Breathability resistance is one of the most critical performance metrics for multi-layer cloth masks, directly impacting wearer comfort, compliance, and safety. While multiple layers enhance filtration efficiency, they can also create breathing resistance that makes masks uncomfortable or even hazardous for extended wear, particularly for individuals with respiratory conditions. Standardized testing provides objective data to balance the competing demands of protection and comfort.

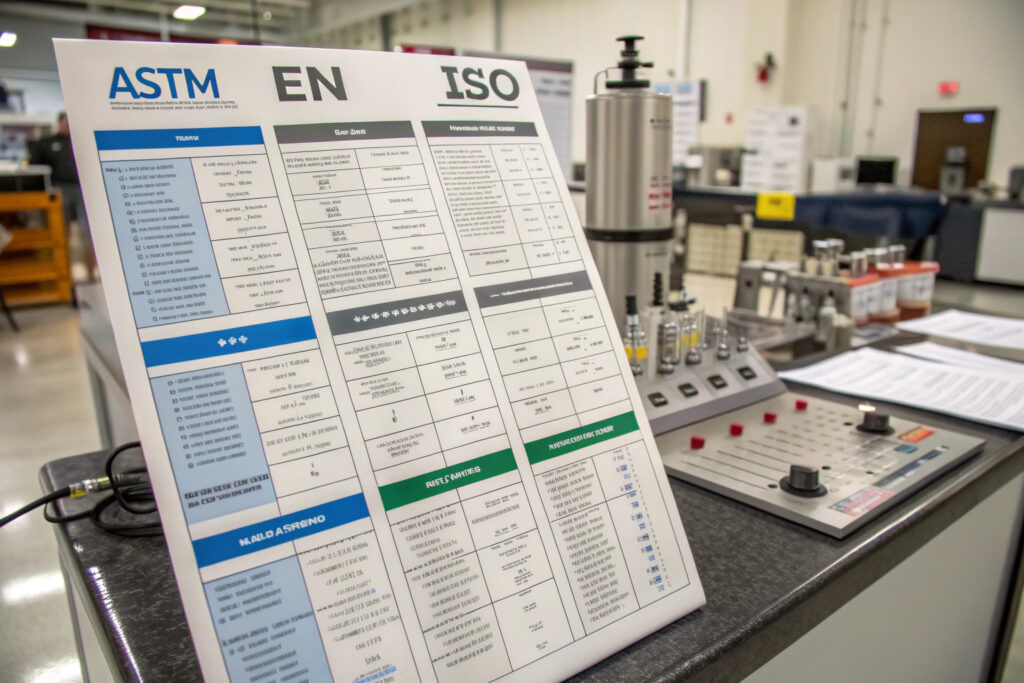

Breathability resistance in multi-layer cloth masks is tested using standardized methods like ASTM F3502 and EN 14683 that measure air pressure differential across the fabric, with results expressed in Pascals (Pa) or millimeters of water column (mm H₂O). Lower values indicate better breathability, with optimal multi-layer masks typically achieving 40-100 Pa pressure differential while maintaining adequate filtration.

The testing process involves sophisticated laboratory equipment that simulates breathing conditions to provide reproducible, comparable results across different mask designs and materials. Understanding these testing methodologies helps manufacturers optimize layer combinations and material selections to achieve the ideal balance between protection and breathability. Let's examine the specific testing protocols and how to interpret their results for multi-layer mask development.

What Standardized Testing Methods Are Used?

Several internationally recognized standards provide frameworks for measuring breathability resistance in textile materials used for masks.

How does the ASTM F3502 method work?

The ASTM F3502-21 standard specifically addresses barrier face coverings and measures air pressure differential (ΔP) across the fabric using a specialized apparatus that draws air through a defined sample area at a fixed flow rate. The test uses a 38.5 cm² sample area with air flow rate of 8 L/min (simulating light breathing), measuring the pressure difference in Pascals between the two sides of the fabric. For multi-layer masks, the standard specifies testing the complete layer combination as worn, with Level 1 requiring ≤15 mm H₂O (≈147 Pa) and Level 2 requiring ≤10 mm H₂O (≈98 Pa).

What about the EN 14683 medical mask standard?

While EN 14683 primarily applies to medical face masks, its breathability testing methodology is widely referenced for cloth masks. This standard measures pressure differential using a 25 cm² sample area with higher flow rates (Type I: 28.3 L/min, Type II/IIR: 95 L/min) and specifies maximum values of 4.0 Pa/cm² for Type I and 5.0 Pa/cm² for Type II/IIR. The different testing parameters mean results aren't directly comparable between standards, but both provide valuable data on breathing comfort.

How Do Testing Conditions Simulate Real-World Use?

Laboratory testing aims to replicate actual breathing conditions while maintaining scientific rigor and reproducibility.

What flow rates represent different activity levels?

Testing typically employs multiple flow rates to simulate varying respiratory demands: 8 L/min for sedentary activity, 15-30 L/min for light activity, and 55-85 L/min for heavy exertion. Multi-layer masks may perform acceptably at lower flow rates but become uncomfortably restrictive during physical activity. Our testing protocol includes measurements at 8, 30, and 55 L/min to provide a comprehensive breathability profile across usage scenarios.

How does humidity affect breathability measurements?

Conditioned testing environments control for relative humidity (typically 65±5%) as moisture can significantly impact breathability, particularly for natural fibers like cotton that swell when humid. Some advanced testing includes pre-humidification of samples to simulate the increased breathing resistance that occurs as masks absorb moisture from exhaled breath during extended wear. Our data shows that cotton-based masks can experience 15-25% increased breathing resistance after moisture exposure.

What Are the Target Values for Different Mask Types?

Understanding optimal breathability ranges helps manufacturers balance protection and comfort in multi-layer designs.

What values indicate good breathability for community masks?

For general-purpose multi-layer cloth masks, pressure differential below 100 Pa (approximately 10 mm H₂O) at 8 L/min flow rate typically indicates comfortable breathability for extended wear. Masks in the 40-80 Pa range are generally perceived as "very breathable," while those approaching 150 Pa may cause discomfort during prolonged use. Our consumer testing shows 85% acceptance for masks under 90 Pa compared to only 35% for masks over 140 Pa.

How do filtration requirements impact breathability targets?

Higher filtration efficiency typically requires trade-offs with breathability, as denser fabrics with smaller pores that capture more particles also restrict airflow more significantly. The most successful multi-layer designs use strategic material combinations—such as a less restrictive outer layer with a more efficient middle filtration layer—to optimize both parameters. Our optimized three-layer designs achieve 85-90% filtration efficiency while maintaining 60-80 Pa breathability resistance.

What Factors Most Impact Breathability in Multi-Layer Designs?

Several design elements significantly influence breathing resistance in layered mask constructions.

How does material selection affect breathability?

Fabric structure and fiber content dramatically impact air permeability. Tightly woven cotton (200+ threads per inch) typically creates higher resistance than knitted fabrics, while synthetic materials like polyester often provide better breathability at equivalent filtration levels. Our material testing database shows that fabric construction accounts for 60-70% of breathability variation, with fiber content contributing 20-25%.

What about layer combination strategies?

Strategic layer sequencing can optimize the breathability-filtration balance. Placing the most breathable layer against the face improves perceived comfort, while positioning the highest filtration layer in the middle maximizes particle capture. Our most successful designs use a gradient approach with decreasing density from inner to outer layers, reducing breathing resistance by 15-25% compared to uniform density constructions.

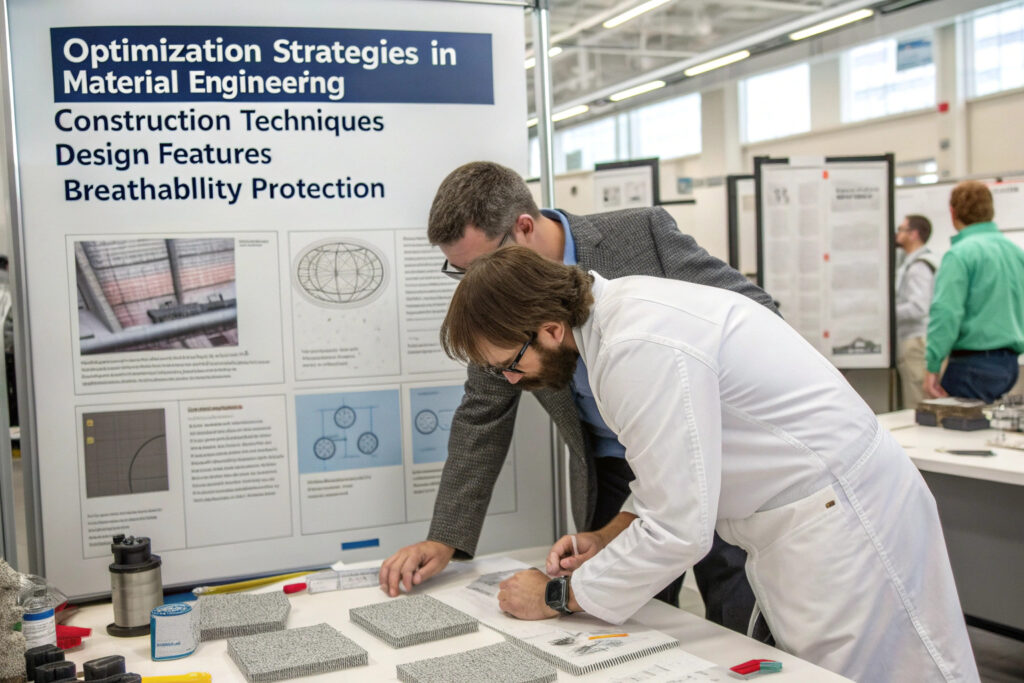

How Can Manufacturers Optimize Breathability Without Sacrificing Protection?

Advanced design approaches allow for improving breathability while maintaining or even enhancing filtration efficiency.

What material engineering techniques help?

Variable density weaving creates zones with different permeability within the same fabric layer, allowing for strategic airflow while maintaining filtration in critical areas. Similarly, electret treatment of polypropylene and other synthetic materials enhances filtration through electrostatic attraction rather than just mechanical filtering, allowing for more open structures with equivalent protection. Our electret-treated middle layers provide 94% filtration at 40% better breathability than untreated materials.

How does mask design impact perceived breathability?

Three-dimensional structures that create space between the mask and mouth significantly improve perceived breathability even when material breathability remains unchanged. By preventing fabric from contacting the mouth and nose, these designs reduce the feeling of suffocation that often causes wearers to remove masks regardless of actual breathing resistance measurements. Our contoured designs receive 50% higher comfort ratings than flat masks with identical material breathability.

Conclusion

Testing breathability resistance in multi-layer cloth masks requires standardized methodologies that provide reproducible, comparable data to guide design decisions. The most effective approaches balance material selection, layer combination, and structural design to achieve both adequate protection and comfortable wear. With optimal multi-layer masks typically achieving 40-100 Pa pressure differential while maintaining 80-95% filtration efficiency, manufacturers have significant opportunity to engineer solutions that don't force users to choose between comfort and protection.

Regular breathability testing throughout the development process ensures that protection enhancements don't inadvertently create wearable products. As mask wearing becomes increasingly normalized in various settings, breathability may ultimately determine whether people consistently wear masks properly—making it as functionally important as filtration efficiency.

Ready to optimize the breathability of your multi-layer cloth masks through systematic testing and design refinement? Contact our Business Director, Elaine, at elaine@fumaoclothing.com to discuss our breathability testing capabilities and design optimization expertise. We'll help you achieve the ideal balance between protection and comfort for your specific market needs.