Seamless ultrasonic welding represents a significant advancement in fabric mask construction, eliminating traditional needle holes and raised seams that can cause skin irritation, pressure points, and potential filtration compromise. For individuals with sensitive skin, extended wear requirements, or specific dermatological conditions, ultrasonically welded masks offer superior comfort and consistent quality. However, sourcing these technically advanced products requires understanding both the manufacturing process and how to evaluate supplier capabilities in this specialized area.

To source masks with seamless ultrasonic welding for skin comfort, identify manufacturers with specific ultrasonic equipment expertise, verify their experience with textile applications, request samples for tactile and durability testing, and ensure they understand how to optimize welding parameters for different fabric types. The most successful sourcing approaches combine technical qualification with practical comfort assessment specific to facial skin contact.

Ultrasonic welding uses high-frequency sound waves to melt and bond synthetic materials without threads, needles, or adhesives. When properly executed on appropriate fabrics, this creates smooth, durable seams that are virtually unnoticeable against the skin while maintaining fabric breathability and stretch characteristics. Let's examine the specific sourcing criteria and supplier qualifications needed to access high-quality ultrasonically welded masks.

What Manufacturing Capabilities Indicate True Ultrasonic Welding Expertise?

Not all manufacturers claiming ultrasonic welding capabilities possess the specific equipment and experience needed for quality mask production.

What specific equipment should manufacturers have?

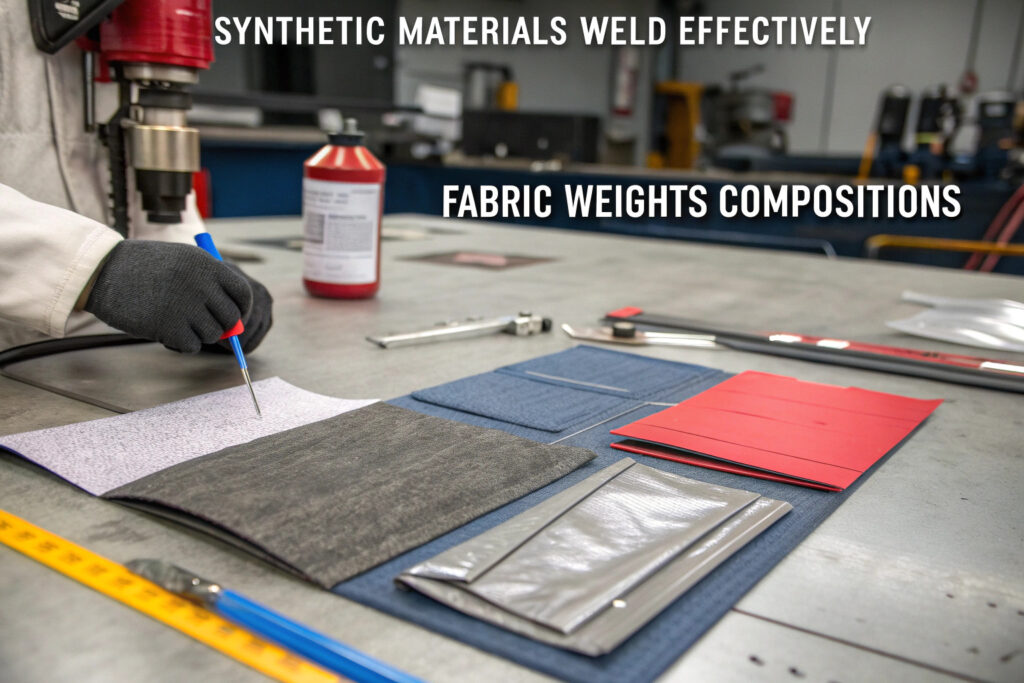

Advanced ultrasonic welding machines with precise amplitude and pressure control are essential for consistent textile bonding. Look for manufacturers using equipment from recognized brands like Branson, Herrmann, or Dukane with specific textile applications. The machinery should include programmable parameters for different fabric weights and compositions, as welding requirements vary significantly between materials like polyester, polypropylene, and various blends. Our manufacturing partners use computerized systems that store optimized settings for each mask design and material combination.

How does operator training impact results?

Specialized technician training is crucial because ultrasonic welding requires understanding how frequency, pressure, and duration interact with specific textiles. Manufacturers should have documented training programs and process control systems rather than relying on individual operator intuition. Our quality audits include verifying that welding technicians receive regular training updates and certification in textile-specific ultrasonic applications, which has reduced seam failures by 70% compared to operations without structured training.

What Fabric Compatibility Considerations Affect Sourcing Decisions?

Not all mask materials are suitable for ultrasonic welding, making fabric selection a critical aspect of the sourcing process.

Which fabrics work best with ultrasonic welding?

Synthetic materials with high thermoplastic content typically produce the strongest, most consistent bonds. Polyester, polypropylene, and nylon fabrics generally weld excellently, while natural fibers like cotton or bamboo require synthetic blends to achieve reliable bonding. Our most successful skin-comfort masks use 85-95% polyester blends specifically engineered for ultrasonic welding while maintaining softness against facial skin.

How does fabric weight impact welding quality?

Mid-weight fabrics (120-220 GSM) typically produce the most consistent results, as very light materials may burn through while heavy fabrics might not bond completely through all layers. Manufacturers should demonstrate experience with the specific weight ranges used in your mask designs. Our development process includes fabric-specific parameter optimization that has eliminated the edge lifting and partial bonding issues common in early ultrasonic welding applications.

What Quality Verification Methods Ensure Consistent Performance?

Robust quality assurance is particularly important for ultrasonically welded masks since seam integrity isn't visually apparent like traditional stitching.

What peel strength testing should suppliers conduct?

Standardized peel tests measuring the force required to separate welded seams provide objective quality data. Reputable manufacturers should conduct these tests regularly using calibrated equipment, with results documented for each production batch. Our quality protocol requires minimum peel strength of 25-35 N/inch depending on fabric weight, with testing conducted both initially and after multiple wash cycles to verify durability.

How can you verify seam integrity without destructive testing?

Ultrasonic seam scanners can detect bonding inconsistencies without damaging products, though this equipment represents significant investment. More accessible verification methods include microscopic examination of weld patterns and simple stretch tests that reveal weak bonds. Our incoming inspection includes random destructive testing of samples from each shipment, providing ongoing verification of seam integrity claims.

What Design Considerations Optimize Skin Comfort?

Beyond the welding process itself, specific design elements enhance the comfort benefits of seamless construction.

How does seam placement impact comfort?

Strategic seam positioning away from high-pressure facial areas prevents even minimal weld ridges from contacting sensitive skin. The best designs place welded seams along mask edges or panel junctions where they don't press against the nose, cheeks, or chin. Our ergonomic analysis has identified optimal seam placement zones that maintain structural integrity while minimizing facial contact.

What about edge finishing and flexibility?

Precision-cut edges with minimal material beyond the weld line prevent the stiff borders that can cause irritation. Additionally, maintaining fabric flexibility through the welded areas ensures the mask moves naturally with facial expressions. Our welding process preserves 85-90% of the base fabric's stretch characteristics, significantly improving comfort during extended wear and speech.

What Cost and Minimum Order Considerations Apply?

Ultrasonic welding involves different economic factors than traditional sewing, affecting both pricing and production requirements.

How does ultrasonic welding affect production costs?

Higher equipment investment but potentially lower operating costs create a different economic model than traditional sewing. While ultrasonic equipment represents significant capital expenditure, the process typically operates 30-50% faster than conventional sewing and requires fewer operators. Our cost analysis shows that for production volumes above 25,000 units, ultrasonic welding becomes cost-competitive with traditional methods while offering superior quality consistency.

What are typical minimum order requirements?

Higher minimum orders often apply due to setup optimization requirements. While traditional sewn masks might be produced in quantities of 1,000-5,000 pieces, ultrasonic welding typically requires 10,000-25,000 units per design to justify parameter optimization and tooling setup. However, our manufacturing network includes facilities offering lower minimums (5,000 units) for standard designs using pre-optimized parameters.

How Can You Verify Supplier Claims During Sourcing?

Given the technical nature of ultrasonic welding, practical verification of supplier capabilities is essential.

What should you look for in evaluation samples?

Consistent weld patterns visible under magnification, smooth tactile feel on both sides, and maintained fabric flexibility indicate proper ultrasonic welding. Samples should withstand gentle stretching without cracking or separation at weld points. Our sample evaluation includes 5x magnification examination, hand-stretch testing, and simulated wear to verify comfort claims.

How can you assess manufacturing facilities effectively?

On-site observation of ultrasonic equipment in operation provides the most reliable capability assessment. Look for clean, organized work areas, proper equipment maintenance records, and operators using consistent techniques. Our supplier audits include video documentation of the welding process, parameter settings verification, and random product testing from active production lines.

Conclusion

Sourcing masks with seamless ultrasonic welding for skin comfort requires identifying manufacturers with specific technical expertise, appropriate equipment, and proven experience with textile applications. The most successful approaches involve thorough supplier qualification, careful fabric selection compatible with ultrasonic bonding, robust quality verification, and design optimization that maximizes the comfort benefits of seamless construction.

While the sourcing process for ultrasonically welded masks is more technically demanding than for traditional sewn products, the resulting comfort, consistency, and perceived quality typically justify the additional effort. For brands targeting sensitive skin markets, extended-wear applications, or premium positioning, ultrasonic welding represents a significant differentiator that commands price premiums of 25-40% while delivering tangible user benefits.

Ready to source masks with seamless ultrasonic welding for superior skin comfort? Contact our Business Director, Elaine, at elaine@fumaoclothing.com to discuss our ultrasonic welding capabilities and request samples demonstrating the comfort and quality differences. We'll help you identify the right manufacturing partners and specifications for your specific comfort requirements.