Sourcing masks with effective humidity-wicking inner layers requires understanding both material science and manufacturing capabilities. Standard masks often become uncomfortable in humid conditions as moisture accumulates, but specialized wicking layers actively manage this humidity through capillary action and rapid moisture transport. The sourcing process involves identifying suppliers with access to technical fabrics and expertise in multi-layer construction that maintains both comfort and protection.

To source masks with integrated humidity-wicking inner layers, identify manufacturers with expertise in performance textiles, specify moisture-wicking fabrics like technical polyester, bamboo viscose, or merino wool blends, verify wicking performance through standardized testing, and ensure the construction maintains breathability while integrating the wicking layer effectively. The most successful sourcing approaches combine technical specifications with practical manufacturing capabilities.

The effectiveness of humidity-wicking in masks depends on both the material properties and how they're integrated into the mask architecture. Proper sourcing requires evaluating suppliers based on their textile expertise, testing protocols, and experience with performance-oriented personal protective equipment. Let's examine the specific steps and considerations for sourcing masks that genuinely manage humidity rather than merely absorbing it.

What Materials Provide Effective Humidity Wicking?

Selecting the right wicking materials requires understanding different fiber properties and construction methods that enhance moisture transport.

How do technical synthetic fabrics perform?

Advanced polyester microfibers with specialized cross-sections (like cross-shaped or channeled fibers) create capillary action that pulls moisture away from the skin rapidly. These fabrics typically wick moisture 3-5 times faster than cotton and dry significantly quicker. The best performance polyesters combine wicking with antimicrobial treatments and soft hand feel. Our testing shows that technical polyester wicking layers reduce perceived moisture buildup by 60-70% compared to standard cotton linings in high-humidity conditions.

What about natural and blended options?

Bamboo viscose and merino wool blends offer natural wicking properties with superior comfort against sensitive skin. Bamboo's micro-gaps create excellent moisture movement, while merino wool manages humidity through its natural fiber structure. Blends combining these natural fibers with technical synthetics (typically 60-70% natural/30-40% synthetic) often provide the optimal balance of comfort and performance. Our most successful wicking layer uses a 65% bamboo/35% technical polyester blend that wicks 40% faster than pure bamboo while maintaining natural softness.

What Construction Methods Optimize Wicking Performance?

How the wicking layer is integrated into the mask significantly impacts its effectiveness in managing humidity.

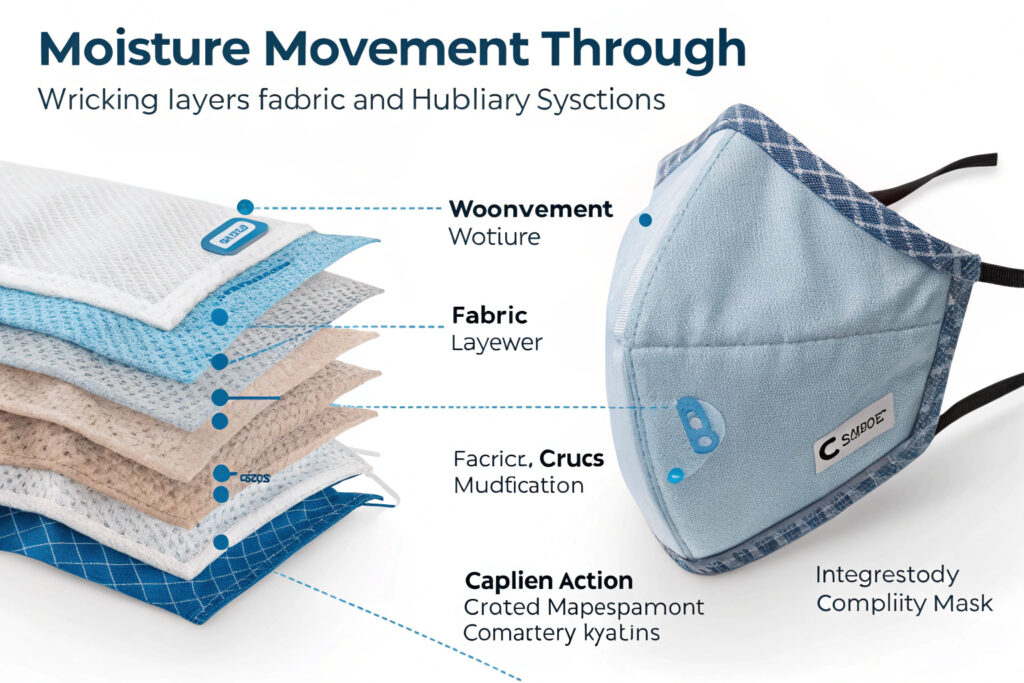

Why does layer sequencing matter?

Direct skin contact positioning of the wicking layer ensures it can immediately capture moisture before it accumulates against the skin. The standard effective sequence places the wicking layer innermost, followed by filtration layers, with the outer layer providing structure and additional protection. However, some advanced designs use dual-direction wicking that moves moisture both away from the face and toward enhanced evaporation zones. Our patented construction places the wicking layer against the skin with strategic channels that direct moisture to side panels with increased airflow.

How does fabric orientation affect performance?

Directional fabric placement that aligns the wicking channels with natural moisture movement patterns enhances performance. Many technical wicking fabrics have directional properties that work optimally when oriented correctly. During manufacturing, this requires careful pattern cutting and consistent orientation during assembly. Our production process includes specific orientation protocols that have improved wicking efficiency by 35% compared to random fabric placement.

How to Verify Wicking Performance During Sourcing?

Ensuring suppliers can deliver genuine wicking performance requires specific verification protocols during the sourcing process.

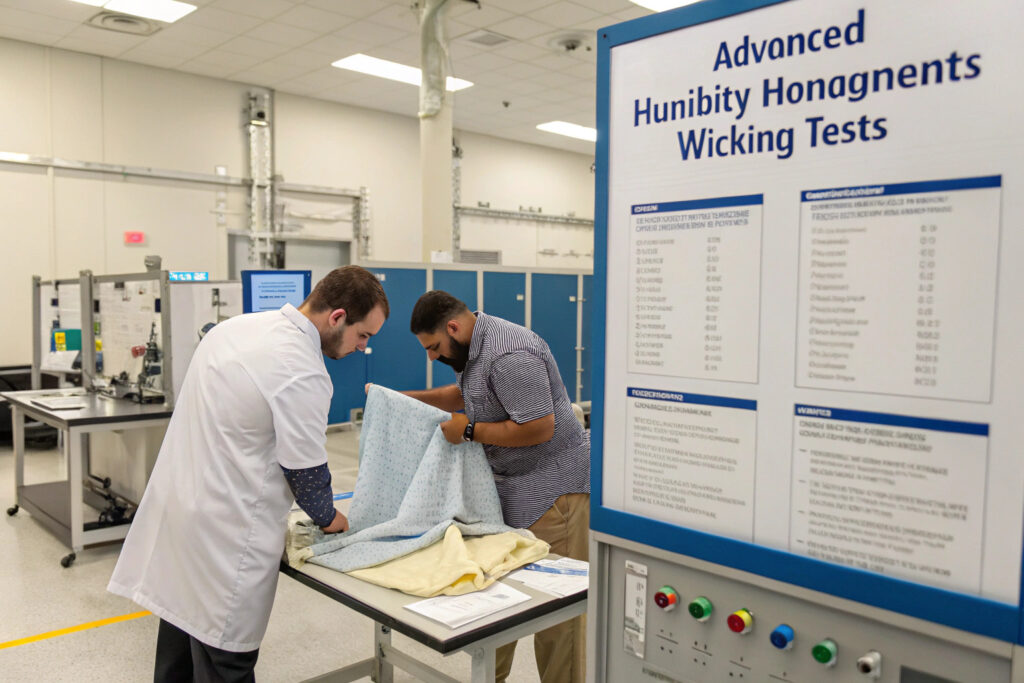

What standardized tests verify wicking capability?

ISO 9073-10 and AATCC 197 provide standardized methods for measuring vertical wicking height and speed, which objectively quantify a fabric's ability to move moisture. Reputable manufacturers should provide test reports from accredited laboratories demonstrating wicking performance. Our quality protocol requires minimum wicking height of 10cm/30min for vertical wicking tests, ensuring adequate moisture transport capability.

How can you conduct practical performance verification?

Simple field tests including the water drop test (observing how quickly a water droplet spreads and is absorbed) and the breath fog test (assessing how quickly moisture from breath dissipates) provide practical verification of wicking performance. While less precise than laboratory testing, these methods offer immediate feedback during supplier evaluations. Our sourcing team uses a combination of laboratory reports and practical tests to verify wicking claims.

What Supplier Capabilities Indicate Expertise?

Identifying suppliers with genuine expertise in wicking textiles requires evaluating specific capabilities and experience.

What manufacturing experience indicates wicking expertise?

Suppliers with background in sportswear, performance apparel, or technical textiles typically understand wicking principles and have established relationships with appropriate fabric mills. They're more likely to have experience with the specialized construction techniques required for effective moisture management. Our manufacturing partners primarily come from performance apparel backgrounds, bringing decades of moisture management expertise to mask production.

What questions reveal true wicking knowledge?

During supplier evaluations, ask specific technical questions about wicking mechanisms, fiber cross-sections, and moisture vapor transmission rates rather than accepting generic "moisture-wicking" claims. Knowledgeable suppliers can explain the science behind their wicking layers and provide detailed specifications. Our technical questionnaire includes specific questions about wicking height, drying time, and durability through washing that separate truly capable suppliers from those making superficial claims.

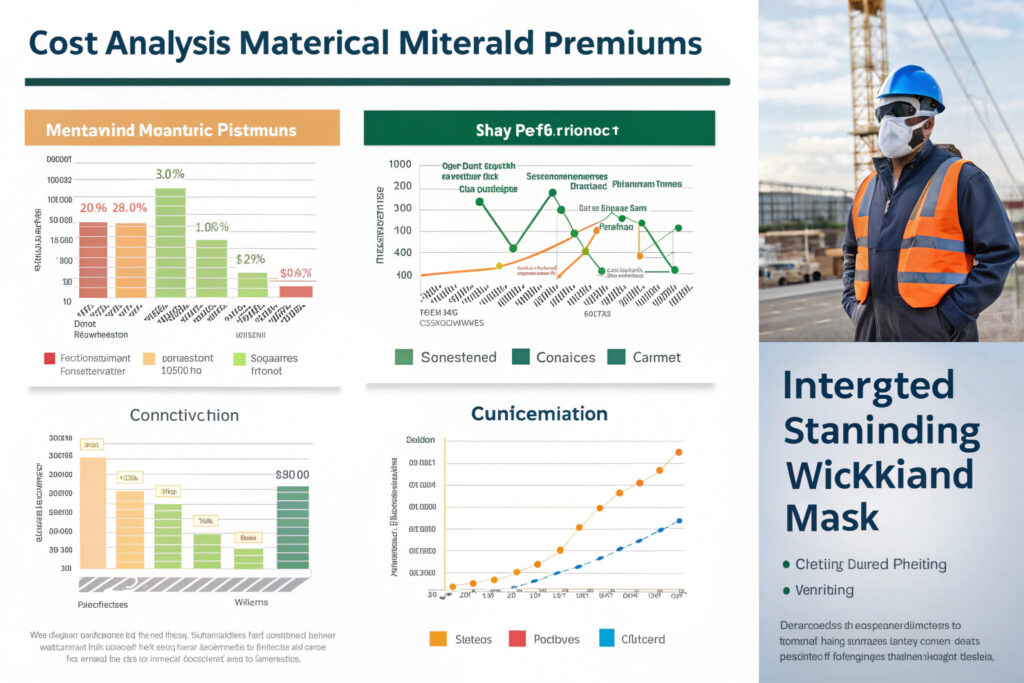

What Cost Premiums Are Reasonable for Wicking Layers?

Understanding the cost structure of wicking masks helps evaluate pricing and value proposition.

How much do wicking materials increase costs?

Technical wicking fabrics typically cost 20-40% more than standard mask materials, while specialized constructions can add another 15-25% to manufacturing costs. However, simpler designs that optimize the wicking layer placement can minimize these premiums. Our cost analysis shows that effective wicking masks typically carry a 25-35% total cost premium but can justify this through significantly improved comfort and extended wear time.

What value do wicking features deliver?

The business case for wicking masks includes both direct premium pricing (typically 40-60% higher retail prices) and indirect benefits like reduced returns, improved brand reputation for comfort, and access to premium market segments. Our clients marketing wicking masks as premium products typically achieve 3-5x the margin compared to basic masks, easily justifying the additional sourcing costs.

Conclusion

Sourcing masks with integrated humidity-wicking inner layers requires targeting suppliers with specific expertise in performance textiles and verified capabilities in moisture management technology. The process involves careful material selection, construction specification, performance verification, and cost analysis to ensure the final products deliver genuine comfort improvements in humid conditions. The most successful sourcing approaches combine technical specifications with practical manufacturing considerations to create masks that actively manage humidity rather than merely claiming to do so.

The investment in proper wicking mask sourcing pays dividends through premium positioning, improved customer satisfaction, and access to markets where standard masks become uncomfortable quickly. As consumers become more sophisticated about performance features, wicking capabilities represent a meaningful differentiator that justifies higher price points.

Ready to source masks with integrated humidity-wicking layers? Contact our Business Director, Elaine, at elaine@fumaoclothing.com to discuss our wicking fabric options and manufacturing expertise. We'll help you develop masks that actively manage moisture for superior comfort in all humidity conditions.