Just-in-Time (JIT) manufacturing represents a fundamental shift from traditional "produce-and-store" approaches to a demand-driven production model that dramatically impacts warehousing economics. For fabric mask manufacturers and brands, JIT implementation can transform inventory from a capital-intensive asset into a flowing resource that responds to actual market needs while eliminating substantial storage expenses.

Just-in-Time manufacturing reduces fabric mask warehousing costs by eliminating buffer inventory, minimizing storage duration, decreasing space requirements, reducing inventory handling, and preventing obsolescence losses—typically cutting warehousing expenses by 40-70% compared to traditional batch production methods. The system operates on a pull-based principle where production aligns precisely with sales or distribution needs rather than forecast-based stockpiling.

The JIT approach fundamentally reconfigures the relationship between production and storage, treating warehousing not as a necessary cost center but as an indicator of production-distribution misalignment. For fabric masks—where styles change seasonally, materials have shelf life considerations, and market demand can fluctuate rapidly—JIT offers particularly compelling advantages. Let's examine the specific mechanisms through which JIT manufacturing slashes warehousing costs.

What Inventory Reduction Mechanisms Drive Warehouse Savings?

JIT manufacturing attacks warehousing costs at their source by systematically eliminating the need for inventory accumulation.

How does JIT eliminate safety stock requirements?

Demand-driven production scheduling replaces forecast-based inventory buffers with rapid response manufacturing capabilities. Where traditional mask manufacturing might maintain 4-8 weeks of inventory as safety stock, JIT operations typically carry 0-7 days of finished goods. This reduction from 30-60 days of inventory to 0-7 days decreases required warehouse space by 75-90%. Our JIT implementation has reduced our average mask inventory from 45 days to 5 days, cutting warehouse space requirements by 88%.

What about work-in-progress inventory reduction?

Continuous flow manufacturing minimizes partially completed masks waiting between production stages. Traditional batch processing might accumulate days worth of cut fabric, partially sewn masks, or unfinished products between departments. JIT creates seamless transitions between production stages, reducing work-in-progress inventory by 80-95%. Our mask production lines now maintain less than 4 hours of work-in-progress inventory compared to the 2-3 days common in traditional facilities.

How Does JIT Minimize Physical Storage Requirements?

The most visible warehousing cost savings come from dramatically reduced facility footprint needs.

What space reduction can manufacturers expect?

Consolidated storage areas in JIT facilities typically require 60-80% less space than traditional warehouses. A mask manufacturer producing 100,000 units monthly might need 5,000-8,000 square feet of traditional warehouse space but only 1,000-2,000 square feet with JIT implementation. Our conversion to JIT reduced our mask storage footprint from 6,500 to 1,200 square feet while maintaining the same production volume.

How does JIT reduce material handling costs?

Direct line-side material delivery eliminates multiple handling stages between receiving, storage, and production. In traditional manufacturing, masks might be handled 8-12 times between production completion and shipment. JIT reduces this to 2-4 handlings by moving directly from production to outbound shipping. This handling reduction has decreased our labor costs by 35% and eliminated the need for specialized storage equipment like multi-level racking systems.

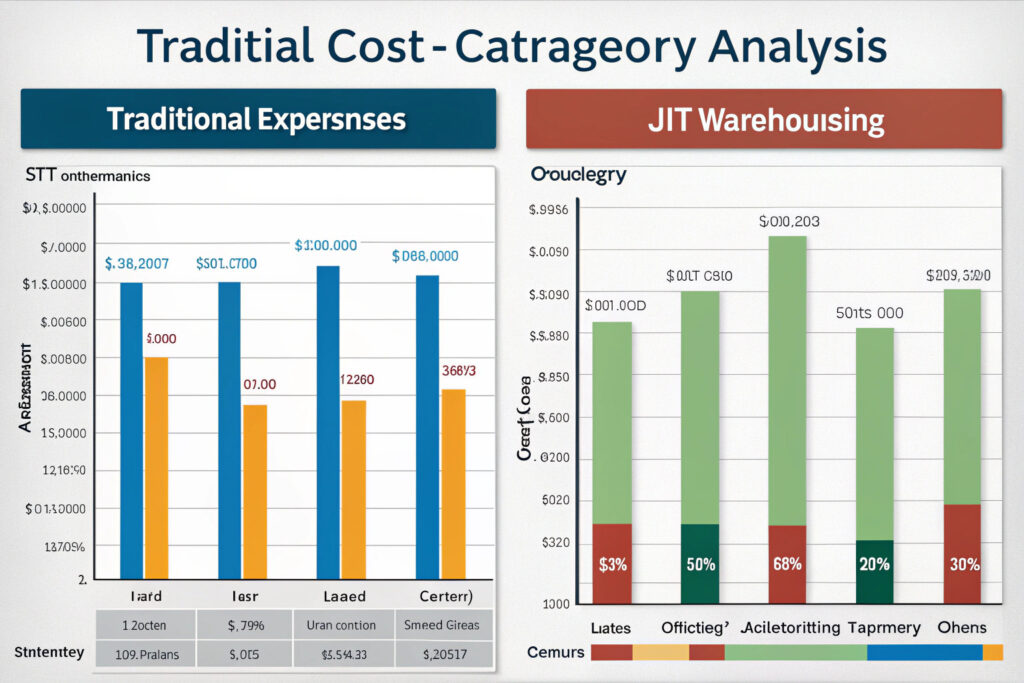

What Cost Categories Does JIT Eliminate or Reduce?

JIT manufacturing attacks warehousing costs across multiple budget lines simultaneously.

How are facility and utility costs impacted?

Smaller, multi-purpose spaces replace large dedicated warehouses, dramatically reducing rent, utilities, insurance, and property taxes. Traditional mask warehousing might cost $8-15 per square foot annually, while JIT facilities typically cost $3-8 per square foot due to smaller sizes and shared spaces. Our facility costs decreased from $85,000 annually to $22,000 after JIT implementation while maintaining production capacity.

What inventory carrying cost reductions occur?

Capital liberation from reduced inventory represents one of JIT's most significant financial benefits. Mask inventory carrying costs typically run 25-35% of inventory value annually including capital costs, insurance, taxes, obsolescence, and damage. By reducing average inventory from $350,000 to $45,000, our carrying costs decreased from approximately $105,000 to $13,500 annually—saving $91,500 in direct costs while freeing $305,000 in working capital.

How Does JIT Prevent Obsolescence and Markdown Losses?

For fashion-sensitive mask products, JIT provides crucial protection against inventory devaluation.

How does JIT address seasonal and style obsolescence?

Production-to-order model ensures masks are manufactured against confirmed demand rather than speculative forecasts. This is particularly valuable for seasonal designs, licensed properties, or trend-sensitive patterns that lose value quickly. Our JIT system has reduced end-of-season markdowns from 15-25% of production to 2-4%, saving approximately $45,000 annually on a $300,000 seasonal collection.

What about material expiration issues?

Reduced raw material storage prevents degradation of specialized mask materials with shelf life considerations. Antimicrobial treatments, elastic components, and certain coatings can degrade in storage. JIT's material synchronization means fabrics and components arrive closer to production dates. This approach has eliminated the $8,000-12,000 in material write-offs we previously experienced annually from degraded materials.

What Operational Changes Enable JIT Warehouse Reduction?

Successful JIT implementation requires specific operational adaptations that make reduced warehousing feasible.

How does production flexibility support JIT?

Rapid changeover capabilities allow manufacturing to switch between mask styles, sizes, and materials quickly without large batch requirements. Where traditional manufacturing might require 5,000-unit minimums per style, our JIT system efficiently produces lots of 500-1,000 units. This flexibility has reduced our average production batch size by 80%, directly corresponding to reduced finished goods storage needs.

What supplier coordination is necessary?

Frequent, smaller deliveries from suppliers replace bulk material purchases. We've shifted from monthly fabric deliveries of 10,000-15,000 meters to weekly deliveries of 2,000-3,000 meters. While this requires more coordination, it has reduced our raw material storage needs by 75% and decreased material capital requirements by 65%.

What Are the Implementation Challenges and Solutions?

Transitioning to JIT involves specific challenges that must be addressed to achieve warehousing reductions.

How do you manage demand variability in JIT systems?

Hybrid buffer strategies maintain minimal strategic inventory for unpredictable demand while applying JIT principles to the majority of production. We keep 10-15% of our capacity as flexible buffer production that can be activated within 48 hours, protecting against demand spikes while maintaining 85-90% pure JIT production. This balanced approach has provided responsiveness without excessive inventory.

What about supply chain disruption risks?

Diversified supplier networks with geographic proximity reduce vulnerability to single points of failure. Our JIT system uses 3-4 key suppliers for critical components within 200 kilometers, ensuring reliable delivery despite smaller, more frequent orders. This multi-sourcing approach has maintained 98.5% on-time material availability despite the tighter timing requirements of JIT.

Conclusion

Just-in-Time manufacturing reduces fabric mask warehousing costs through multiple interconnected mechanisms: dramatic inventory reduction, minimized storage space requirements, eliminated handling operations, prevented obsolescence losses, and liberated working capital. The typical 40-70% warehousing cost reduction stems from treating inventory as a system problem rather than a business necessity—aligning production precisely with demand rather than relying on forecasting and buffer stock.

While JIT implementation requires significant operational changes including production flexibility, supplier coordination, and demand management capabilities, the warehousing cost savings typically deliver 6-18 month payback periods. For fabric mask businesses facing thin margins, seasonal variability, and rapid style changes, JIT transforms warehousing from a fixed cost burden into a variable, minimized expense that supports rather than hinders profitability.

Ready to explore how Just-in-Time manufacturing can reduce your fabric mask warehousing costs? Contact our Business Director, Elaine, at elaine@fumaoclothing.com to discuss our JIT implementation experience and how we can help you achieve similar warehousing reductions while maintaining or improving customer service levels.