-changing applications experiencing significant growth. Research in Advanced Functional Materials demonstrates that properly engineered thermochromic systems can achieve full color transition cycles in under 30 seconds with stability through thousands of cycles. For mask applications ranging from fashion-forward consumer products to specialized occupational gear, thermal camouflage offers unique opportunities for personalization and functionality. Let's explore the practical implementation pathways for these transformative textile technologies.

What Thermochromic Material Systems Offer Optimal Performance?

The foundation of thermal camouflage lies in materials that change color with temperature. Different thermochromic systems offer varying color ranges, transition temperatures, and integration methods suitable for textile applications.

How Do Leuco Dye-Based Systems Work for Textile Integration?

Leuco dye thermochromic systems are the most commercially viable for textiles. They consist of three components: a color-forming dye (leuco dye), a color developer, and a solvent. When temperature rises above a specific threshold, the solvent melts, separating the dye from the developer and causing the color to disappear or change. These systems can be:

- Microencapsulated: The three components are enclosed in polymer microcapsules (1-10 microns) that protect the chemistry and can be printed onto fabrics or incorporated into fibers during spinning.

- Screen-Printed or Coated: The microcapsules are mixed with a binder and applied to fabric surfaces in specific patterns.

Key parameters to select are the transition temperature (typically 28-34°C for body-responsive designs, or 15-25°C for environment-responsive) and the color shift (e.g., colored to colorless, blue to pink, etc.). According to technical data from color specialists like LCR Hallcrest, modern leuco dyes can achieve 10,000+ reliable color cycles with proper formulation.

What are the Advantages of Liquid Crystal Thermochromics?

Cholesteric liquid crystals (CLCs) offer a different mechanism, reflecting specific wavelengths of light based on the helical pitch of their molecular structure, which changes with temperature. This creates a rainbow iridescent effect that shifts through multiple colors (red, green, blue) over a temperature range (e.g., 5-10°C range). They provide a more dynamic, high-tech aesthetic but are generally more expensive and sensitive. They are usually applied as a thin film laminate onto textile substrates. For mask accents or logos, CLCs create a striking, attention-grabbing effect that responds subtly to breath temperature or ambient air.

What Thermal Activation and Control Mechanisms Can Be Implemented?

For the camouflage effect to be meaningful and controlled, the system needs a reliable source of temperature change and, in advanced implementations, a way to regulate it.

Can Body Heat and Breath Be Sufficient Activation Sources?

For simple, passive implementations, the wearer's own thermal output is the driver:

- Skin Temperature: Areas of the mask close to the cheeks or nose bridge (typically 32-34°C) can trigger thermochromic materials with transition temperatures in this range, creating patterns that appear or disappear as the mask warms up.

- Exhaled Breath: The warm, humid air from exhalation (around 34-36°C) can be channeled across specific textile areas (e.g., near the vent or mouth area) to trigger localized color changes with each breath—a dynamic, living aesthetic.

This passive approach is elegant and requires no electronics, but its effects are subtle and dependent on individual physiology and ambient conditions.

How are Active Heating Elements Integrated for Precise Control?

For more dramatic or programmable effects, thin, flexible heating elements can be incorporated:

- Conductive Inks or Yarns: Silver, carbon, or graphene-based inks can be printed in micro-circuit patterns between fabric layers. When a small voltage is applied from a compact battery, they generate gentle, localized heat.

- Joule Heating Fabrics: Woven or knitted fabrics containing metallic or conductive polymer fibers can act as distributed heaters.

This active approach allows for programmable patterns: specific zones of the mask can be warmed on demand via a smartphone app or a simple button, creating color-change graphics, messages, or indicators. It also ensures the effect works consistently regardless of the wearer's body heat or environment.

What Textile Integration and Durability Methods Ensure Longevity?

The harsh reality of mask use—flexing, moisture, cleaning, and abrasion—poses significant challenges for delicate thermochromic systems. Robust integration is key to a viable product.

How are Thermochromic Materials Applied to Fabric Durably?

The application method critically affects lifespan:

- Printing (Screen or Digital): Microcapsules are mixed with a polymer binder and printed onto the fabric surface. A protective overcoat or laminate is often added to shield the capsules from abrasion and moisture. This is ideal for precise patterns.

- Padding or Exhaustion Dyeing: The fabric is immersed in a bath containing the microencapsulated dyes, and the capsules are forced into the fiber interstices. This can create a more uniform, all-over effect that is less prone to surface wear.

- Incorporation into Fibers: During synthetic fiber (e.g., polyester) production, the microcapsules can be added to the polymer melt before extrusion, embedding the thermochromic material within the fiber itself. This offers the greatest durability for washing and wear but is more complex and limits color vibrancy.

Partnering with specialty chemical and textile finishers like ColorChange is often necessary for access to optimized, durable formulations.

How Do You Address the Challenges of Washing and Moisture?

Masks need to be cleaned regularly. Thermochromic systems are sensitive to detergents, high heat, and mechanical agitation. Implementation strategies include:

- Cold Water Wash Instructions: Clearly labeling for gentle, cold hand wash.

- Robust Encapsulation: Using tougher polymer shells (e.g., melamine-formaldehyde) for the microcapsules.

- Protective Top Layers: Laminating a thin, transparent, and breathable polyurethane film over the printed design.

- Localized Application: Placing the thermochromic elements on less-abraded, non-stretch areas of the mask pattern (e.g., the rigid nose bridge cover or cheek panels rather than the stretching chin area).

What Aesthetic and Functional Design Paradigms Are Possible?

Beyond the "cool factor," thoughtful design can leverage thermal camouflage to serve genuine aesthetic or communicative functions.

Can Patterns Be Designed to Enhance Facial Features or Express Mood?

Yes, through strategic pattern placement:

- Contour Highlighting: Using thermochromic inks along the cheekbones or jawline that become visible with body heat, subtly enhancing facial contours even when most of the face is covered.

- Expressive Graphics: Patterns that change from a neutral state to a more vibrant or intricate design as the mask warms, symbolizing the "activation" of the wearer's presence or energy. For example, a simple line drawing that fills with color.

- Mood Indication: While not a precise medical tool, a broad correlation between skin temperature and stress/exertion could allow a mask's color shift to serve as a simple, external indicator of the wearer's physiological state—cool/calm colors when relaxed, warm/energetic colors when active or stressed.

How Can Camouflage Serve a Functional Purpose?

- Environmental Blending: Using a palette and pattern that shifts to better match different lighting conditions (cool office light vs. warm sunset) for a more cohesive personal style.

- Brand Interaction: For events or retail, masks could change to display a brand logo or message only when the wearer is in a specific, warmed-up location (like a store entrance with a heat trigger).

- Thermal Feedback: In a mask designed for sports, a color change could indicate when the internal temperature is rising to a level that suggests the filter is becoming moist or less effective, prompting the user to take a break or change the mask.

Conclusion

Implementing thermal camouflage textiles for mask aesthetics is a multidisciplinary endeavor that blends creative design with rigorous material science and engineering. Success hinges on selecting the right thermochromic system (leuco dyes for robustness, liquid crystals for drama), integrating it durably into the textile substrate, and designing an activation method (passive body heat or active electronics) that delivers the desired user experience. While challenges in wash durability and consistent performance exist, they are being addressed through advanced encapsulation and application techniques. The result is a new category of expressive, adaptive personal gear that transforms the mask from a utilitarian object into a dynamic canvas for personal expression and interactive design.

Ready to explore how thermal camouflage textiles can differentiate your mask line with cutting-edge, adaptive aesthetics? Contact our Business Director, Elaine, at elaine@fumaoclothing.com to discuss material sourcing, design collaboration, and prototyping for your next innovative mask collection.