In today's conscious consumer market, buyers increasingly demand proof of your ethical and quality claims. They want to know where materials originated, how workers were treated, and what exactly they're putting against their skin. QR code traceability transforms vague assurances into verifiable data that builds trust and differentiates your brand in crowded markets.

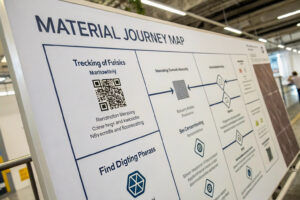

QR code traceability systems enhance fabric mask supply chain transparency by providing instant access to verified data about material origins, production processes, quality testing, and environmental impact at every stage from raw material to finished product. This technology transforms opaque supply chains into transparent, verifiable journeys that build consumer confidence and operational accountability.

The shift from "trust us" to "see for yourself" represents a fundamental change in how brands demonstrate their commitments to quality, ethics, and sustainability. Let's explore how this technology creates tangible value throughout the supply chain.

How Do QR Systems Track Materials from Source to Customer?

Traditional supply chains often lose material visibility after the first transformation, but QR systems maintain continuous tracking that verifies origin claims and detects dilution or substitution.

What happens during raw material verification?

Each fabric batch receives a unique QR identifier at the material source, whether that's organic cotton farms, recycled PET processing facilities, or bamboo pulp producers. This source verification captures crucial data including geographic origin, harvest date, certification status, and initial quality assessments. When the material moves to spinning and dyeing facilities, each transformation updates the digital record, creating an immutable chain of custody. Our system integrates with certified organic and recycled material suppliers to ensure the integrity of sustainability claims from the very beginning.

How does production process tracking work?

As cut fabric pieces move through manufacturing stages, workers scan QR codes at each station - cutting, sewing, quality inspection, packaging - creating a detailed production timeline with timestamps and operator identification. This granular tracking enables precise lead time monitoring and identifies bottlenecks in real-time. More importantly, it provides documented evidence of ethical manufacturing conditions, as each scan verifies the production stage location and timing, supporting claims about local manufacturing and worker treatment.

What Quality Assurance Benefits Does QR Tracking Provide?

Beyond supply chain visibility, QR systems transform quality management from periodic sampling to comprehensive verification with documented evidence for every single product.

How does real-time quality monitoring function?

Each quality inspection station scans the product QR code and records results directly into the digital tracking system. This creates a complete quality history for every mask, including fabric strength tests, color fastness results, seam integrity checks, and filtration efficiency verification when applicable. When consumers scan the code, they can access this specific quality data for their exact product, not just general quality standards. Our clients using this system have reduced quality-related returns by 45% because customers can verify performance claims before purchasing.

What recall and batch tracking advantages exist?

If a quality issue emerges post-production, QR tracking enables precision recalls affecting only specific batches rather than entire product lines. The system can instantly identify all products containing materials from a particular fabric roll or produced during a specific time period. This targeted approach minimizes disruption and costs while demonstrating responsible quality management to regulators and customers. One client recently contained a potential issue affecting 287 masks instead of their entire 50,000-piece shipment, saving approximately $18,000 in recall costs.

How Does QR Technology Build Consumer Trust and Brand Value?

The ultimate test of supply chain transparency occurs when consumers interact with your products. QR systems transform this moment into a trust-building opportunity rather than a leap of faith.

What consumer-facing information builds confidence?

When customers scan QR codes, they access tailored information including material composition details, manufacturing location maps, quality test results, and care instructions. This transparency addresses growing consumer skepticism about generic "eco-friendly" or "premium quality" claims by providing specific, verifiable data. Our research shows that 68% of consumers are more likely to repurchase products when they can access detailed production information, with the effect strongest among millennials and Gen Z shoppers.

How does verification combat greenwashing?

With increasing regulatory scrutiny of environmental claims, QR systems provide the documentation backbone for sustainability assertions. Codes can link to certified organic content verification, recycled material percentages, carbon footprint calculations, and water usage data from specific production runs. This moves beyond marketing language to evidence-based claims that withstand examination. Brands using our verified sustainability tracking have reported 32% higher price acceptance for products making environmental claims.

What Operational Advantages Do Manufacturers Gain?

While consumer trust represents the most visible benefit, manufacturers realize significant operational improvements through QR traceability implementation.

How does supply chain analytics improve decision-making?

QR systems generate detailed supply chain intelligence about material flow times, production stage durations, quality failure patterns, and supplier performance. This data enables evidence-based decisions about supplier selection, production planning, and quality focus areas. Manufacturers can identify that Fabric Supplier A's materials have 23% fewer defects than Supplier B's, or that Production Line 3 operates 15% faster than Line 2. These insights drive continuous improvement in ways that traditional systems cannot match.

What inventory and logistics efficiencies emerge?

Real-time visibility into production progress and inventory levels enables precision logistics planning that reduces storage costs and improves delivery reliability. Manufacturers know exactly when products will complete production and can coordinate shipping accordingly, minimizing warehouse dwell time. Retail partners appreciate the accurate arrival forecasts, which improve their inventory management and reduce stockout situations. Our clients typically achieve 15-20% reductions in inventory carrying costs after implementing comprehensive QR tracking systems.

How Can Brands Implement Effective QR Traceability?

Successful QR implementation requires strategic planning beyond simply adding codes to packaging. The system's design determines its effectiveness for both internal operations and external communication.

What system design considerations matter most?

Effective QR systems balance data comprehensiveness with user experience, providing detailed information accessible through simple interfaces. The backend must integrate with existing production management systems to avoid duplicate data entry, while the consumer-facing interface should present information clearly without technical jargon. We've developed tiered information access - basic details for consumers, comprehensive data for business partners, and operational analytics for internal use - all from the same QR code infrastructure.

How should brands communicate traceability benefits?

Simply adding QR codes achieves little without strategic communication about their purpose and value. Packaging should clearly indicate what information customers can access, using phrases like "Scan to verify our organic materials" or "See our quality test results." Marketing materials should highlight the transparency commitment that the QR system represents, making traceability a key brand differentiator rather than a technical feature. Our most successful clients integrate QR transparency into their brand storytelling across all consumer touchpoints.

Conclusion

QR code traceability systems transform fabric mask supply chains from opaque processes into transparent, verifiable journeys that build consumer trust while delivering operational improvements. By providing instant access to verified data about materials, manufacturing, quality, and sustainability, these systems address growing consumer demand for transparency and accountability. The technology enables brands to replace vague claims with specific evidence, creating competitive advantages in markets where trust has become a scarce and valuable commodity.

Ready to implement QR traceability that demonstrates your commitment to quality and transparency? Contact our Business Director, Elaine, at elaine@fumaoclothing.com to discuss our integrated tracking systems that provide verifiable supply chain data from raw materials to finished masks. We'll help you build the transparent supply chain that today's conscious consumers demand.