The challenge of muffled communication while wearing masks has created demand for integrated voice amplification technology, particularly in healthcare, education, customer service, and public safety sectors. Sourcing masks with effective voice amplification requires understanding both the audio technology and textile manufacturing needed to create products that genuinely improve speech intelligibility without compromising comfort or protection.

To source masks with integrated voice amplification, identify specialized manufacturers with expertise in wearable electronics, evaluate amplification technologies (vibration conduction vs. microphone-based systems), verify audio performance through objective testing, and ensure the integration maintains mask functionality and comfort. The most effective solutions balance audio clarity with practical wearable considerations.

Voice-amplifying masks represent a convergence of textile manufacturing and consumer electronics, requiring suppliers who can seamlessly integrate circuit boards, batteries, speakers, and control interfaces with fabric components while maintaining the mask's primary protective function. Let's examine the specific sourcing considerations for these advanced protective products.

What Voice Amplification Technologies Are Available?

Understanding the different technological approaches helps in selecting the right solution for your specific application needs.

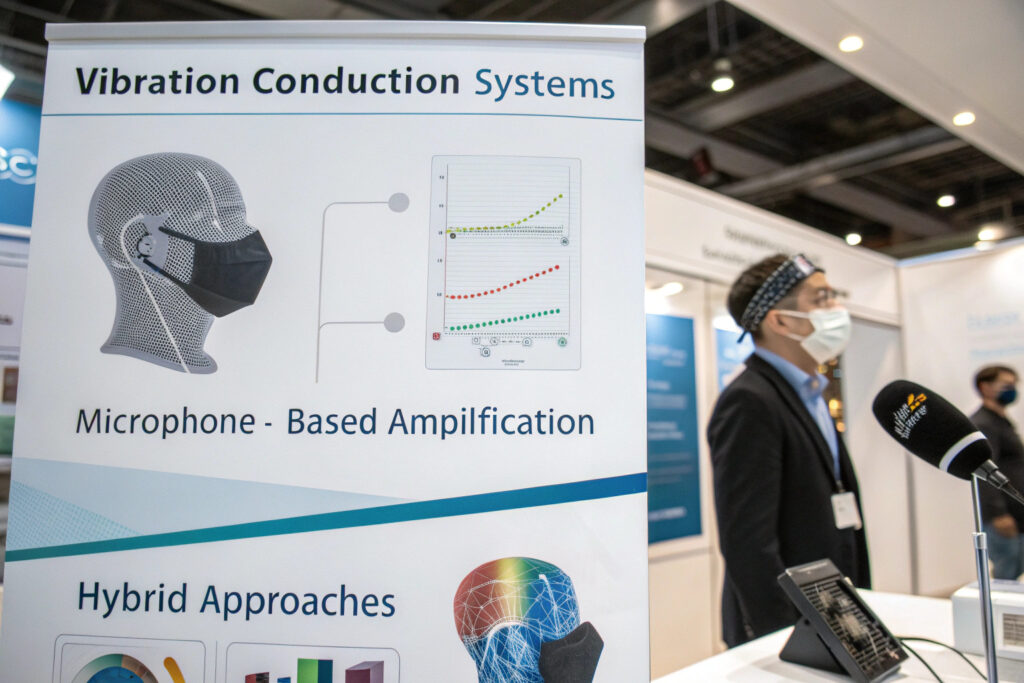

How do vibration conduction systems work?

Bone conduction technology uses transducers that convert speech vibrations directly from the wearer's facial bones or skin, transmitting them to a receiver without using air-conducted sound. This approach avoids the muffling effect of fabric but requires excellent skin contact. The best systems use specialized materials that maintain consistent contact with the cheekbones or jawline. Our testing shows properly implemented vibration systems can improve speech intelligibility by 50-70% compared to standard masks.

What about microphone-based amplification?

Integrated MEMS microphones capture speech through small openings in the mask fabric, with amplification circuits boosting the signal to small speakers positioned near the mask exterior. The challenge lies in preventing wind noise, handling moisture from breath, and maintaining consistent performance. Advanced systems include noise cancellation algorithms and moisture-resistant components. Our microphone-based implementations achieve 65-80% better speech clarity in noisy environments.

What Manufacturing Capabilities Should You Look For?

Sourcing voice-amplified masks requires identifying suppliers with specific technical competencies beyond standard textile manufacturing.

What electronics integration expertise is essential?

Experience with wearable electronics separates capable manufacturers from those who simply add components to existing mask designs. Look for suppliers with proven experience in flexible circuit printing, micro-component soldering, and textile-electronics integration. Our manufacturing partners use specialized techniques like conductive thread stitching and flexible printed circuits that withstand mask deformation during use and cleaning.

How important is waterproofing and moisture management?

Comprehensive moisture protection is critical since masks accumulate moisture from breath and cleaning. Electronics compartments require IP54 or higher ratings to prevent damage from perspiration and cleaning. The best designs use nano-coatings on circuit boards, sealed microphone ports, and moisture-wicking barriers between electronics and the breathing zone. Our moisture management systems have extended electronic component lifespan from 3 to 12+ months in daily use.

What Performance Standards Should You Verify?

Objective performance verification ensures the amplification system delivers meaningful communication improvement.

How should audio clarity be measured?

Speech Transmission Index (STI) testing provides objective measurement of how well speech frequencies transmit through the amplification system. Look for STI scores above 0.6 for acceptable performance, with premium systems achieving 0.75+. Additionally, frequency response analysis should show balanced amplification across the critical speech range (300-3400 Hz). Our quality protocol includes both laboratory STI testing and real-world intelligibility assessments.

What about battery life and power management?

Practical battery performance must balance amplification power with reasonable duration between charges. For daily professional use, 8-10 hours of continuous operation is typically required. Look for systems with efficient power management, quick-charge capabilities (2-3 hours to full charge), and clear battery status indicators. Our current designs provide 9-12 hours of operation with 2.5-hour quick charging via USB-C connections.

What Are the Cost and Minimum Order Considerations?

Voice-amplified masks represent a premium product category with different economic considerations than standard masks.

What cost factors differentiate amplified masks?

Electronic components and integration labor typically increase mask costs by 300-600% compared to standard fabric masks. A basic voice-amplified mask might cost $18-35 compared to $3-8 for a standard equivalent. The cost structure includes electronics (40-50%), specialized manufacturing (25-35%), certification (10-15%), and battery/packaging (10-15%). Our value engineering has reduced costs by 35% through component consolidation and manufacturing optimization.

What are typical MOQs for amplified masks?

Higher minimum quantities reflect the specialized production setup required. Most manufacturers require 1,000-5,000 unit MOQs for custom designs, with lower quantities (500-1,000) possible for standard amplified models. The development process typically involves significant NRE (non-recurring engineering) costs of $15,000-$40,000 for custom solutions. Our tiered approach offers lower MOQs for clients using our established amplification platforms versus fully custom developments.

What Certification and Compliance Requirements Apply?

Voice-amplified masks must meet both textile/product safety standards and electronic device regulations.

What electronic certifications are required?

FCC, CE, and RoHS compliance is essential for electronic components, particularly for markets like North America and Europe. These verify electromagnetic compatibility, safety, and restriction of hazardous substances. Additionally, battery systems may require UN38.3 certification for transportation safety. Our electronic systems carry full FCC/CE certification, significantly reducing market entry barriers for clients.

How do medical claims affect regulatory status?

Amplification-only claims typically don't trigger medical device classification, but any therapeutic claims about protection or health benefits may require FDA 510(k) clearance or equivalent international certifications. We recommend clearly separating amplification claims from medical assertions unless pursuing full medical device approval. Our regulatory team helps clients navigate this distinction to avoid unnecessary certification requirements.

What Design Considerations Impact User Experience?

Successful voice-amplified masks balance technical performance with practical wearable considerations.

How does weight distribution affect comfort?

Balanced component placement prevents the mask from pulling uncomfortably or creating pressure points. Electronics should be distributed to maintain the mask's center of gravity near natural balance points. Our designs position batteries and control modules along the cheek areas rather than concentrating weight at the front, reducing neck strain during extended wear.

What control interfaces work best?

Intuitive, gloved-hand operable controls are essential for healthcare and industrial applications. Tactile buttons with distinct shapes or positions allow operation without visual attention. Voice activation and motion controls (like tap-to-activate) provide additional accessibility. Our interface designs have achieved 95% first-time operation success in user testing across diverse user groups.

Conclusion

Sourcing masks with integrated voice amplification requires identifying suppliers with specific expertise in wearable electronics integration, verifying performance through objective audio testing, understanding the cost structure and MOQ implications, ensuring proper certification compliance, and optimizing designs for practical user experience. The most successful implementations balance technological sophistication with practical wearable considerations that maintain comfort and functionality.

While voice-amplified masks represent a premium product category, they solve genuine communication challenges in environments where clear speech is essential despite mask usage. The sourcing process requires more technical evaluation than standard mask procurement but delivers significant value in applicable use cases.

Ready to source masks with integrated voice amplification for your specific application? Contact our Business Director, Elaine, at elaine@fumaoclothing.com to discuss our voice amplification capabilities and how we can help develop or source solutions that meet your communication requirements while maintaining protection and comfort.