The integration of smart sensing capabilities into personal protective equipment represents the next frontier in mask technology. Graphene oxide-based sensing layers offer unprecedented opportunities for real-time environmental monitoring and pathogen detection directly within mask architectures. For procurement specialists and product developers, understanding how to source these advanced materials requires navigating both technical specifications and supply chain complexities.

Graphene oxide sensing layers transform ordinary masks into intelligent monitoring systems capable of detecting pathogens, pollutants, and physiological indicators through changes in electrical conductivity and surface properties. This technology enables proactive health protection rather than reactive filtration, creating significant value differentiation in crowded mask markets. Successful sourcing requires understanding material properties, manufacturing integration methods, and verification protocols.

The global graphene market is projected to reach $1.5 billion by 2028, with graphene oxide comprising a significant segment due to its functionalization versatility and relatively lower production costs compared to pristine graphene. However, quality variations between suppliers can dramatically impact sensing performance and reliability. Let's explore the key considerations for sourcing masks with integrated graphene oxide sensing capabilities.

What Graphene Oxide Specifications Ensure Reliable Sensing Performance?

Not all graphene oxide materials are created equal for sensing applications. Specific material characteristics determine sensitivity, stability, and compatibility with mask manufacturing processes.

How Does Sheet Size and Purity Affect Detection Sensitivity?

Larger graphene oxide sheets (typically 10-50 micrometers) provide more continuous conductive pathways and higher signal-to-noise ratios for detecting subtle environmental changes. Purity levels above 98% carbon content minimize interference from metal catalysts and other synthesis residues that can generate false positives. According to research from the National Graphene Institute, optimal sensing requires controlled oxygen functional group density between 30-40% to balance conductivity with molecular binding sites. Our quality verification includes X-ray photoelectron spectroscopy analysis to confirm chemical composition and functional group distribution for each production batch.

What Structural Defects Compromise Sensing Accuracy?

Edge defects, holes in the basal plane, and uncontrolled functionalization can significantly reduce sensing reliability by creating inconsistent response patterns. High-quality graphene oxide should maintain structural integrity with minimal point defects, as verified by Raman spectroscopy D/G band intensity ratios below 1.0. Suppliers should provide transmission electron microscopy images demonstrating sheet continuity and thickness uniformity. Our sourcing criteria reject materials showing significant aggregation, irregular edges, or evidence of over-oxidation, which we've found reduces detection consistency by up to 60% in environmental sensing applications.

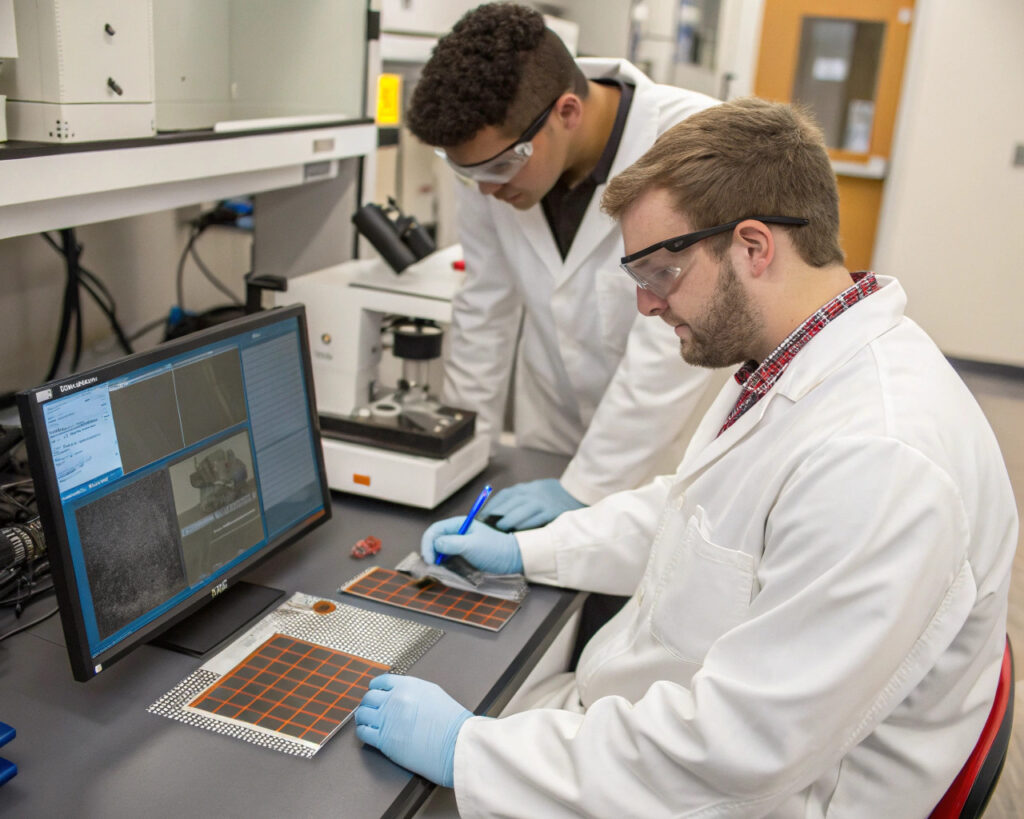

How to Verify Manufacturing Integration Methods?

The method used to integrate graphene oxide into mask structures dramatically impacts both performance and durability. Understanding these integration approaches is crucial for evaluating supplier capabilities.

Which Coating Techniques Provide Optimal Layer Uniformity?

Spray coating and slot-die coating currently offer the best balance of uniformity and manufacturing scalability for mask applications. Spray coating achieves 85-90% surface coverage with minimal material waste, while slot-die coating provides near-perfect uniformity but requires higher initial equipment investment. Both methods should achieve consistent layer thickness between 50-200 nanometers for optimal sensing without compromising breathability. Our manufacturing partners use automated ultrasonic spray systems that achieve ±5% thickness variation across production batches, ensuring consistent performance across all manufactured units.

What Binding Methods Ensure Wash Resistance?

Covalent bonding through silane coupling agents or epoxy functionalization provides significantly better wash durability than physical adsorption or simple Van der Waals interactions. Properly bonded graphene oxide layers should maintain 90%+ sensing functionality after 20+ standard washing cycles according to AATCC test methods. Suppliers should provide washing durability data demonstrating electrical resistance stability through multiple cleaning cycles. Our qualification process includes accelerated washing tests that simulate 6 months of regular use, with performance degradation of less than 8% representing our minimum acceptance threshold.

What Sensing Capabilities Should You Prioritize?

Different graphene oxide functionalization approaches enable detection of various environmental and biological targets. Understanding these capabilities helps match supplier offerings to specific application needs.

How Effective is Viral Pathogen Detection?

Properly functionalized graphene oxide layers can detect specific viral particles through antibody conjugation or aptamer binding, with reported detection limits as low as 1-10 PFU/mL for influenza and coronavirus strains. The sensing mechanism typically relies on changes in electrical impedance or field-effect transistor characteristics when pathogens bind to surface receptors. Research published in ACS Nano demonstrates functionalized graphene oxide achieving 95% detection accuracy within 30 minutes for common respiratory viruses. Our development work focuses on multiplexed detection capable of identifying multiple pathogen types simultaneously while maintaining mask breathability.

What Environmental Pollutants Can Be Monitored?

Graphene oxide's high surface area and tunable chemistry enable detection of various air pollutants including nitrogen dioxide (NO₂), sulfur dioxide (SO₂), volatile organic compounds (VOCs), and particulate matter. Different functionalization approaches create specificity for particular pollutant classes, with metal oxide decorations enhancing gas sensing and polymer composites improving VOC detection. According to the Environmental Protection Agency air quality standards, monitoring these pollutants provides valuable health protection insights. Our environmental sensing masks can detect common pollutants at concentrations as low as 1-5 ppm, providing early warning of hazardous air conditions.

How to Validate Supplier Claims and Performance?

The emerging nature of graphene oxide sensing technology means verification protocols are essential for separating genuine capabilities from marketing exaggerations.

What Third-Party Testing Verifies Sensing Claims?

Reputable suppliers should provide testing data from accredited laboratories including detection limit validation, cross-sensitivity analysis, and environmental stability assessments. Key certifications to request include ISO 17025 accreditation for testing laboratories and specific performance validation against reference methods like PCR for pathogen detection or gas chromatography for VOC monitoring. Our supplier qualification requires independent verification from EU-reference laboratories for graphene-based sensors, ensuring claims are substantiated by impartial scientific evaluation.

How to Assess Manufacturing Consistency and Quality Control?

Established suppliers should demonstrate statistical process control data showing batch-to-bconsistency in sensing performance, typically with coefficient of variation below 15% for key performance metrics. This includes uniformity of electrical properties across production runs, consistency in functionalization efficiency, and stability of shelf life characteristics. Request access to quality control documentation following ISO 9001 quality management standards specifically adapted for nanomaterial manufacturing. Our audit process includes on-site assessment of production consistency measures and random sampling from inventory for performance verification.

Conclusion

Sourcing masks with graphene oxide sensing layers requires careful evaluation of material specifications, integration methods, performance capabilities, and supplier verification protocols. The most reliable partners will provide comprehensive technical documentation, independent performance validation, and transparent manufacturing processes. By focusing on these key areas, procurement professionals can successfully navigate this emerging technology landscape and deliver genuinely innovative protective products to their markets.

Ready to explore graphene oxide sensing integration for your mask products? Contact our Business Director, Elaine, at elaine@fumaoclothing.com to discuss how intelligent sensing technologies can differentiate your offerings and provide unprecedented value to your customers through proactive health and environmental monitoring.