When wearing a cloth face mask, few features impact performance and comfort as significantly as the nose wire. From better fit to fog prevention, this small detail has become a must-have in premium and functional mask lines.

A properly designed nose wire dramatically improves seal, stability, and comfort, especially for glasses wearers and active users. It enhances protection by reducing side gaps and improves user compliance by ensuring a tailored feel across different face shapes.

At ChinaClothMask, we integrate various nose wire options across 3D, pleated, and contour mask formats. Here’s what you need to know when sourcing cloth face coverings with this essential feature.

What Is the Primary Function of a Nose Wire?

The nose wire—or nose bridge strip—is a flexible insert sewn or glued into the top edge of a fabric mask. Its purpose is simple but vital: achieve a sealed fit around the bridge of the nose.

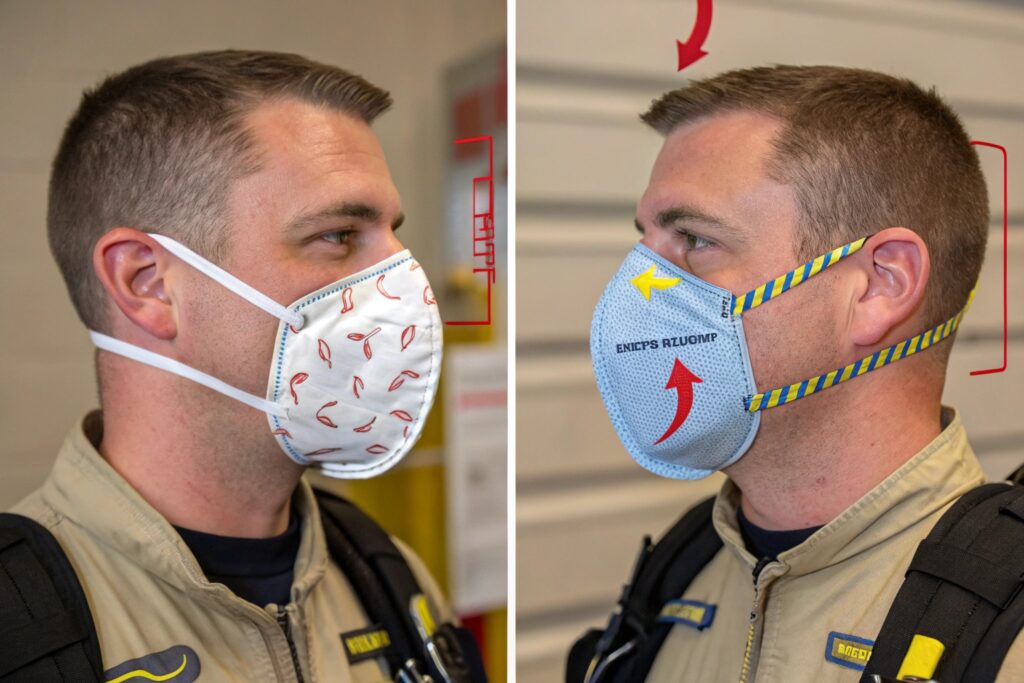

By minimizing the gap between the mask and skin, a nose wire helps prevent unfiltered air leakage and stabilizes the mask during movement. This seal is especially important for preventing droplet escape and external dust or pollen entry.

What Are the Typical Nose Wire Materials?

Most high-quality nose wires are made from aluminum strips (soft, rust-free, and shape-retaining), galvanized iron wire, or double-core plastic coated wires. Some designs include a foam backing for added comfort.

Can Nose Wires Be Removed or Replaced?

Yes. Some of our customers request removable nose wire slots. This is especially useful for washing longevity or replacement after damage. These can be added with a small fabric tunnel sewn inside the upper hem.

How Does Nose Wire Enhance Mask Performance?

A mask that fits poorly around the nose is ineffective at filtering inhaled or exhaled air. Even a triple-layer or filtered mask loses protection if airflow escapes from the top edge.

With a molded nose wire, airflow is redirected downward or through the mask body, maximizing filtration potential. It also keeps the mask from sliding, reducing the need for frequent hand adjustments.

Is Fogging Reduced for Glasses Wearers?

Absolutely. Nose wires reduce lens fogging by sealing the top of the mask and preventing upward airflow. This is especially useful in winter or indoor air-conditioned environments.

Does It Improve Fit for All Face Shapes?

Yes. Adjustable nose wires allow the same mask to fit narrow, wide, or high bridges. This versatility is especially important for bulk orders targeting broad demographics or mixed-gender users.

What Are the Design Options for Nose Wire Masks?

Not all fabric masks are created equal—and how the nose wire is integrated affects both form and function.

Nose wires can be stitched into contour seams, placed inside fabric tunnels, or fused via ultrasonic pressing in surgical-style pleated masks. Each format offers unique benefits for different industries or wear types.

Which Styles Work Best for Nose Wire Integration?

Contour and 3D masks offer the most seamless integration due to shaped seams. Pleated masks benefit from wide wires for adjustable coverage. Our most successful designs include:

- 3D poly-cotton masks with full-length nose wire

- Pleated cotton masks with 8cm aluminum inserts

- Duckbill-style masks with center-stitch nose tunnels

Can Branded Masks Include Nose Wires?

Yes. We regularly supply branded corporate masks with concealed wires, logo printing, and custom packaging for uniform distribution. MOQ starts at 1,000 pcs.

How Should Nose Wire Masks Be Packaged and Shipped?

Because of the bendable metal insert, nose wire masks require extra care during packing to avoid damage. Bent wires can distort the mask and reduce fit integrity.

Masks should be folded with wire positioned flat and reinforced with inner cartons or protective pouches. We recommend labeling boxes as “nose-wire masks” for careful handling during freight.

Is There an Added Cost for Nose Wire Features?

Adding a nose wire raises per-unit cost by $0.03–$0.08 depending on material. However, resale value, comfort feedback, and perceived quality increase significantly. Most of our U.S. and EU clients opt to include it as a standard.

What’s the Lead Time for Nose Wire Mask Orders?

Standard lead time is 12–18 days from sample approval. For bulk orders of 20,000+ units with custom features, allow 20–25 days including QC and packaging.

Conclusion

A nose wire is a small but crucial feature that transforms a cloth mask from average to exceptional. It improves fit, protects better, and enhances user experience—especially for glasses wearers and sensitive users. Whether you’re building a retail line, institutional order, or brand promo gift, adding a nose wire is a best-practice standard. At ChinaClothMask, we integrate durable, tested nose wire options in all formats—supported by low MOQ, custom options, and global fulfillment. Let us help you deliver comfort and protection, wire to wire.