The integration of advanced technologies into wearable devices and protective equipment brings unprecedented capabilities but also introduces complex biocompatibility challenges. ISO 10993 standards provide the essential framework for evaluating biological safety, yet navigating this comprehensive regulatory landscape can be daunting for manufacturers developing skin-contact technologies. For product developers, regulatory specialists, and quality managers working on smart masks, wearable sensors, and skin-contact electronics, mastering ISO 10993 compliance is not optional—it's fundamental to market access and user safety.

ISO 10993 biocompatibility standards provide a systematic, risk-based framework for evaluating the potential biological risks of medical devices and similar products that contact the human body, requiring manufacturers to assess cytotoxicity, sensitization, irritation, and systemic toxicity based on the nature and duration of body contact. These standards transform subjective safety assessments into objective, scientifically validated processes that protect users while enabling innovation. Successful navigation requires understanding the standard's risk classification system, test selection methodology, and documentation requirements specific to skin-contact applications.

The global medical device market is projected to reach $612 billion by 2025, with wearable and skin-contact technologies representing the fastest-growing segment. Regulatory databases indicate that 15-20% of medical device submissions face delays due to inadequate biocompatibility documentation, making early and strategic compliance planning essential. Let's explore the practical pathways for navigating ISO 10993 for skin-contact technologies.

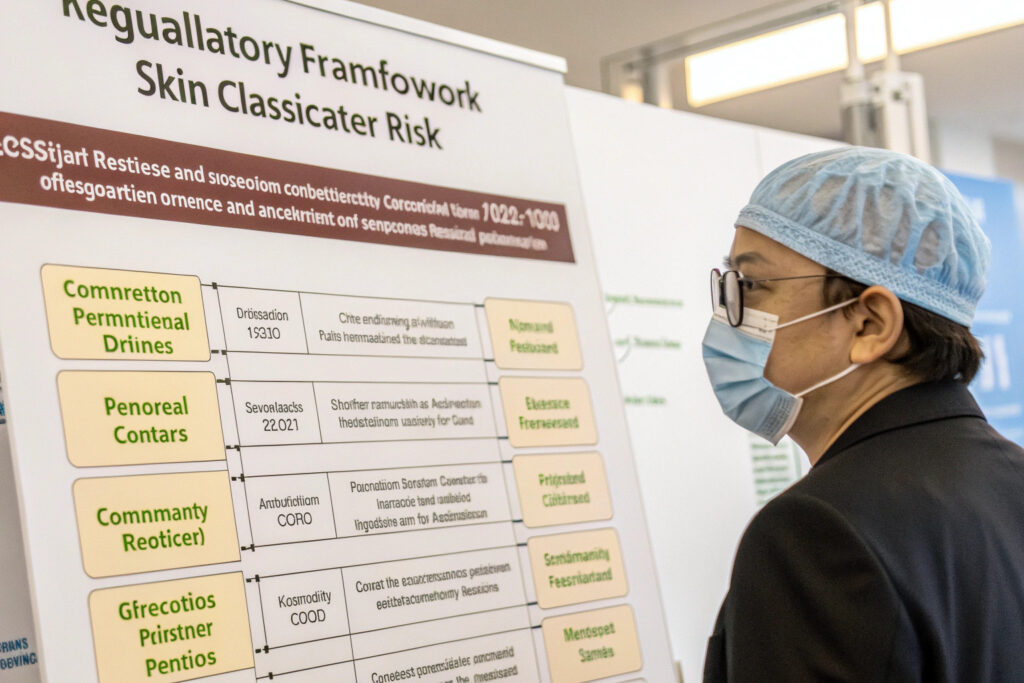

What Is the ISO 10993 Risk Classification Framework?

The foundation of ISO 10993 compliance is understanding the device categorization system that determines testing requirements based on contact nature, duration, and bodily location.

How Does Contact Duration Impact Testing Requirements?

ISO 10993 defines three contact duration categories: limited exposure (<24 hours), prolonged exposure (24 hours to 30 days), and permanent contact (>30 days). Skin-contact masks typically fall into prolonged exposure category (24 hours to 30 days) unless designed for continuous multi-month wear. According to the FDA's Use of ISO 10993-1 guidance, prolonged contact devices require more extensive testing than limited contact devices but less than permanent implants. Our classification methodology uses worst-case scenario planning, typically categorizing reusable masks as prolonged contact even if single-use periods are shorter, ensuring comprehensive safety coverage.

What Body Contact Determinations Apply to Facial Devices?

The standard distinguishes between intact skin contact (most masks), breached or compromised skin contact (wound care devices), and mucosal membrane contact (nasal/oral interfaces). Facial masks primarily involve intact skin contact but may have areas contacting mucosal membranes at transition zones. Research published in the Journal of Biomedical Materials Research indicates that materials safe for intact skin may not be suitable for mucosal contact without additional testing. Our assessment maps specific device areas to contact types, with different testing protocols for nose bridge materials (potential mucosal contact) versus cheek area materials (intact skin contact).

What Are the Essential Biocompatibility Test Requirements?

ISO 10993-1 specifies a matrix of required biological evaluations based on device categorization. Understanding this testing matrix is crucial for planning appropriate and efficient biocompatibility assessment.

Which Tests Are Mandatory for All Skin-Contact Devices?

Cytotoxicity testing (ISO 10993-5) is universally required for all medical devices, evaluating whether materials release chemicals that damage cells. This in vitro test uses cell cultures exposed to material extracts, measuring cell death, inhibition, or morphological changes. According to validation studies from the National Toxicology Program, properly conducted cytotoxicity tests predict 85-90% of material toxicity concerns. Our testing protocol includes both direct contact and extract methods using mouse fibroblast cells (L929) and human keratinocyte cells (HaCaT) to assess different cellular responses.

What Additional Tests Apply Based on Contact Duration?

For prolonged skin contact (24 hours to 30 days), ISO 10993 requires: sensitization testing (ISO 10993-10), irritation or intracutaneous reactivity testing (ISO 10993-10 or 10993-23), and material-mediated pyrogenicity testing (ISO 10993-11). Sensitization testing typically uses guinea pig maximization tests or murine local lymph node assays to assess allergic potential. Research in Regulatory Toxicology and Pharmacology indicates that combined testing approaches (in vitro and in vivo) provide the most reliable sensitization prediction for new material formulations. Our testing strategy employs a tiered approach starting with in vitro assays (DPRA, KeratinoSens) followed by confirmatory animal testing only when needed, reducing animal use while ensuring safety.

How to Prepare the Biological Evaluation Report (BER)?

The Biological Evaluation Report is the comprehensive document that demonstrates compliance and serves as the primary evidence for regulatory submissions.

What Material Characterization Data Is Essential?

Comprehensive material characterization forms the foundation of the BER and must include: complete material composition (including additives, processing aids, colorants), physicochemical properties, potential leachables and extractables profiles, and manufacturing process details. According to guidance from the Medical Device Innovation Consortium, material characterization should be sufficiently detailed to allow identification of all potential biological risks. Our characterization protocols include Fourier-transform infrared spectroscopy (FTIR), gas chromatography-mass spectrometry (GC-MS) for extractables, and inductively coupled plasma (ICP) for metal content, creating comprehensive material profiles that support risk assessment.

How Should Risk Assessment Be Structured and Documented?

The risk assessment must follow ISO 14971 principles, identifying potential biological hazards, estimating associated risks, implementing control measures, and verifying effectiveness. For skin-contact devices, key considerations include: chemical release during use, particulate generation, thermal effects from electronics, and electromagnetic interactions. Documentation should include: hazard analysis worksheets, risk estimation matrices, control measure verification data, and residual risk evaluation. Our risk assessment methodology uses failure mode and effects analysis (FMEA) specifically adapted for biological risks, with quantitative risk scoring that prioritizes testing and mitigation efforts.

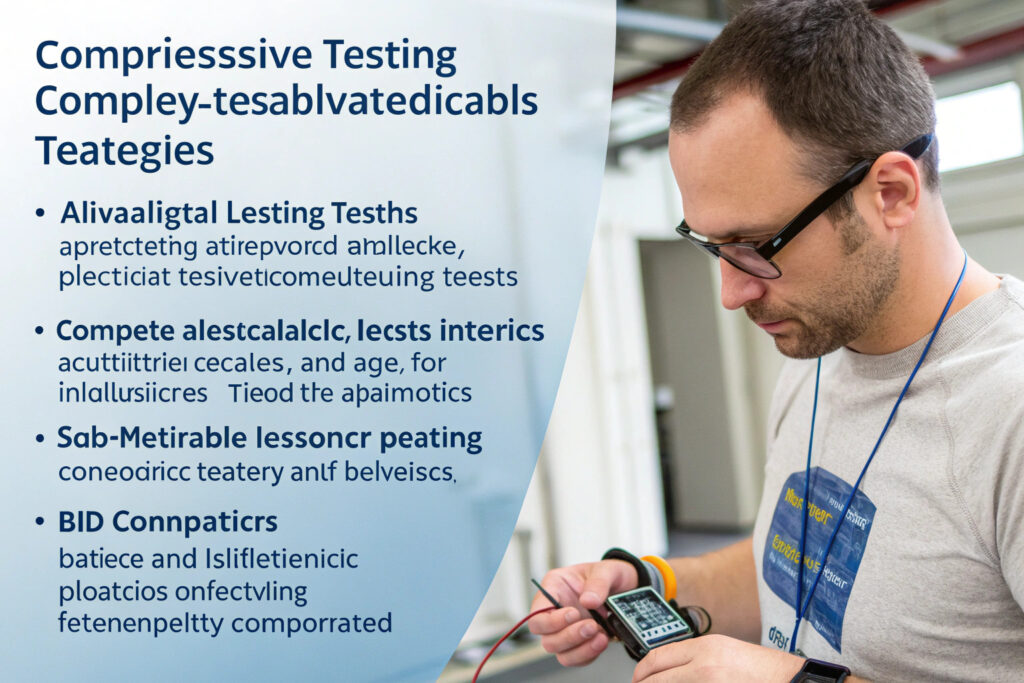

What Are Practical Testing Strategies for Complex Wearables?

Modern skin-contact technologies often combine multiple materials, electronics, and dynamic components that require innovative testing approaches beyond traditional material evaluation.

How to Test Integrated Electronic Components?

Electronic components require specialized evaluations including: assessment of electromagnetic field effects on tissues, evaluation of battery safety under fault conditions, testing of thermal management systems to prevent burns, and assessment of potential electrochemical reactions at electrode-skin interfaces. According to emerging guidelines from the IMDRF's Software as Medical Device working group, electronic wearables should undergo risk-based testing that addresses both material biocompatibility and functional safety. Our testing protocol for electronic components includes: infrared thermography to map surface temperatures during operation, electrochemical testing of electrode materials, and specialized cytotoxicity testing using extracts generated during device operation rather than just material extracts.

What Strategies Address Dynamic Wear and Degradation?

Reusable devices undergo material changes during normal use including: mechanical degradation from flexing, chemical changes from cleaning, environmental degradation from UV/sweat exposure, and biological fouling from skin oils/microbes. Testing should evaluate not just initial biocompatibility but also performance after simulated use. Research published in Biomaterials demonstrates that accelerated aging protocols can effectively predict long-term biocompatibility changes. Our testing includes material evaluations after: simulated cleaning cycles (following manufacturer's instructions), mechanical flexing equivalent to 30-90 days of use, and environmental exposure simulating worst-case storage and use conditions.

How to Manage Ongoing Compliance and Changes?

Biocompatibility is not a one-time assessment but an ongoing process requiring management of material changes, manufacturing modifications, and new clinical evidence.

What Changes Trigger Re-Evaluation Requirements?

The FDA's guidance identifies specific changes requiring biocompatibility re-evaluation including: material composition changes (even small percentage changes), manufacturing process changes affecting material properties, sterilization method changes, intended use changes (new patient populations, longer wear times), and new clinical information suggesting safety concerns. According to analysis of FDA 510(k) submission feedback, material and process changes account for 40-50% of biocompatibility-related submission deficiencies. Our change control system uses a risk-based assessment matrix that categorizes changes as major, moderate, or minor, with corresponding testing requirements for each category.

How Should Supplier Changes Be Managed?

Supplier changes for raw materials require careful evaluation even when chemical specifications appear identical, as different manufacturing processes can introduce different impurities or material characteristics. Best practice involves: comparative testing of materials from old and new suppliers, evaluation of supplier's quality systems and change control processes, and potentially updating the device master file. Industry guidance from the Association for the Advancement of Medical Instrumentation recommends maintaining supplier audit programs and material equivalency protocols. Our supplier management includes: initial biocompatibility testing of materials from new suppliers, regular supplier audits focusing on process consistency, and maintaining inventories that allow parallel testing during supplier transitions.

Conclusion

Navigating ISO 10993 biocompatibility requirements for skin-contact technologies requires a systematic, risk-based approach that begins with proper device categorization and extends through comprehensive testing, thorough documentation, and ongoing compliance management. The most successful implementations integrate biocompatibility considerations from the earliest design stages, creating safer products while streamlining regulatory pathways. As wearable technologies continue to evolve with new materials and integrated electronics, mastering ISO 10993 compliance becomes increasingly critical for market success and user safety.

Ready to navigate ISO 10993 biocompatibility for your skin-contact technology products? Contact our Business Director, Elaine, at elaine@fumaoclothing.com to discuss how our regulatory expertise and testing partnerships can help you efficiently achieve compliance for your innovative wearable devices. Our team specializes in guiding complex skin-contact technologies through the biological evaluation process with optimal efficiency and thoroughness.