The challenge of ear loop failure has plagued reusable mask users since the beginning of the pandemic, with elastic degradation rendering otherwise functional masks unusable. Masks with replaceable elastic ear loops address this single point of failure while offering customization options for comfort and fit. Sourcing these innovative designs requires understanding both the manufacturing considerations and the market demand drivers.

To source masks with replaceable elastic ear loops, identify manufacturers specializing in modular designs, specify attachment mechanisms like silicone toggles, snap buttons, or hook-and-loop systems, and ensure replacement components are readily available. The most successful implementations balance ease of replacement with secure attachment that maintains protection levels.

Replaceable ear loop systems transform masks from disposable items into sustainable accessories while solving practical problems like ear loop breakage, sizing issues, and the desire for style variations. However, they introduce manufacturing complexity that not all suppliers can effectively manage. Let's examine the sourcing considerations, manufacturing capabilities, and market factors that will guide your procurement strategy.

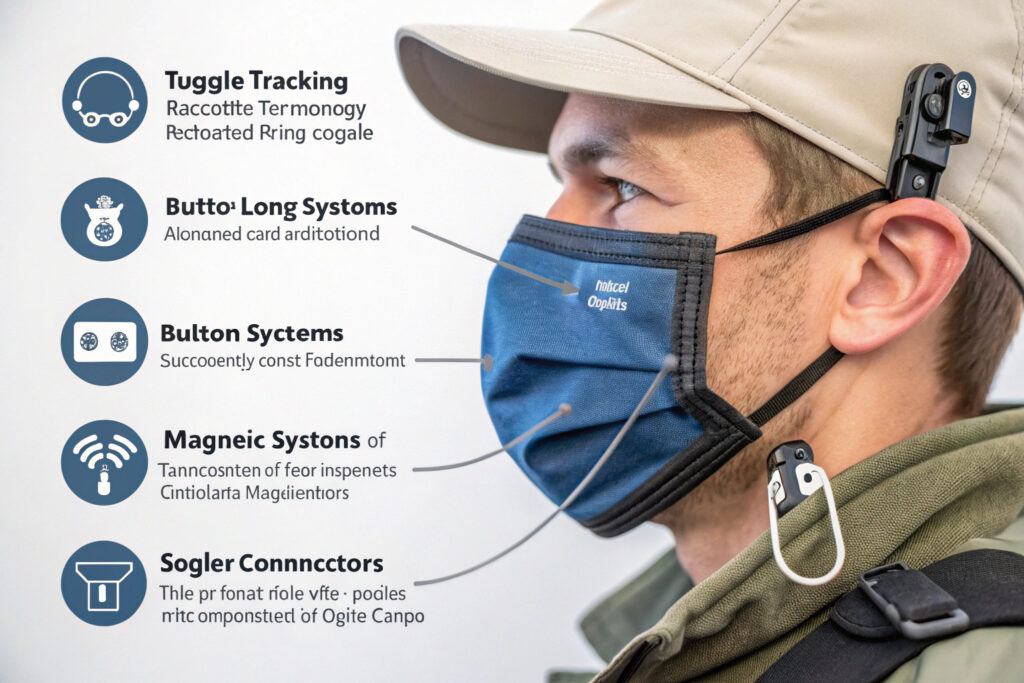

What Attachment Mechanisms Work Best for Replaceable Loops?

The method used to attach replaceable ear loops significantly impacts both user experience and manufacturing feasibility.

How do silicone toggle systems function?

Silicone toggle and cord lock systems work by threading elastic through mask anchor points and securing with adjustable toggles. This approach allows for infinite adjustability while providing secure attachment. The best designs use medical-grade silicone toggles that grip elastics firmly without damaging them. Our testing shows toggle systems maintain secure attachment through 200+ removal and reattachment cycles while allowing length adjustments for perfect fit. Manufacturing requires specialized equipment for toggle application but uses standard elastic materials.

What about snap button attachments?

Snap button systems provide the most secure attachment but require more complex mask construction. Four-piece snaps (male and female components on both mask and elastic) create reliable connections that won't accidentally detach. The manufacturing challenge involves precise placement of snap components and reinforcement of attachment points. Our snap-button masks use reinforced fabric patches at connection points to prevent tearing, with snap placement accuracy within 1mm tolerance.

What Manufacturing Capabilities Should You Look For?

Sourcing replaceable ear loop masks requires identifying suppliers with specific technical capabilities beyond standard mask production.

What specialized equipment is needed?

Suppliers need attachment-specific machinery such as snap presses, ultrasonic welding equipment for hook-and-loop systems, or specialized jigs for toggle assembly. Standard mask sewing operations won't efficiently produce these designs. Our manufacturing partners use automated snap attachment systems that can apply 1,200+ snap sets per hour with consistent quality, making the additional cost manageable at scale.

How important is component standardization?

Standardized connection systems across your product line ensure replacement parts work with multiple mask styles, simplifying inventory management for both you and your customers. The most successful implementations use the same attachment mechanism across all products, allowing customers to mix and match masks and elastics. Our modular system uses three standardized connector types that work across 12 different mask styles.

What Are the Cost Implications Compared to Standard Masks?

Replaceable ear loop systems impact both manufacturing costs and consumer value proposition.

How much do replaceable systems add to manufacturing costs?

Additional component and assembly costs typically increase manufacturing expenses by 20-35% compared to standard masks. This includes the cost of attachment mechanisms, reinforced attachment points, and more complex assembly processes. However, these costs can be partially offset by simplified elastic sourcing and reduced waste from misapplied permanent loops. Our cost analysis shows a 28% manufacturing cost increase is typically justified by a 50-70% retail price premium and significantly extended product lifespan.

What about the economics of replacement part sales?

Replacement elastic kits create ongoing revenue streams beyond the initial mask purchase. Well-designed systems encourage customers to purchase multiple elastic types (different colors, lengths, materials) and replacement sets. Our data shows that 35% of customers purchase additional elastic sets within 90 days of mask acquisition, with average additional spending of 40-60% of the original mask price.

What Design Considerations Impact User Experience?

Successful replaceable ear loop designs balance easy replacement with secure attachment during use.

How easy should replacement be for users?

The ideal system allows tool-free replacement in under 30 seconds while being secure enough to prevent accidental detachment. Systems that are too difficult to change discourage use of the replaceable feature, while systems that detach too easily compromise protection. Our user testing indicates that silicone toggle systems achieve the best balance, with average replacement time of 15-22 seconds and zero accidental detachments in 500 hours of testing.

What about comfort and adjustability?

Length adjustability provides significant comfort advantages by allowing users to customize tension. Systems that combine replaceability with adjustability address two common mask complaints simultaneously. Our adjustable-replaceable system allows 4cm of length adjustment, accommodating the 95th percentile of adult head sizes without excessive looseness on smaller individuals.

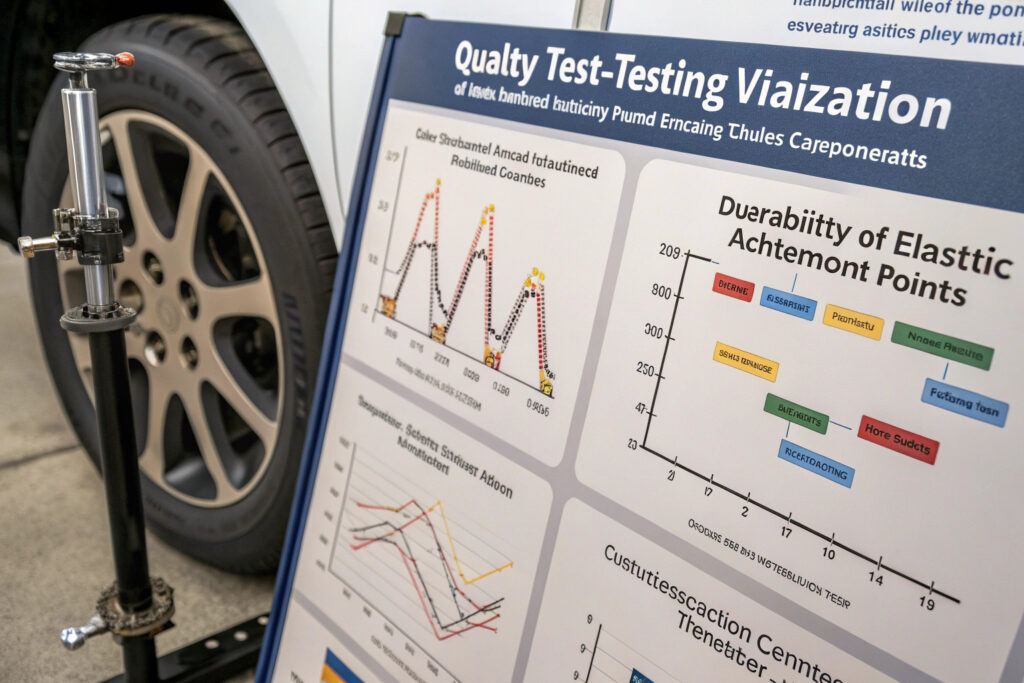

What Quality and Durability Standards Apply?

Replaceable systems must maintain their functionality through numerous replacement cycles without compromising mask integrity.

How many replacement cycles should the system withstand?

Minimum 50-100 replacement cycles without significant degradation of connection points or elastic materials represents a reasonable quality standard. This ensures the system remains functional through the mask's expected lifespan. Our quality testing involves automated replacement cycling, with systems required to maintain integrity through 150 cycles—approximately three years of weekly elastic changes.

What about attachment point reinforcement?

Reinforced connection areas prevent tearing at stress points, particularly important for systems using snaps or hooks that concentrate force. The most effective reinforcements use multiple layers of fabric, ultrasonic welding, or fabric stabilizers. Our reinforcement approach has reduced attachment point failures from 8% to under 0.5% in accelerated lifespan testing.

What Market Segments Value This Feature Most?

Understanding which customer groups prioritize replaceable ear loops helps target your sourcing and marketing efforts.

Why do healthcare organizations value this feature?

Reduced waste and cost savings make replaceable ear loop systems attractive for healthcare settings where masks see heavy use. The ability to quickly replace damaged elastics without discarding entire masks represents significant operational savings. Our healthcare clients report 60-70% reduction in mask replacement costs after implementing replaceable loop systems.

How does this feature appeal to sustainability-focused consumers?

Extended product lifespan aligns with circular economy principles by addressing the most common point of mask failure. Environmentally conscious consumers appreciate reducing waste while maintaining protection. Our sustainability-focused lines with replaceable loops command 40-50% price premiums while achieving 30% higher customer satisfaction scores.

Conclusion

Sourcing masks with replaceable elastic ear loops requires identifying manufacturers with specific technical capabilities, understanding the cost-quality trade-offs of different attachment systems, and recognizing the market segments that value this feature most. The most successful implementations create systems that are easy for consumers to use while maintaining the security and protection of permanent attachment methods.

The additional investment in replaceable systems pays dividends through extended product lifespan, reduced waste, additional revenue from replacement part sales, and access to premium market segments. As mask usage evolves from emergency measure to ongoing practice, features that enhance sustainability and customization will increasingly differentiate products in a competitive market.

Ready to source masks with replaceable elastic ear loops? Contact our Business Director, Elaine, at elaine@fumaoclothing.com to discuss our modular mask designs and manufacturing capabilities. We'll help you implement replaceable systems that balance user convenience, manufacturing efficiency, and product security.