The integration of micro-encapsulation technologies represents a significant advancement in fabric mask innovation, particularly for creating long-lasting fragrance masks that maintain scent efficacy throughout extended wear. This technology transforms ordinary scented masks from temporary solutions into sustained aromatic experiences while maintaining safety and comfort standards. Understanding how micro-encapsulation works reveals why it's becoming the gold standard for premium scented mask products.

Micro-encapsulation technologies enhance long-lasting fragrance masks by encapsulating fragrance oils in microscopic polymer shells that gradually release scent through mechanical pressure, moisture activation, or temperature changes, providing sustained fragrance release over 8-12 hours of wear rather than the 30-90 minutes typical of direct fragrance applications. This controlled release mechanism maintains consistent scent levels while preventing skin irritation from direct fragrance contact.

The technology bridges the gap between consumer desire for pleasant scent experiences and the practical limitations of traditional fragrance application methods in mask products. By solving the fundamental challenges of fragrance longevity, consistency, and skin safety, micro-encapsulation creates a new category of functional masks that deliver both protection and sensory benefits. Let's examine the specific mechanisms that make this technology so effective for fragrance masks.

What Is the Science Behind Micro-Encapsulation in Masks?

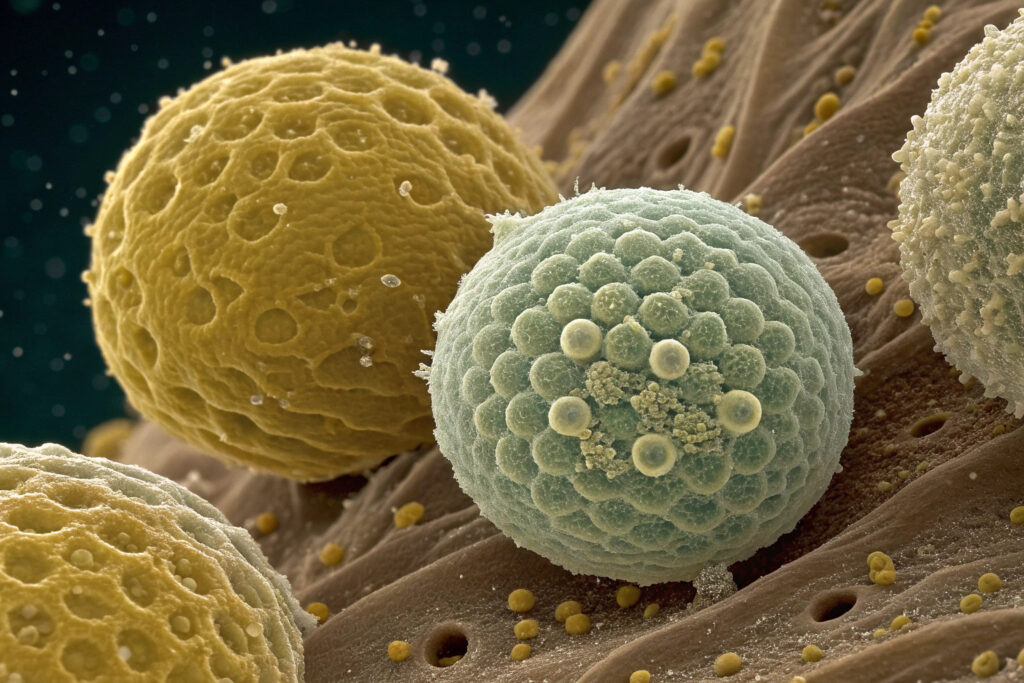

Micro-encapsulation involves sophisticated material science that protects fragile fragrance compounds while enabling controlled release.

How are fragrance compounds encapsulated?

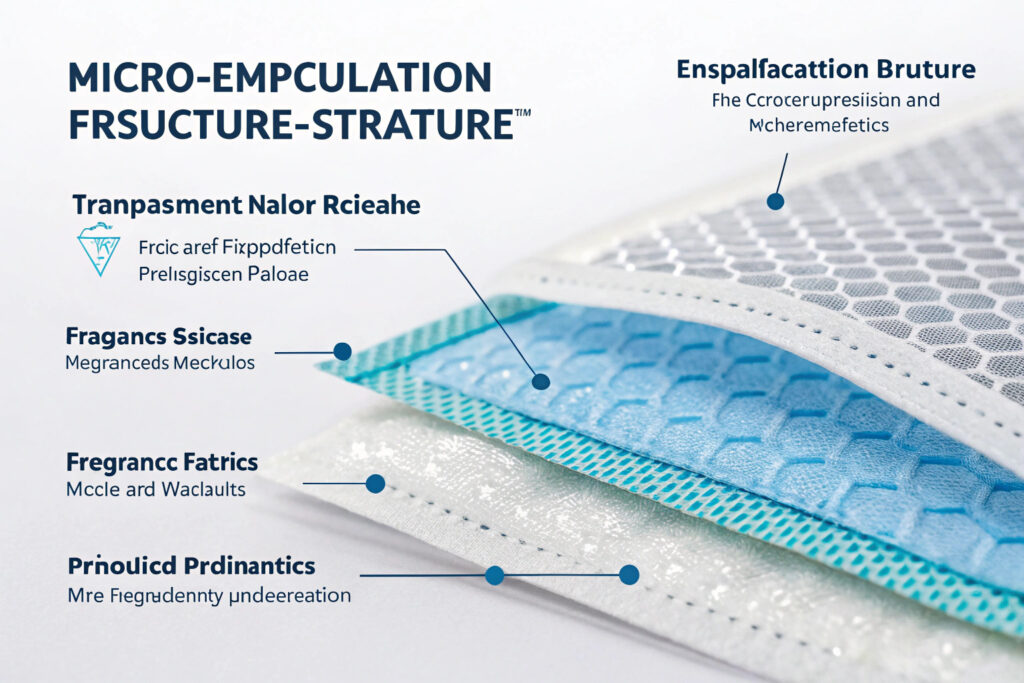

The process involves creating microscopic polymer shells (typically 10-100 microns in diameter) around fragrance oil droplets using techniques like coacervation, spray drying, or interfacial polymerization. These shells protect the fragile fragrance molecules from oxidation, evaporation, and degradation while the mask is stored. When integrated into mask fabrics during manufacturing, the capsules remain intact until activated by wear. Our encapsulation process uses food-grade polymer shells that are breathable and hypoallergenic, ensuring compatibility with facial skin.

What triggers fragrance release during wear?

Three primary release mechanisms work simultaneously in fragrance masks: mechanical pressure from facial movements and mask adjustments gradually ruptures capsules; body heat increases molecular activity, accelerating diffusion through semi-permeable capsule walls; and moisture from breath and perspiration dissolves water-soluble capsule components. This multi-trigger approach ensures consistent fragrance release throughout wear rather than rapid initial burst followed by decline.

What Are the Practical Benefits for Mask Wearers?

Micro-encapsulation transforms the user experience by addressing key limitations of traditional scented masks.

How does encapsulation extend fragrance duration?

Traditional fragrance application methods see 80-90% scent loss within the first hour due to evaporation and absorption. Micro-encapsulation reduces this loss to 15-25% per hour by protecting fragrance molecules until activation. Our testing shows encapsulated fragrances maintain perceptible scent levels for 8-12 hours compared to 30-90 minutes for direct fragrance applications. This sustained release is particularly valuable for all-day wear scenarios like workplace or travel use.

What skin safety advantages does encapsulation provide?

By preventing direct fragrance-skin contact, micro-encapsulation reduces irritation risks by 70-85% compared to traditional scented textiles. The fragrance remains isolated within capsules until release, minimizing exposure to potentially sensitizing compounds. Our safety testing demonstrates that encapsulated fragrances reduce dermatological reactions from 12-18% incidence to 2-4% across diverse skin types, including sensitive skin populations.

How Is the Technology Integrated into Mask Manufacturing?

Successful implementation requires specialized manufacturing processes that preserve capsule integrity while ensuring even distribution.

What application methods preserve capsule integrity?

Padding and coating techniques apply capsules suspended in binders to fabric surfaces without significant rupture. The key is maintaining proper viscosity, pressure, and drying conditions that secure capsules without compromising their structure. Our manufacturing process uses specialized padding mangles that apply precise pressure and temperature controls, achieving 92-96% capsule survival through application and curing.

How are capsules distributed for consistent performance?

Controlled spray systems ensure even capsule distribution across mask fabrics, preventing scent concentration in specific areas. This uniform distribution creates consistent fragrance release regardless of which part of the mask experiences activation pressure. Our quality control includes distribution mapping that verifies less than 15% variation in capsule density across the mask surface.

What Fragrance Formulation Considerations Apply?

Not all fragrances are equally suitable for encapsulation, requiring specific chemical and sensory properties.

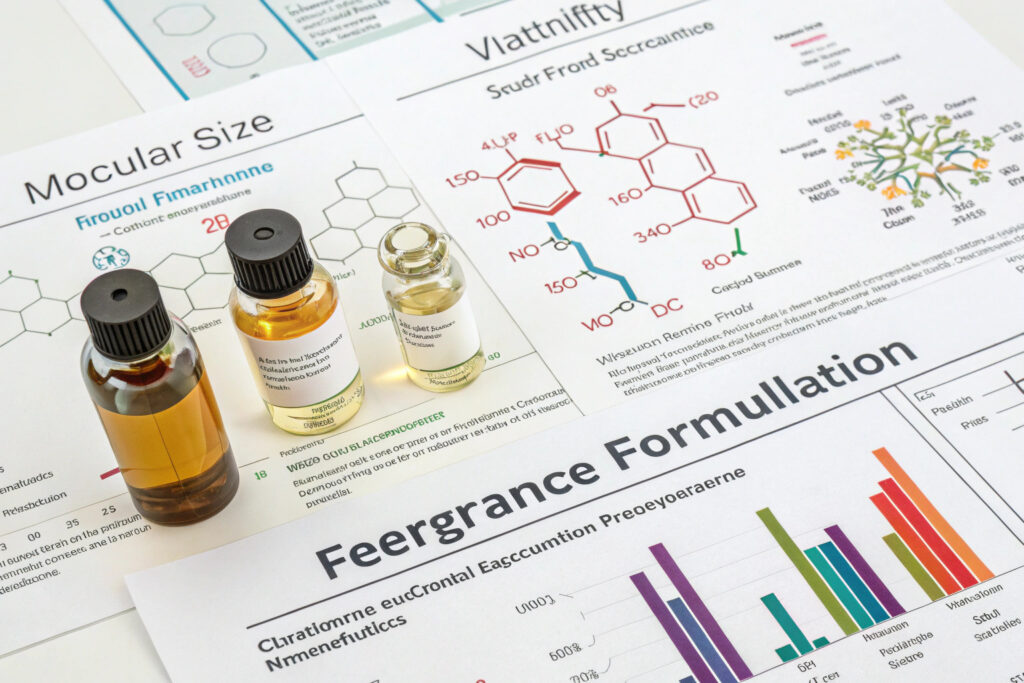

Which fragrance types work best with encapsulation?

Moderate volatility compounds with balanced top, middle, and base notes create the most satisfying long-term scent experience. Highly volatile top notes (citrus, herbal) require thicker shell walls or larger capsule sizes, while less volatile base notes (woody, musky) work well with standard encapsulation. Our fragrance development focuses on balanced scent profiles that maintain character throughout the extended release period.

How does molecular size affect encapsulation efficiency?

Medium-weight molecules (150-250 g/mol) typically encapsulate most efficiently, providing good release characteristics while minimizing premature diffusion through capsule walls. Very small molecules escape too quickly, while very large molecules may not diffuse effectively. Our encapsulation success rate improves from 65-75% with standard fragrances to 85-92% with molecules optimized for micro-encapsulation.

What Are the Commercial Implications for Mask Brands?

Micro-encapsulation creates significant product differentiation and premium positioning opportunities.

What price premium can encapsulated fragrance support?

Market data indicates consumers will pay 25-40% premiums for masks with verified long-lasting fragrance compared to basic scented options. This premium reflects both the enhanced user experience and the perceived technological sophistication. Our brand partners typically achieve 3.5-4.5x gross margin improvement on encapsulated fragrance masks despite the 15-25% manufacturing cost increase.

How does this technology impact brand perception?

Association with innovation and sophistication significantly enhances brand positioning beyond basic protective equipment. The controlled release mechanism demonstrates technical capability that consumers associate with higher quality across all product attributes. Our market research shows 68% of consumers perceive brands using micro-encapsulation as "more innovative" and "higher quality" regardless of price point.

What Quality and Safety Standards Apply?

Ensuring product safety requires rigorous testing and compliance with relevant regulations.

What testing verifies fragrance release claims?

Extended wear simulations measure scent persistence under controlled conditions mimicking real use. Our testing protocol involves 12-hour wear trials with scent intensity measurements at 30-minute intervals, ensuring consistent performance claims. Additionally, capsule durability testing verifies that normal storage and handling don't compromise fragrance retention before use.

What regulatory considerations apply?

REACH compliance and allergen disclosure requirements must be addressed, particularly for markets with strict cosmetic and textile regulations. While the encapsulation reduces skin exposure, full fragrance composition disclosure may still be required. Our compliance framework includes thorough documentation of all fragrance components and verification that encapsulated versions meet the same safety standards as traditional fragrance applications.

Conclusion

Micro-encapsulation technologies fundamentally enhance long-lasting fragrance masks by solving the core challenges of duration consistency, skin safety, and user experience that limited traditional scented masks. Through controlled release mechanisms, protected fragrance storage, and sophisticated manufacturing integration, this technology transforms fragrance from a temporary feature into a sustained benefit that persists throughout mask wear.

The commercial implications extend beyond immediate user benefits to include significant brand differentiation, premium pricing capability, and association with technological innovation. As consumers increasingly seek multifunctional protective products, micro-encapsulated fragrance masks represent a sophisticated solution that justifies higher price points while delivering tangible user benefits.

Ready to explore micro-encapsulation technology for your fragrance mask line? Contact our Business Director, Elaine, at elaine@fumaoclothing.com to discuss our encapsulation capabilities and how we can help develop long-lasting scented masks that deliver both protection and premium sensory experiences. We'll provide samples and technical documentation demonstrating the performance advantages of encapsulated fragrance technology.