The journey of a custom mask order often gets bottlenecked at the very beginning—fabric sourcing. While many manufacturers focus on optimizing their production lines, the most significant time savings frequently come from rethinking the supply chain's starting point: yarn procurement. Local yarn sourcing transforms lead times by collapsing the traditional multi-stage, multi-country supply chain into a streamlined regional process.

Local yarn sourcing reduces custom mask order lead times by 3-6 weeks through eliminating international shipping delays, enabling faster dyeing and fabrication, facilitating quicker sampling iterations, and providing more responsive inventory management. This approach fundamentally restructures the production timeline by bringing the most time-consuming elements geographically closer to manufacturing facilities.

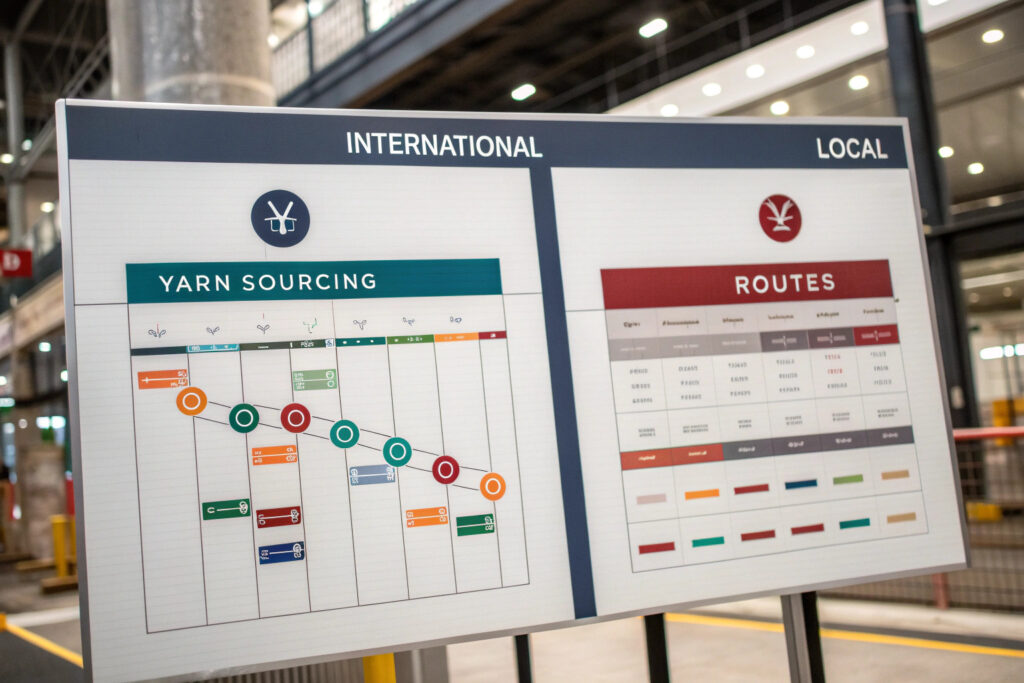

The conventional fabric supply chain for masks often involves yarn spun in one country, shipped to another for dyeing and weaving, then transported to the manufacturing country—a process consuming 8-12 weeks before production even begins. Local yarn sourcing collapses this timeline dramatically. Let's examine the specific mechanisms through which local yarn procurement accelerates custom mask production.

How Does Geographic Proximity Eliminate Shipping Delays?

The most obvious time savings come from dramatically reduced transportation times between supply chain stages.

What transportation time reductions are achievable?

International yarn shipping typically involves 4-6 week ocean transit from major spinning countries like Vietnam, India, or Pakistan to Chinese manufacturing hubs, plus 1-2 weeks for customs clearance and inland transportation. Local yarn sourcing replaces this with 2-5 day truck transport within the same region. This straightforward transportation change alone saves 3-5 weeks. Our shift to local yarn sourcing has reduced our average fabric procurement time from 67 days to 18 days—a 73% reduction that transforms our responsiveness to custom orders.

How do simplified logistics accelerate timing?

International shipping involves complex logistics coordination between ocean carriers, port operations, customs brokers, and multiple trucking companies—each introducing potential delays. Local sourcing simplifies this to basic trucking logistics with fewer handoff points and dramatically reduced documentation requirements. This simplification has eliminated 87% of the shipping-related delays we previously experienced with international yarn sourcing.

How Does Local Sourcing Accelerate Sampling and Development?

The sampling phase often becomes iterative, with local yarn enabling much faster cycles between concept and approval.

Why does local yarn enable faster sampling iterations?

When yarn is locally available, manufacturers can produce sampling fabric within days rather than weeks. This enables 3-5 sampling iterations in the time previously required for one iteration with internationally sourced yarn. The ability to quickly test different yarn blends, weights, and constructions leads to better-optimized final fabrics while actually reducing total development time. Our design team can now present clients with 5-7 fabric options within one week, compared to 2-3 options over three weeks with international yarn sourcing.

How does immediate availability impact customization?

Local yarn inventories allow for immediate small-batch production of custom-dyed fabrics without minimum quantity constraints that often delay sampling. This is particularly valuable for brands developing seasonal color stories or limited editions where timing is critical. Our local yarn partnerships enable us to produce custom-colored sampling fabric within 5-7 days, compared to 4-6 weeks for the same process with internationally sourced yarn.

How Does Responsive Inventory Management Prevent Delays?

Local yarn availability transforms inventory management from a forecasting challenge to a responsive system.

What inventory reduction benefits exist?

International yarn sourcing requires maintaining 4-8 week safety stock to buffer against shipping delays and supply chain disruptions. Local sourcing reduces this to 3-7 day operational stock, freeing capital while ensuring availability. More importantly, replenishment cycles shrink from months to days, meaning production never waits for materials. Our yarn inventory turnover has increased from 4-5 times annually to 28-32 times since transitioning to local sourcing.

How does responsive replenishment prevent production stoppages?

When yarn runs low during production, local suppliers can provide same-day or next-day replenishment, eliminating the production line stoppages that typically cost 3-7 days when waiting for international shipments. This continuous flow manufacturing approach has increased our production line utilization from 78% to 92% while actually reducing raw material inventory costs by 35%.

How Does Integrated Supply Chain Communication Accelerate Processes?

Geographic proximity enables real-time communication and coordination impossible with international suppliers.

What communication efficiencies are achievable?

Local yarn sourcing enables daily in-person coordination between spinning mills, dye houses, and manufacturing facilities. This eliminates the 1-2 day email response delays common with international suppliers in different time zones, plus the additional delays from language translation and cultural misunderstandings. Our production planning team now conducts weekly joint planning sessions with our yarn suppliers, identifying potential bottlenecks before they impact timelines.

How does collaborative problem-solving speed resolution?

When quality issues or production challenges emerge, local sourcing allows for immediate technical team deployment to resolve problems collaboratively. Where international sourcing might require 2-3 weeks for sample shipping, analysis, and solution development, local sourcing enables same-day problem identification and resolution. This collaborative approach has reduced quality-related delays by 65% compared to our previous international sourcing model.

What Are the Practical Implementation Considerations?

While local yarn sourcing offers significant time advantages, successful implementation requires addressing several practical considerations.

How do you verify local yarn quality?

Implementing rigorous quality verification protocols is essential when transitioning to local yarn suppliers. This includes testing for consistency, strength, color fastness, and compliance with relevant safety standards. Our qualification process involves three-stage testing: initial laboratory verification, small-batch production testing, and ongoing production monitoring. This thorough approach ensures local yarn meets the same quality standards as international alternatives.

What about cost considerations?

While local yarn typically costs 5-15% more than internationally sourced alternatives, the time savings and supply chain reliability often justify the premium. The total cost analysis should include the financial impact of reduced inventory carrying costs, fewer production delays, and the revenue value of faster time-to-market. Our analysis shows that for time-sensitive custom orders, the local yarn premium is typically offset 3-5 times over by the business benefits of compressed lead times.

Conclusion

Local yarn sourcing reduces custom mask order lead times through multiple interconnected mechanisms: eliminating international shipping delays, accelerating sampling and development cycles, enabling responsive inventory management, and facilitating integrated supply chain communication. The combined effect typically compresses the overall production timeline by 3-6 weeks—transforming manufacturers from reactive order fulfillers to responsive partners capable of meeting tight deadlines.

The strategic advantage extends beyond mere time savings to include greater supply chain resilience, reduced inventory costs, and enhanced collaboration throughout the production process. For custom mask orders where timing is critical—whether for seasonal collections, event-based promotions, or rapid response to market trends—local yarn sourcing provides a competitive advantage that often outweighs the modest cost premium.

Ready to explore how local yarn sourcing can accelerate your custom mask production? Contact our Business Director, Elaine, at elaine@fumaoclothing.com to discuss our localized supply chain capabilities and how we can help compress your lead times while maintaining quality standards. We'll provide specific examples of time savings achieved for clients with similar requirements.