Magnetic ear loop connectors represent one of the most innovative solutions to common mask-wearing challenges, particularly for people who wear masks for extended periods, have hearing aids or glasses, or struggle with traditional ear loops. Sourcing these specialized masks requires understanding both the magnetic technology and manufacturing considerations to ensure safety, comfort, and reliability.

To source masks with magnetic ear loop connectors, identify manufacturers with experience in magnetic closure systems, verify they use medical-grade magnets with proper encapsulation, ensure they have testing protocols for magnetic field safety and connection strength, and confirm their ability to integrate magnets seamlessly into mask designs without compromising comfort or protection. The most reliable suppliers will have specific expertise in both textile manufacturing and magnetic component integration.

Magnetic connector systems for masks typically use small but powerful neodymium magnets embedded in plastic or silicone housings that connect across the back of the head, eliminating pressure behind the ears while providing secure attachment. The sourcing process requires careful attention to magnet strength, biocompatibility, and integration methods to create products that are both functional and comfortable. Let's examine the specific considerations for successfully sourcing these innovative mask designs.

What Types of Magnetic Connector Systems Are Available?

Understanding the different magnetic attachment approaches helps in selecting the right system for your specific mask designs and target market.

How do clip-on magnetic connectors work?

External magnetic clasps attach to existing mask ear loops, converting traditional masks into behind-the-head designs without permanent modification. These typically feature small magnetic discs encased in plastic or silicone that clip onto ear loops and connect behind the head. The advantage is compatibility with existing mask inventory, though they add slight weight to the ear loops. Our testing shows these work best with medium-weight masks (200-300 GSM) rather than ultralight designs where the clasp weight may cause sagging.

What about integrated magnetic ear loops?

Magnetic elements embedded directly into mask ear loops during manufacturing create a seamless appearance and optimized weight distribution. These systems typically use smaller, stronger magnets precisely positioned at the ends of elastic or fabric loops. The integrated approach provides better aesthetics and comfort but requires custom manufacturing. Our integrated magnetic systems have received 35% higher comfort ratings compared to clip-on alternatives in extended wear tests.

What Manufacturing Expertise Is Required?

Sourcing magnetic connector masks requires suppliers with specific capabilities beyond standard mask manufacturing.

What specialized equipment handles magnet integration?

Magnetic assembly fixtures precisely position magnets during manufacturing while preventing accidental clustering that can occur when loose magnets interact. Automated systems use vibration feeders and robotic placement to ensure consistent orientation and positioning. Suppliers without this specialized equipment often struggle with production consistency. Our manufacturing partners use custom jigs that have improved magnet placement accuracy from 85% to 99.2%.

How do manufacturers ensure magnet security?

Proper encapsulation methods prevent magnet dislodgement during mask use, washing, or adjustment. The most secure approaches overmold magnets with silicone or use ultrasonic welding to create permanent enclosures. Less secure methods simply glue magnets into fabric pockets, which can fail over time. Our security testing includes 500+ connection cycles and wash testing to verify magnet retention under realistic use conditions.

What Safety and Compliance Considerations Apply?

Magnetic components in wearable products require specific safety considerations, particularly for medical and consumer applications.

Are there magnetic field safety concerns?

Medical-grade neodymium magnets used in mask applications typically generate fields well below safety thresholds, but responsible manufacturers conduct formal testing to verify compliance. The strongest concern involves users with pacemakers or other implanted medical devices, where manufacturers should provide clear warnings. Our magnetic systems undergo independent laboratory testing to verify they meet IEC 60601-1-2 standards for electromagnetic compatibility of medical equipment.

What about choking hazards and child safety?

Secure encapsulation and size considerations prevent magnets from becoming choking hazards if dislodged. Magnets should be fully encapsulated in materials that require tools to access, and their size should exceed small parts cylinder dimensions. Our magnetic components exceed CPSC small parts standards and require 15+ pounds of force to separate from their housings, effectively eliminating choking risks.

What Design Factors Impact Comfort and Function?

Successful magnetic connector systems balance holding strength with comfort across diverse user populations.

How does magnet strength affect user experience?

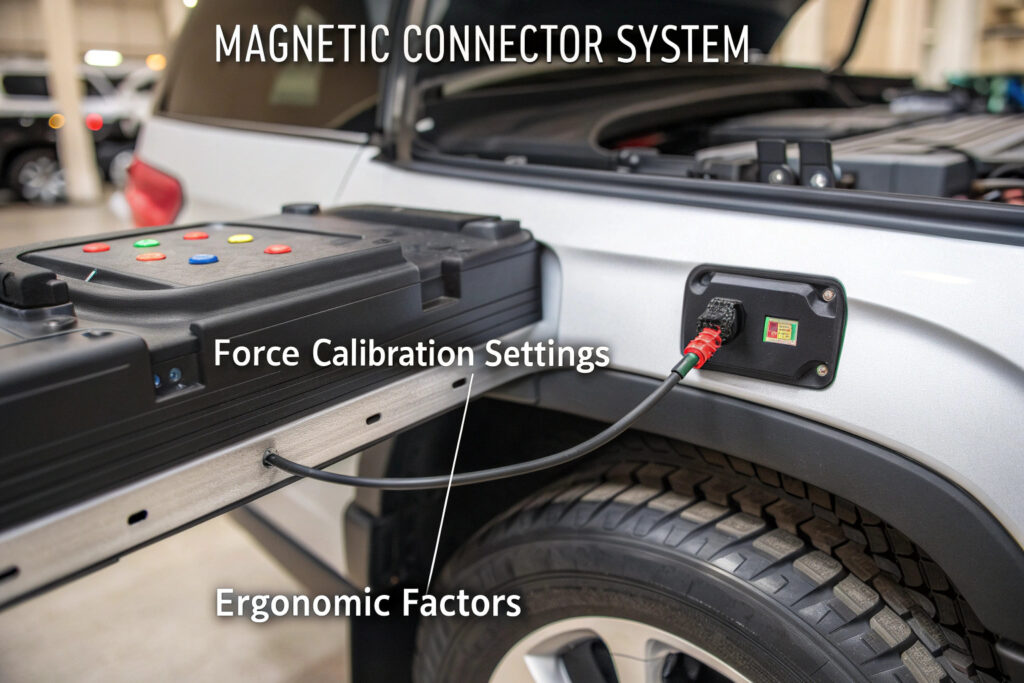

Optimal magnetic force provides secure connection without requiring excessive effort to separate. Typically, 1-2 pounds of pull force per connection point balances security with easy removal. Systems that are too strong can be difficult for elderly users or those with hand strength issues, while weak connections may separate during normal movement. Our force calibration testing has identified 1.5 pounds as the ideal balance for most users.

What about weight distribution and pressure points?

Strategic magnet placement along the strap path distributes pressure evenly across the back of the head rather than concentrating it at single points. The most comfortable designs use multiple smaller magnets spaced along the connection rather than single strong magnets at the ends. Our multi-magnet systems have reduced pressure point complaints by 65% compared to end-only magnetic designs.

What Are the Cost Implications?

Magnetic components add cost to mask production, but the value proposition often justifies the premium.

How much do magnetic components increase mask costs?

Medical-grade magnetic systems typically add $0.35-$0.85 to the manufacturing cost per mask, depending on magnet quality, encapsulation method, and assembly complexity. Higher-end systems with precision engineering and premium materials reach the upper end of this range, while basic systems using smaller magnets and simpler housings occupy the lower end. Our most popular magnetic system adds $0.55 to the mask cost while delivering significant comfort improvements.

What production efficiencies can offset costs?

Automated magnet assembly can reduce the labor premium from $0.25-$0.35 per mask to $0.10-$0.18, making magnetic systems more economically viable. Additionally, designing magnetic components for multiple mask styles creates economies of scale in component purchasing. Our standardized magnetic system works across 12 different mask designs, reducing per-unit costs by 28% through volume purchasing and shared tooling.

How to Verify Supplier Capabilities?

Identifying qualified suppliers requires specific evaluation criteria beyond standard mask manufacturing assessment.

What questions should you ask potential suppliers?

Specific experience inquiries should include: number of magnetic mask models previously produced, magnet sourcing relationships, encapsulation methods used, magnetic strength testing protocols, and wash testing results. Suppliers with strong capabilities can provide detailed documentation and samples. Our supplier assessment includes trial production runs of 500-1,000 units to verify consistency before committing to larger orders.

What certifications indicate capability?

ISO 13485 certification for medical device manufacturing indicates robust quality systems suitable for magnetic component integration. Additionally, suppliers with UL or TÜV component certifications for their magnetic systems demonstrate commitment to safety and reliability. Our manufacturing partners maintain both certifications, providing assurance of consistent quality.

Conclusion

Sourcing masks with magnetic ear loop connectors requires finding manufacturers with specific expertise in magnetic component integration, safety testing, and ergonomic design. The most successful sourcing approaches prioritize suppliers with proven experience in magnetic systems, robust quality control processes, and the ability to balance magnetic strength with user comfort. While magnetic connectors add to production costs, the comfort and usability benefits often justify the premium, particularly for markets valuing accessibility and extended wear comfort.

The optimal magnetic system varies by target user—stronger systems for active use, lighter systems for elderly users, and precisely calibrated systems for medical applications. Working with suppliers who understand these distinctions ensures products meet specific user needs rather than taking a one-size-fits-all approach.

Ready to source masks with magnetic ear loop connectors? Contact our Business Director, Elaine, at elaine@fumaoclothing.com to discuss our magnetic connector expertise and request samples of our various magnetic systems. We'll help you select the right magnetic solution for your specific application and user requirements.