The growing global concern over air quality has expanded beyond particulate matter to include gaseous pollutants like ozone (O₃), a reactive gas that poses significant respiratory risks at ground level. Masks with integrated ozone detection represent an advanced evolution of personal protective equipment, offering users real-time awareness of this invisible health threat. For procurement specialists, safety managers, and product developers in environmental health, industrial safety, and consumer wellness markets, understanding how to source these sophisticated monitoring systems is essential.

Masks with integrated ozone detection are wearable sensing platforms that incorporate miniaturized ozone sensors, signal processing electronics, and user alert systems to measure ambient ozone concentrations in real-time, providing immediate warnings when levels exceed safe thresholds. These systems transform protective masks into proactive environmental monitors, empowering users to make informed decisions about exposure avoidance. Successful sourcing requires evaluating sensor technology, integration methods, data accuracy, and overall system reliability.

The global air quality monitor market is projected to reach $10.2 billion by 2028, with wearable devices as a key growth segment. According to the U.S. Environmental Protection Agency (EPA), exposure to ozone levels as low as 70 ppb (parts per billion) can cause respiratory inflammation and exacerbate conditions like asthma. For outdoor workers, athletes, and sensitive populations, personal ozone monitoring offers a critical layer of protection. Let's explore the key considerations for sourcing masks with integrated ozone detection.

What Ozone Sensor Technologies Are Suitable for Wearable Integration?

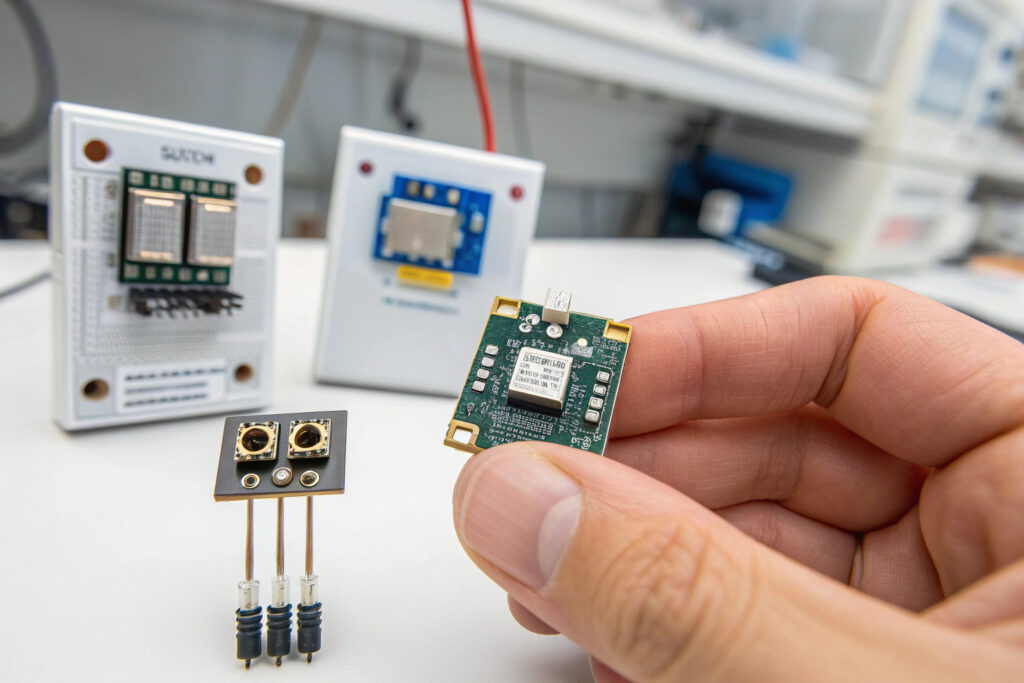

The core of the system is the ozone sensor. Traditional laboratory-grade analyzers are too large and power-hungry for masks, so miniaturized solid-state sensors are employed. Different technologies offer varying balances of accuracy, size, and power consumption.

How Do Metal Oxide Semiconductor (MOS) Sensors Work?

MOS sensors (often made of tin dioxide, SnO₂) change their electrical resistance when ozone molecules adsorb onto their surface and interact with oxygen vacancies. They are:

- Advantages: Small, low-cost, robust, and have long lifespans (typically 3-5 years). They can detect a wide range of concentrations (10-1000+ ppb).

- Disadvantages: They are less selective and can be cross-sensitive to other gases (like volatile organic compounds or nitrogen oxides). They also require a heated element to operate (usually 200-400°C), which consumes significant power.

For a mask, powering a heated MOS sensor continuously is challenging. However, they can be used in a pulsed heating mode to save energy. Their moderate accuracy is often sufficient for personal exposure warning (as opposed to regulatory-grade measurement).

What About Electrochemical and Optical Sensors?

- Electrochemical (EC) Sensors: Ozone diffuses through a membrane and causes a chemical reaction at an electrode, generating a small electrical current proportional to concentration.

- Advantages: Highly selective to ozone, very low power consumption (no heater needed), and good sensitivity at relevant levels (5-500 ppb).

- Disadvantages: Larger than MOS chips, have a shorter lifespan (typically 1-2 years) as the electrolyte dries out, and performance can drift with temperature and humidity.

- Optical (UV Absorption) Sensors: These miniaturized versions use a UV LED to shine light at a wavelength absorbed by ozone (around 254 nm). The amount of light absorbed indicates concentration.

- Advantages: Highly accurate and specific, with minimal drift and long life.

- Disadvantages: Currently larger and more expensive than other options, though they are rapidly miniaturizing. Power consumption is moderate.

For most wearable applications, low-power electrochemical sensors are currently the preferred balance of selectivity, size, and battery life. Companies like Alphasense and SPEC Sensors produce miniaturized EC sensor modules suitable for integration.

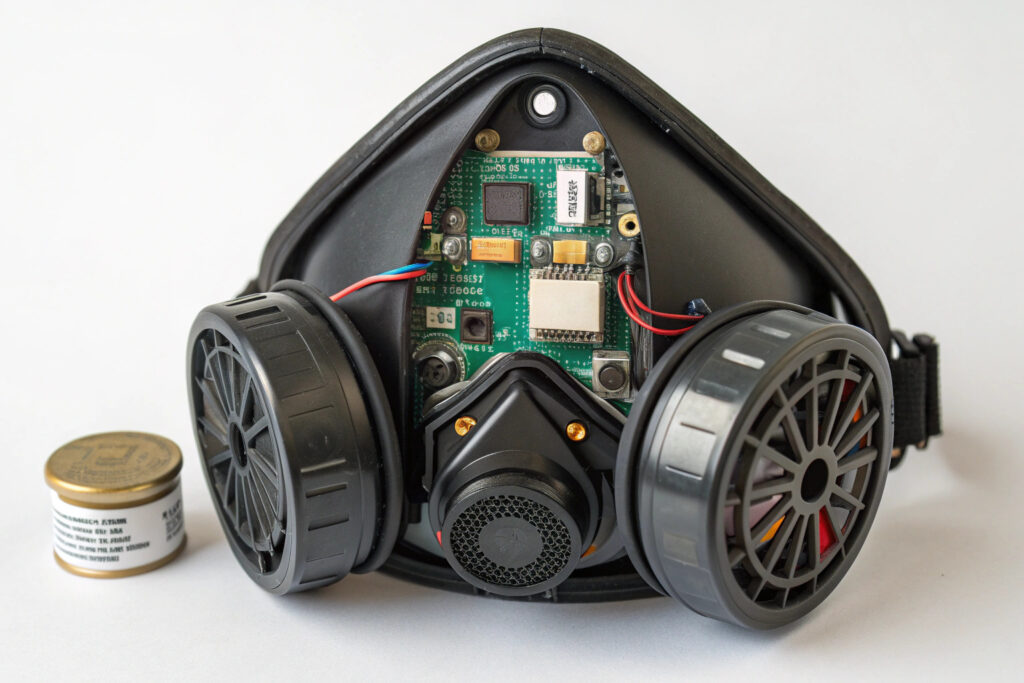

How Are Sensors and Electronics Integrated into a Functional Mask?

Designing a comfortable, functional mask that houses electronics and provides reliable airflow to the sensor is a significant engineering challenge.

How is Representative Air Sampled Without Compromising Protection?

A critical design issue is that the sensor must sample the ambient air the user is breathing, not the exhaled air inside the mask. This requires:

- Dedicated Sampling Inlet: A small, passive air inlet channel (with a dust filter) on the exterior of the mask that directs outside air to the sensor chamber. This inlet must be designed to not create a leak path for unfiltered air to enter the user's breathing zone.

- Pump vs. Passive Diffusion: For fastest response, a tiny micropump can actively draw air to the sensor. For lower power, the system can rely on passive diffusion, though this slows response time (to 30-60 seconds).

- Sensor Placement: The sensor is typically housed in a small module on the mask's exterior or on a side strap, connected via flexible printed circuit (FPC) to the main electronics board.

What Electronics and Power Management Are Needed?

The electronic system typically includes:

- Microcontroller (MCU): A low-power chip (e.g., ARM Cortex-M0+) that reads the sensor signal, applies calibration algorithms, and manages alerts.

- Power Management: Efficient DC-DC converters and battery charging/protection circuits. A key goal is maximizing battery life—a device should last at least 8-12 hours of continuous monitoring on a single charge.

- Connectivity: Bluetooth Low Energy (BLE) is standard for pairing with a smartphone app to log data, view trends, and adjust settings.

- User Alerts: On-mask alerts are essential. These include a multi-color LED (e.g., green/yellow/red), a vibration motor, and sometimes a tiny piezo buzzer.

The entire assembly must be lightweight, balanced, and protected from moisture (sweat, rain) and physical shock.

What Calibration, Accuracy, and Data Validation Are Required?

An ozone reading is only useful if it's reasonably accurate. Unlike a simple particle counter, gas sensors require careful calibration and compensation.

How are Sensors Calibrated for Individual Use?

Gas sensors, especially electrochemical ones, have unit-to-unit variability and are sensitive to environmental conditions.

- Factory Calibration: Each sensor module is calibrated by the manufacturer against known ozone concentrations. A calibration certificate with sensitivity and baseline values is provided.

- Temperature & Humidity Compensation: The onboard MCU must run algorithms that adjust the raw sensor reading based on real-time temperature and humidity data from additional sensors. This is crucial for accuracy in varying outdoor conditions.

- User Zeroing: Some systems include a "zero" function where the user can place the mask in a known clean-air environment (like an indoor space with an air purifier) to reset the baseline, helping to correct for sensor drift over weeks or months.

When sourcing, ask suppliers for detailed specifications on accuracy (e.g., ±10 ppb or ±10% of reading, whichever is greater), limit of detection, and response time.

How is Data Presented and Validated for the User?

The raw ppb number may be meaningless to many users. Effective systems translate data into actionable information:

- Air Quality Index (AQI) Integration: Convert the ozone concentration into the EPA's AQI scale for ozone, providing a familiar "Good," "Moderate," "Unhealthy" rating.

- Time-Weighted Averages: Calculate and alert based on 1-hour or 8-hour average exposures, which are the health standards used by regulatory bodies.

- Exposure Logging: The paired smartphone app should log location-tagged data, allowing users to review their daily or weekly exposure and identify high-risk locations or times.

Validation against a trusted, stationary air quality monitor (like a PurpleAir or a government station) can build user trust in the device's readings.

What Are the Primary Application Sectors and Regulatory Considerations?

Different use cases demand different feature sets and levels of robustness.

How is this Technology Used in Occupational Safety?

For workers in jobs with potential ozone exposure (e.g., welding, laser engraving, water treatment, airplane cabin crews), these masks serve as personal exposure monitors. Requirements are stricter:

- Data Logging for Compliance: The device must log detailed exposure data that can be downloaded for OSHA or other regulatory compliance records.

- Ruggedized Design: Must withstand harsh environments (dust, moisture, impacts).

- High-Visibility Alerts: Loud and distinct alarms to be heard in noisy workplaces.

In these settings, the mask's detection system may need to meet certain performance standards for industrial gas detectors.

What is the Consumer Wellness and Sports Market?

For runners, cyclists, and environmentally concerned citizens, the value is in personal awareness and avoidance.

- Lightweight and Stylish Design: Aesthetics and comfort are as important as accuracy.

- App Integration: Syncing with fitness apps (like Strava or Apple Health) to overlay air quality data with workout routes and performance metrics.

- Educational Content: The app should provide guidance on what the levels mean and what actions to take (e.g., "Ozone is high, consider moving your run to the morning.").

Regulatory requirements are less stringent, but claims about accuracy and health guidance must be truthful and not misleading (per FTC guidelines).

Conclusion

Sourcing masks with integrated ozone detection requires a focus on the sensor module's performance (prioritizing electrochemical sensors for their selectivity and low power), a well-engineered integration that allows for accurate ambient air sampling without compromising seal integrity, and a user-centric design that translates data into clear, actionable alerts. While not yet a mainstream consumer product, these devices fill a critical gap in personal air quality monitoring, offering protection against an invisible but harmful pollutant. As sensor technology continues to miniaturize and improve, and as public awareness of ozone's risks grows, ozone-detecting masks are poised to become an important tool for health-conscious individuals and safety-conscious organizations alike.

Ready to explore integrating ozone detection or other air quality sensing into your mask products? Contact our Business Director, Elaine, at elaine@fumaoclothing.com to discuss sourcing sensor modules, OEM development, or creating a custom smart mask solution for your target market.