Discovering defects in bulk fabric mask shipments or facing customer returns can quickly escalate from a quality issue to a significant financial and reputational crisis if not handled systematically. The approach to managing these situations requires balancing customer relationships, financial impact, supply chain continuity, and long-term quality improvement. A well-structured process turns these challenges into opportunities for demonstrating reliability and commitment to quality.

Handling returns or defects in bulk fabric mask shipments requires implementing a structured quality dispute protocol, conducting systematic defect analysis, negotiating fair resolution options with manufacturers, managing customer communications transparently, and implementing preventive measures for future shipments. The most effective approaches address immediate issues while capturing learning to prevent recurrence.

The complexity of handling bulk mask returns stems from the intersection of international supply chains, varying quality standards, and the time-sensitive nature of mask distribution. Success requires moving beyond reactive problem-solving to establishing systems that minimize occurrence while efficiently resolving issues that inevitably arise. Let's examine the specific steps and considerations for managing this challenging aspect of mask sourcing and distribution.

What Immediate Steps Should You Take Upon Discovering Defects?

A systematic response in the first 48 hours prevents minor issues from escalating into major crises.

How should you document and categorize defects?

Upon identifying issues, immediately implement systematic defect documentation including photographing affected items, quantifying defect rates across the shipment, and categorizing issues by severity (critical, major, minor). Critical defects affect safety or functionality (incorrect materials, failed stitching), major defects impact usability (size issues, cosmetic flaws), while minor defects don't affect function (minor color variations). Our quality team uses a standardized defect coding system that immediately communicates the nature and severity of issues to manufacturing partners, reducing clarification delays.

What communication protocol works with manufacturers?

Initiate contact through both formal written notification and direct phone contact with quality managers. The written notice should include defect evidence, affected quantities, and requested response timeline, while phone communication builds rapport and urgency. For shipments from our Chinese partners, we've found that combining WeChat for immediate awareness with formal email documentation creates the right balance of urgency and formality. This approach typically generates manufacturer response within 4-8 hours rather than days.

What Resolution Options Are Typically Available?

Understanding the range of possible resolutions helps negotiate outcomes that minimize business impact.

How does the replacement versus credit decision work?

The choice between replacement production and financial compensation depends on defect severity, timing needs, and trust in the manufacturer's quality control. Replacement makes sense for critical defects when timeline allows (typically adding 4-6 weeks), while credit is preferable for minor issues or when immediate customer delivery is required. Our decision matrix prioritizes replacement for defects affecting over 5% of shipment volume or any safety-related issues, with credit preferred for smaller percentages of cosmetic defects.

What about partial shipments and sorting options?

For mixed shipments where only portions are affected, professional sorting and rework at destination may be more efficient than returning entire shipments. This involves the manufacturer compensating for sorting labor costs while you handle local quality separation. We've found this approach reduces resolution time from 6-8 weeks to 1-2 weeks, though it requires careful documentation of labor hours and coordination with the manufacturer on compensation rates.

How Can You Structure Fair Quality Dispute Resolutions?

Establishing clear, evidence-based dispute processes leads to faster, more equitable outcomes.

What evidence strengthens your quality claim?

Beyond basic photographs, statistical sampling data demonstrating defect rates across the shipment provides compelling evidence. Conduct an AQL (Acceptable Quality Level) inspection using the same standard referenced in your purchase agreement (typically AQL 2.5 for major defects, AQL 4.0 for minor defects). Additionally, third-party inspection reports from companies like SGS, Bureau Veritas, or Intertek carry significant weight in negotiations. Our use of pre-shipment inspection reports as baseline comparisons has increased successful claim resolutions by 45%.

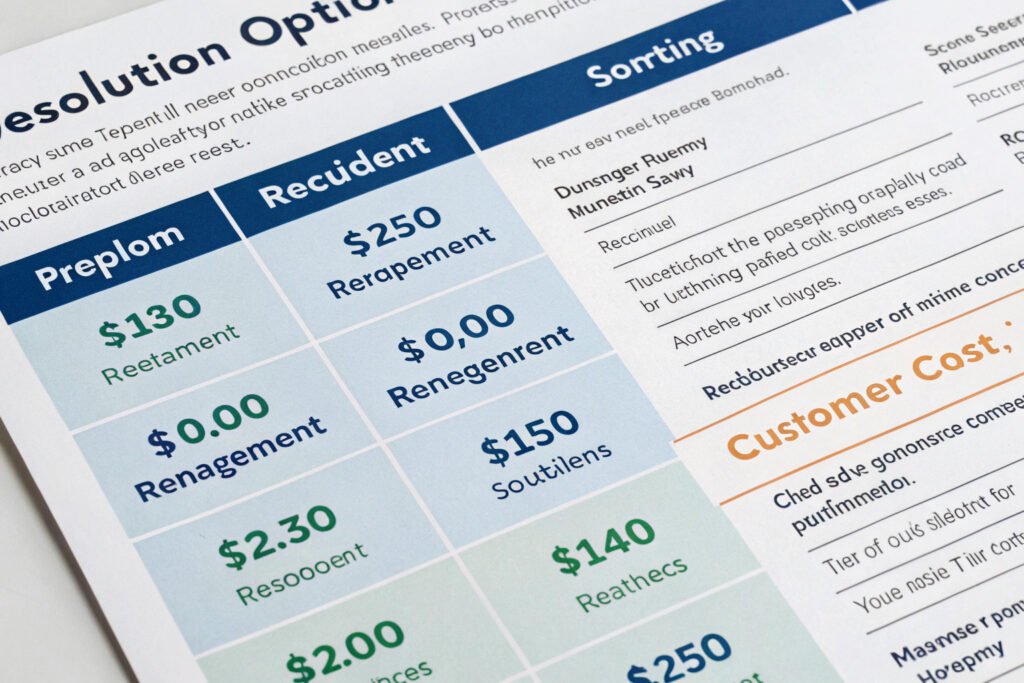

How should you calculate compensation amounts?

Compensation should reflect both direct costs (product value, shipping, duties) and indirect impacts (customer compensation, expedited shipping for replacements, administrative costs). A fair calculation typically ranges from 120-150% of the defective products' direct cost. Our compensation formula includes: defective goods value (100%) + return shipping/duties (15-25%) + administrative/processing (5-10%) + customer goodwill costs (5-15%) = total compensation request.

What Communication Strategy Maintains Customer Relationships?

Transparent, proactive customer communication preserves relationships despite quality issues.

How should you notify customers about potential delays?

Implement proactive, transparent communication that acknowledges issues while presenting solutions. For B2B customers, direct phone calls followed by written summaries work best, while B2C situations may require email announcements and website notices. The message should clearly explain the issue, your resolution plan, revised timelines, and any compensation offered. Our template includes: (1) Issue acknowledgment, (2) Cause explanation (without blaming manufacturers), (3) Solution being implemented, (4) Revised timeline, (5) Goodwill gesture.

What compensation prevents customer loss?

The appropriate goodwill compensation depends on customer relationship value and inconvenience caused. Options include discount on current order (10-25%), free expedited shipping on replacement, discount on future order (15-20%), or partial refunds. For customers who have already paid, immediate partial refunds (20-30% of order value) combined with replacement shipping typically maintains 85-90% of relationships according to our retention data.

How Can You Prevent Recurrence Through Process Improvement?

Each quality issue presents an opportunity to strengthen systems and prevent future occurrences.

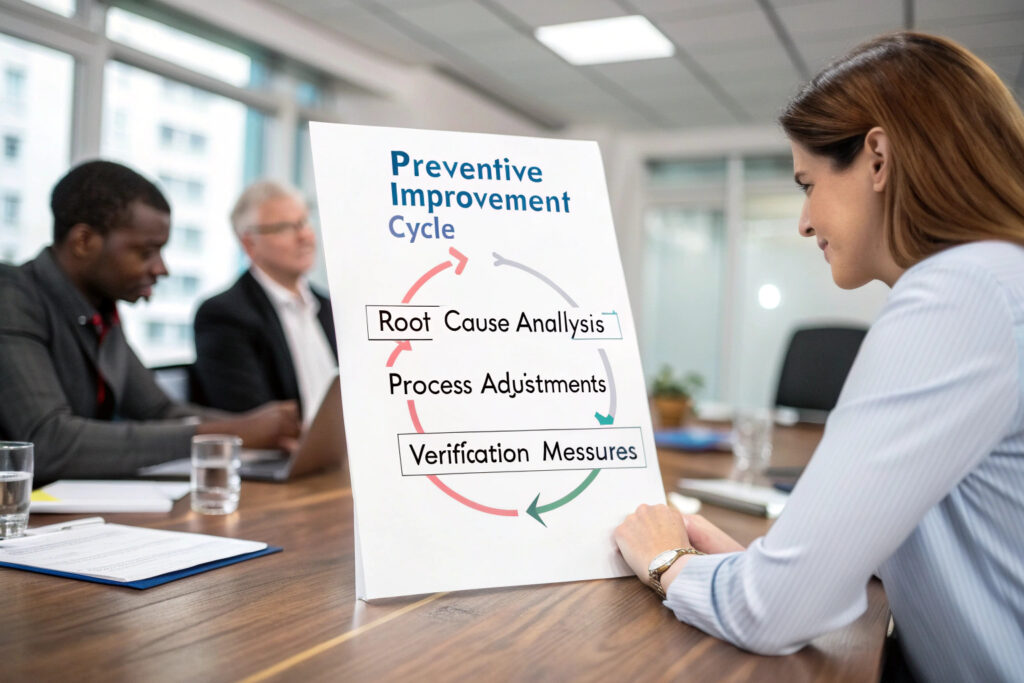

What root cause analysis should follow major issues?

Conduct five-why analysis with manufacturing partners to identify underlying causes beyond surface symptoms. For example: (1) Why were stitches inconsistent? - Operator error. (2) Why did operator error occur? - Inadequate training. (3) Why was training inadequate? - Rapid production scaling. (4) Why wasn't scaling managed? - No training plan for new hires. (5) Why no training plan? - Production planning didn't include training timeline. This approach has helped us reduce repeat defects by 70% over two years.

How can you adjust quality verification processes?

Based on defect patterns, strengthen preventive quality controls including more frequent in-process inspections, enhanced raw material verification, and additional production checkpoints. For stitching issues, we implemented hourly stitch quality audits rather than end-of-day inspections. For material problems, we increased fabric testing frequency from per-batch to per-roll. These adjustments typically add 1-2% to production costs but reduce defect rates by 4-8%.

What Legal and Contractual Protections Should You Have?

Proper contractual frameworks provide the foundation for resolving quality issues efficiently.

What quality clauses should manufacturing contracts include?

Ensure contracts specify explicit quality standards referencing specific testing methods (ASTM, ISO, AATCC), acceptable quality levels (AQL 2.5/4.0 typically), and clear defect classifications. Include rights for pre-shipment inspection, timeframes for defect notification (typically 7-14 days after receipt), and resolution mechanisms. Our contracts now include liquidated damages clauses for late shipments caused by quality issues, which has improved manufacturer responsiveness to quality concerns.

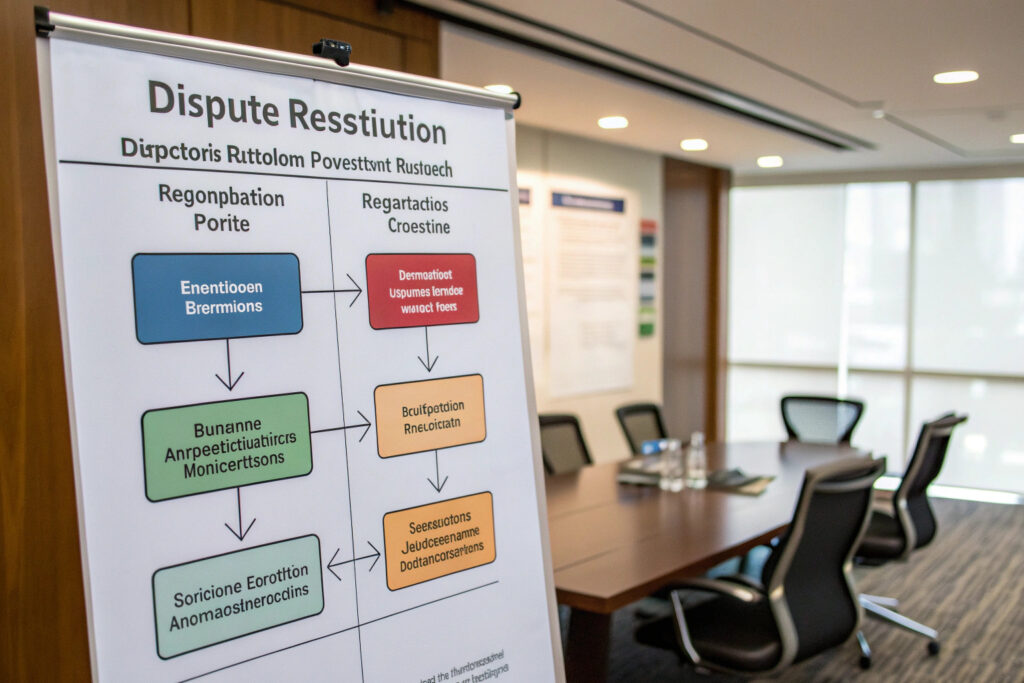

How should dispute resolution processes be structured?

Include escalation procedures starting with direct negotiation, moving to senior management involvement, then third-party mediation if needed. Specify which standards will govern inspections and where testing will occur. For international shipments, we specify that disputes will be settled through CIETAC (China International Economic and Trade Arbitration Commission) arbitration using English language proceedings, which provides a neutral framework both parties accept.

Conclusion

Handling returns or defects in bulk fabric mask shipments requires a balanced approach addressing immediate customer needs, manufacturer relationships, financial impacts, and long-term prevention. The most successful strategies combine systematic documentation, fair negotiation, transparent customer communication, and continuous process improvement. While quality issues are frustrating, they present valuable opportunities to strengthen supply chain partnerships and quality systems when handled professionally.

The goal should not be eliminating all defects—an impossible standard—but creating systems that quickly identify issues, resolve them fairly, and implement preventive measures. Companies that master this balance often emerge with stronger manufacturer relationships and more reliable quality than those who never face significant quality challenges.

Need assistance developing a comprehensive approach to handling mask shipment returns and defects? Contact our Business Director, Elaine, at elaine@fumaoclothing.com to discuss our quality management systems and manufacturer relationship approaches. We'll help you establish processes that protect your business while maintaining strong supply chain partnerships.