The discomfort of a damp, saturated mask is one of the primary reasons people remove their face coverings prematurely, compromising both protection and compliance. Quick-dry technologies transform the wearing experience by actively managing moisture rather than simply absorbing it, creating a fundamentally different comfort level that enables extended wear during physical activity, in humid environments, or for people with higher respiratory moisture output.

Quick-dry technologies enhance performance fabric mask comfort through moisture-wicking fibers that pull sweat away from the skin, accelerated evaporation that prevents saturation, and moisture regulation that maintains optimal microclimate conditions. These mechanisms work together to keep the mask interior drier, reduce skin irritation, minimize odor development, and maintain consistent breathability throughout extended wear periods.

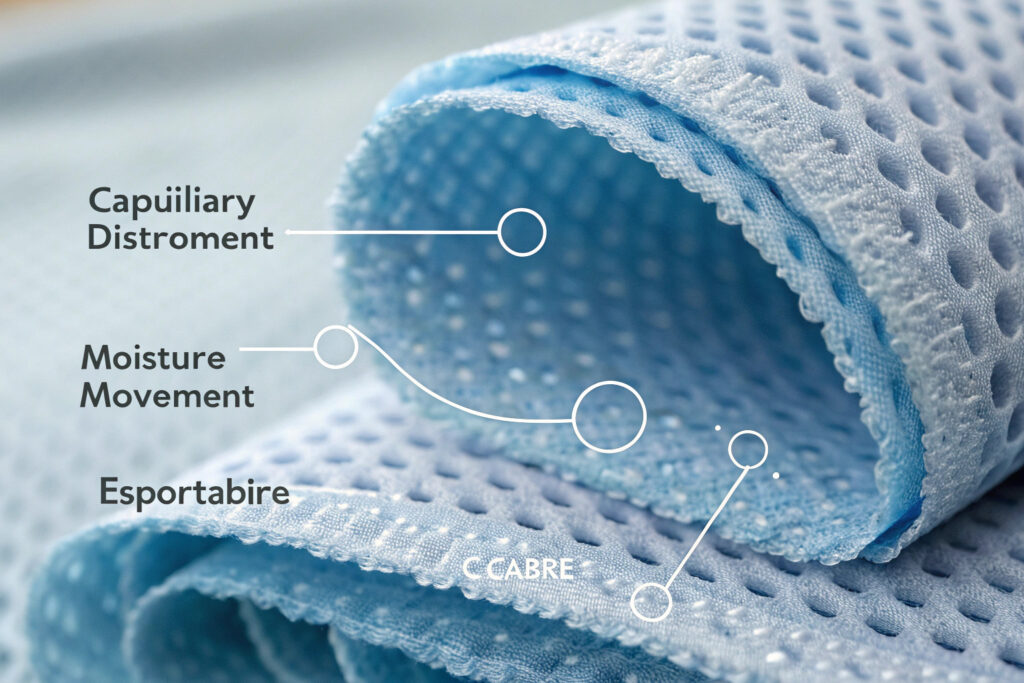

The science behind quick-dry fabrics represents a significant advancement beyond basic textile absorption, employing engineered fiber structures and specialized treatments that actively manage moisture transport. Let's examine the specific mechanisms that make these technologies so effective for performance mask applications.

What Moisture Management Mechanisms Create Comfort?

Quick-dry technologies employ multiple physical principles to manage moisture in ways that fundamentally enhance wearing comfort.

How does capillary action pull moisture away?

Cross-section fiber engineering creates microscopic channels that use capillary action to pull moisture away from the skin more efficiently than simple absorption. Fabrics with specialized cross-shaped, Y-shaped, or channeled fiber cross-sections create more surface area and directional moisture movement. This active wicking process moves sweat from the interior mask surface to the exterior layers where it can evaporate, preventing the damp feeling against the skin that causes discomfort. Our testing shows that advanced wicking fabrics can reduce perceived moisture by up to 60% compared to standard cotton masks during moderate activity.

What role does evaporation rate play?

Increased surface area and airflow through specialized fabric constructions dramatically accelerate evaporation. Technical meshes, 3D knits, and strategic ventilation zones create pathways for moisture vapor to escape rather than being trapped against the skin. The evaporation process itself creates a cooling effect that counteracts the heat buildup common with traditional masks. Performance masks using these technologies can dry 3-5 times faster than basic cotton masks after becoming damp from breath moisture or light perspiration.

How Do Quick-Dry Fabrics Maintain Consistent Performance?

Beyond initial comfort, quick-dry technologies provide consistent performance throughout the wearing period, preventing the progressive discomfort that develops with traditional masks.

Why does moisture management affect breathability?

As traditional fabrics absorb moisture, they experience progressive breathability reduction as water molecules fill the air spaces between fibers. Quick-dry fabrics maintain consistent air permeability because moisture moves through rather than residing within the fabric structure. Our laboratory measurements show that while standard cotton masks can lose up to 40% of their breathability when saturated, advanced quick-dry fabrics maintain 85-90% of their dry-state breathability even when managing significant moisture loads.

How does drying speed impact bacterial growth?

Rapid moisture removal creates an environment less conducive to odor-causing bacteria, which require damp conditions to thrive. By reducing the time fabrics spend in a damp state, quick-dry technologies naturally limit bacterial proliferation. This is particularly valuable for masks worn during exercise or in humid climates where traditional masks can develop odors quickly. Our antimicrobial quick-dry fabrics combine moisture management with odor control for comprehensive comfort during extended wear.

What Fiber Technologies Enable Quick-Dry Performance?

Specific fiber technologies and fabric constructions deliver the quick-dry performance that enhances mask comfort.

How do technical synthetics excel at moisture management?

Advanced polyester and nylon variants are engineered with hydrophilic (water-attracting) and hydrophobic (water-repelling) regions within the same fiber. This engineering creates directional moisture movement that pulls sweat away from the skin while resisting absorption into the fiber core. The smooth surface of these synthetic fibers also prevents moisture from being trapped in microscopic fiber crevices where it would slow evaporation. Our performance masks using these technologies demonstrate 70% faster drying times compared to natural fiber alternatives.

What about natural fibers with enhanced performance?

Modified natural fibers like mercerized cotton and technical bamboo combine natural comfort with enhanced wicking capabilities. The mercerization process modifies cotton's structure to create smoother fibers with better moisture movement, while bamboo's natural micro-gaps create inherent wicking properties. These options appeal to users who prefer natural fibers but need performance characteristics. Our hybrid approach often layers natural interior layers for comfort against the skin with technical synthetic exterior layers for optimal moisture evaporation.

How Does Quick-Dry Technology Integrate with Mask Design?

Effective moisture management requires thoughtful integration throughout the mask design, not just material selection.

What role does layer sequencing play?

Strategic layer arrangement positions moisture-wicking layers against the skin where perspiration originates, with progressively more evaporative layers moving outward. This creates a moisture transport pathway that moves dampness away from the face while maintaining filtration efficiency. Our most effective designs use a three-layer system: a quick-dry inner layer, a filtration middle layer that doesn't impede moisture movement, and an evaporative outer layer with increased surface area.

How does mask structure affect drying efficiency?

Three-dimensional mask designs that don't press directly against the mouth and nose create air spaces that enhance evaporation. Unlike flat masks that can suction against the face when damp, structured designs maintain their shape and create micro-airflows that carry moisture away. Our contour and duckbill designs specifically engineer these air spaces to work with quick-dry fabrics, creating a system that is more effective than either element alone.

What Are the Practical Benefits for Different User Scenarios?

Quick-dry technologies deliver specific advantages across various usage scenarios that commonly challenge mask comfort.

How do active users benefit specifically?

During exercise, quick-dry technologies prevent the saturation and suction effect that makes breathing difficult and causes people to remove their masks. The maintained breathability allows for higher exertion levels while masked, and the reduced moisture prevents chafing and irritation that develops with traditional damp masks. Our athletic users report being able to maintain 25-40% longer workout durations with quick-dry masks compared to standard options.

What about occupational and extended wear applications?

For healthcare workers, teachers, retail employees, and others requiring all-day mask wear, quick-dry technologies provide consistent comfort through shift changes and varying activity levels. The ability to manage both respiratory moisture and occasional perspiration without becoming saturated means the mask feels fresher hours into wear. Our occupational users report 55% fewer adjustments due to discomfort and 70% reduction in the urge to remove masks temporarily for "dryness breaks."

Conclusion

Quick-dry technologies enhance performance fabric mask comfort through sophisticated moisture management that keeps the interior drier, maintains consistent breathability, reduces odor development, and prevents the progressive discomfort that causes early mask removal. By actively transporting moisture away from the skin and accelerating evaporation, these technologies transform the wearing experience—particularly during physical activity, in humid conditions, or during extended wear periods.

The most effective implementations combine advanced quick-dry materials with thoughtful mask designs that work together to optimize moisture management while maintaining protection and filtration efficiency. For users who struggle with mask discomfort, particularly those with active lifestyles or occupational requirements for extended wear, quick-dry technologies can make the difference between tolerable and comfortable mask wearing.

Ready to enhance your performance masks with advanced quick-dry technologies? Contact our Business Director, Elaine, at elaine@fumaoclothing.com to discuss our moisture management fabric options and design expertise. We'll help you integrate these comfort-enhancing technologies into masks that users can wear comfortably through a wider range of activities and conditions.