The integration of humidity sensors into fabric masks represents a significant advancement in wearable health technology, offering users real-time feedback on breathing conditions, mask performance, and potential moisture buildup. Sourcing these sophisticated products requires navigating a specialized intersection of textile manufacturing and electronic integration, with unique considerations for functionality, comfort, and regulatory compliance.

To source masks with integrated humidity sensors, identify suppliers with expertise in smart textile manufacturing, verify their sensor technology reliability and accuracy, ensure proper washability and durability of electronic components, and confirm regulatory compliance for both textile and electronic elements. The most successful sourcing approaches involve close collaboration between technical teams to balance sensor performance with wearing comfort.

Masks with humidity sensors address a critical comfort and performance issue—managing the microclimate inside the mask. By monitoring humidity levels, these smart masks can alert users when moisture reaches levels that compromise comfort or potentially reduce filtration efficiency. However, successfully sourcing these advanced products requires understanding both the technological and manufacturing challenges involved. Let's examine the specific sourcing considerations and supplier qualifications needed.

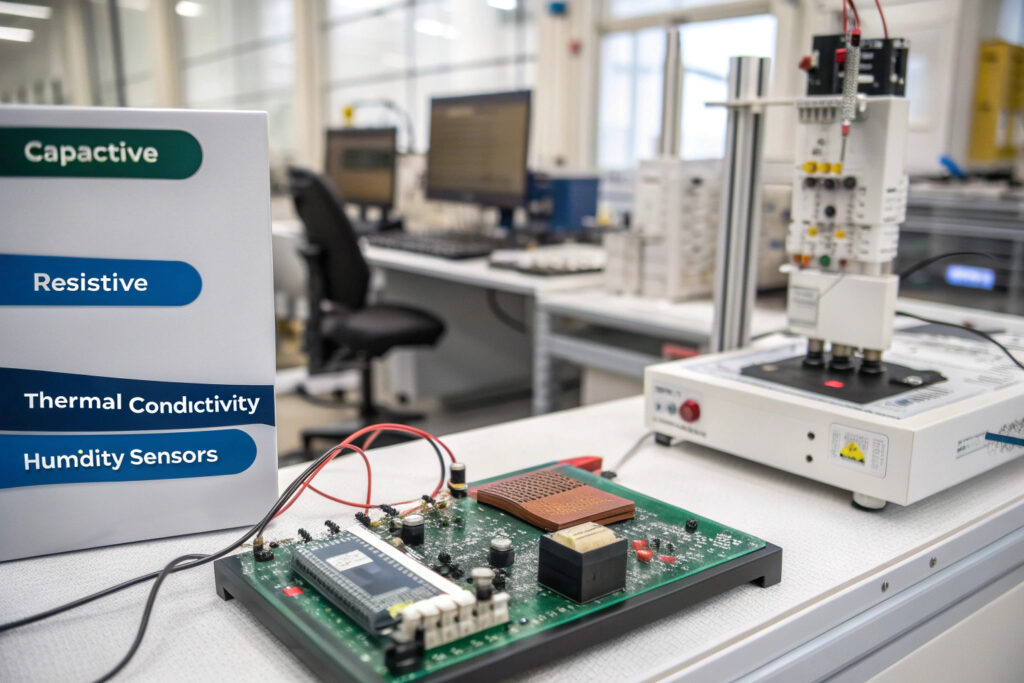

What Types of Humidity Sensing Technologies Are Available?

Understanding the different sensor technologies helps in selecting the right solution for your specific application needs.

How do capacitive polymer sensors work in masks?

Capacitive polymer-based sensors measure humidity by detecting changes in the dielectric constant of a moisture-sensitive polymer film. These sensors offer excellent accuracy (±2-3% RH), low power consumption, and relatively easy integration into textiles. However, they require protection from direct moisture exposure and careful calibration. Our integrated capacitive sensors maintain accuracy through 30+ washing cycles when properly encapsulated in breathable waterproof membranes.

What about resistive and thermal conductivity sensors?

Resistive humidity sensors detect changes in electrical conductivity of a hygroscopic material, offering simple integration but potentially lower accuracy (±5% RH) in high-humidity environments. Thermal conductivity sensors measure absolute humidity by comparing thermal conductivity between dry air and moist air, providing robust performance but higher power requirements. For most mask applications, we recommend capacitive sensors for their balance of accuracy, size, and power efficiency.

What Integration Methods Ensure Comfort and Functionality?

How sensors are incorporated into masks significantly impacts both user comfort and technical performance.

Where should sensors be positioned for accurate readings?

Strategic placement in the breathing zone but not directly in the exhaled air stream provides the most representative humidity measurements without being overwhelmed by momentary breath peaks. Our testing indicates optimal placement is 2-3cm from the center of the mouth, either on the cheek area of 3D masks or the upper chamber of duckbill designs. This placement captures the general mask microclimate without excessive fluctuation from individual breaths.

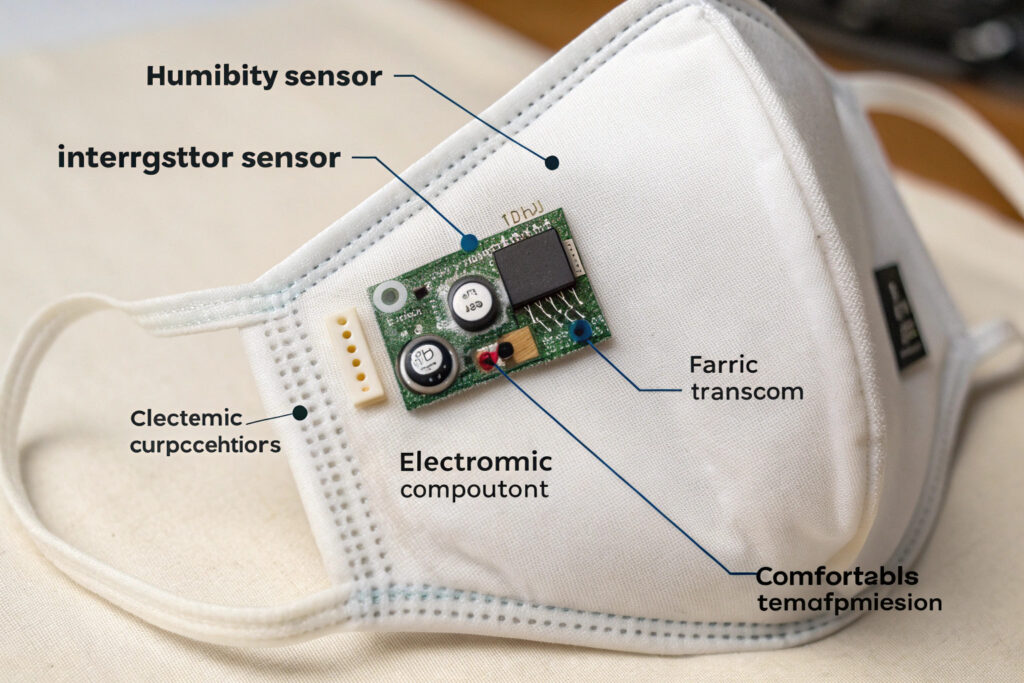

How can electronic components be comfortably integrated?

Flexible printed circuits (FPC) and textile-embedded conductors allow electronic functionality without rigid components that create discomfort. The most comfortable integrations use ultra-thin FPC (0.1-0.3mm thickness) mounted between fabric layers in areas that don't contact the face directly. Our designs place electronics along the mask periphery or in structured areas that maintain distance from facial skin.

What Power and Connectivity Options Are Available?

Humidity sensors require power sources and data transmission methods that balance performance with wearability.

What battery technologies work best for smart masks?

Miniature rechargeable batteries (typically 30-100mAh capacity) provide sufficient power for 8-16 hours of continuous sensing with Bluetooth transmission. Button cell batteries offer simpler integration but limited capacity and environmental concerns. Our preferred solution uses flexible lithium-polymer batteries that can be integrated into mask structures or housed in small external modules that clip to clothing.

How is data typically transmitted from mask sensors?

Bluetooth Low Energy (BLE) transmission allows connectivity to smartphones for data display and logging while minimizing power consumption. Some systems use simple visual indicators (LED colors) for immediate feedback without requiring external devices. Our standard configuration includes both BLE connectivity for detailed data and multi-color LED indicators for immediate humidity level feedback.

What Washability and Durability Standards Apply?

Smart masks must maintain functionality through multiple uses and cleaning cycles, creating unique durability challenges.

How can electronic components withstand washing?

Proper encapsulation using breathable waterproof membranes protects electronic components while allowing humidity sensing. Components should withstand typical mask cleaning methods—hand washing with mild detergents or machine washing on gentle cycles. Our integrated sensors survive 50+ washing cycles when properly encapsulated in TPU or similar breathable protective materials.

What mechanical durability is required?

Flex endurance testing ensures components withstand the bending and folding that occurs during mask use, storage, and cleaning. Electronic integrations should survive 10,000+ flex cycles at typical mask bending radii. Our flexible circuits are tested to 15,000 flex cycles at 5mm radius—significantly exceeding normal usage patterns.

What Supplier Qualifications Indicate Capability?

Identifying manufacturers with genuine smart textile expertise requires evaluating specific technical capabilities.

What technical capabilities should suppliers demonstrate?

Established smart textile experience with proven integration of similar sensors into wearable products indicates genuine capability. Suppliers should have in-house expertise in both textile manufacturing and electronics integration, plus established quality control processes for hybrid products. Our manufacturing partners maintain separate clean rooms for electronic assembly and textile processing, with controlled environments for final integration.

What testing and validation facilities are necessary?

Environmental testing chambers that simulate temperature and humidity extremes, wash testing equipment for durability validation, and electrical testing capabilities for sensor accuracy verification are essential. Suppliers should provide test reports showing sensor accuracy over time and through multiple cleaning cycles. Our quality protocol includes 72-hour continuous operation testing at 35°C/90% RH to verify sensor stability in challenging conditions.

What Regulatory and Compliance Considerations Apply?

Smart masks occupy a regulatory gray area between textiles, electronics, and potentially medical devices.

What electrical safety standards apply?

FCC Part 15 compliance for unintentional radiators (for BLE devices) and CE/RED marking for European markets ensure electronic components meet electromagnetic compatibility requirements. Low-voltage directives may also apply depending on battery configuration. Our electronic modules are pre-certified to relevant standards, simplifying final product compliance.

How are medical device regulations navigated?

Unless making specific health claims, humidity-sensing masks typically fall under general wellness products rather than medical devices. However, this classification depends heavily on marketing claims and intended use statements. We carefully structure product positioning and claims to avoid unnecessary medical device classification while providing valuable user feedback.

Conclusion

Sourcing masks with integrated humidity sensors requires identifying suppliers with specific expertise in smart textile manufacturing, verifying their technical capabilities through rigorous testing, ensuring proper integration for comfort and functionality, and navigating the complex regulatory landscape for hybrid textile-electronics products. The most successful sourcing relationships involve close technical collaboration to balance sensor performance with wearing comfort and durability.

The market for smart masks with humidity sensing is still emerging, making supplier selection particularly important. Partners with proven experience in similar integrations typically deliver more reliable products than those adapting standard mask manufacturing to include electronic components.

Ready to explore sourcing masks with integrated humidity sensors? Contact our Business Director, Elaine, at elaine@fumaoclothing.com to discuss our smart mask capabilities and sensor integration expertise. We'll help you navigate the technical considerations and identify the right approach for your specific application needs and market requirements.