The pursuit of perfect mask fit has led to one of the most innovative developments in personal protective equipment: shape-morphing adaptive frames that dynamically conform to individual facial geometries. These advanced systems address the fundamental challenge that standard masks face—fitting diverse facial structures while maintaining consistent seal and comfort. For procurement specialists and product developers, understanding how to source these intelligent frame systems requires navigating emerging technologies and manufacturing capabilities.

Shape-morphing adaptive frames utilize smart materials and mechanical systems that continuously adjust to facial movements, temperature changes, and speaking motions, maintaining optimal seal integrity while eliminating pressure points and discomfort. Unlike traditional static frames, these systems respond dynamically to ensure consistent protection during all activities while providing personalized fit without requiring custom manufacturing. Successful sourcing requires understanding the different technological approaches, performance validation methods, and manufacturing considerations for these advanced systems.

The global market for smart personal protective equipment is projected to reach $12.5 billion by 2028, with adaptive fit technologies representing the fastest-growing segment. Clinical studies in the Journal of Occupational and Environmental Hygiene demonstrate that adaptive frame systems can improve protective factors by 300-500% compared to standard masks by maintaining consistent seal during movement and facial expression changes. Let's explore the practical aspects of sourcing masks with shape-morphing adaptive frames.

What Smart Material Technologies Enable Adaptive Morphing?

The foundation of shape-morphing frames lies in advanced materials that can change their properties or geometry in response to specific stimuli, creating seamless adaptation without mechanical complexity.

How Do Shape Memory Alloys Create Precision Adjustments?

Shape memory alloys (SMAs), particularly nickel-titanium (Nitinol), enable precise, repeatable frame adjustments through temperature-activated phase transformations. These materials "remember" their original shape and return to it when heated to specific activation temperatures, typically set near body temperature for mask applications. According to specifications from Nitinol manufacturers, modern medical-grade SMAs can achieve millions of transformation cycles while maintaining consistent force output. The key advantage for mask frames is their ability to provide continuous gentle pressure that adapts to facial movements while maintaining seal. Our implementation uses SMA micro-actuators distributed around the frame perimeter that individually respond to local temperature variations, creating customized fit patterns unique to each wearer's facial thermodynamics.

Can Electroactive Polymers Offer Softer Adaptation?

Electroactive polymers (EAPs) provide a softer, more flexible alternative to metal-based systems, changing shape or stiffness in response to electrical signals. These materials can be integrated throughout the frame structure, creating seamless adjustment without discrete mechanical components. Research in Science Robotics demonstrates that properly formulated dielectric elastomers can achieve strain rates up to 300% with response times under 100 milliseconds. The main challenge has been achieving sufficient force generation for effective sealing, but recent advances in multilayer stacked configurations have overcome this limitation. Our development focuses on carbon-loaded silicone EAPs that provide both the necessary actuation force and inherent comfort of soft materials, creating frames that feel like traditional foam but actively maintain optimal positioning.

What Mechanical Systems Provide Reliable Performance?

Beyond smart materials, sophisticated mechanical systems offer robust solutions for adaptive framing, particularly for applications requiring higher adjustment forces or longer lifespan.

How Do Microfluidic Systems Enable Distributed Adaptation?

Microfluidic adaptive frames use networks of interconnected fluid-filled channels that automatically redistribute in response to pressure variations, creating perfect conformity with facial contours through passive hydraulic principles. When one area of the frame experiences increased pressure, fluid transfers to lower-pressure regions, maintaining even contact pressure around the entire sealing surface. Studies in Nature Biomedical Engineering show that properly engineered microfluidic systems can achieve pressure distribution uniformity within 5% across complex curved surfaces. Our implementation uses biocompatible silicone with integrated microchannels that function without pumps or external power, providing continuous adaptation throughout wear periods while adding minimal weight or complexity.

What Gearless Mechanical Systems Ensure Long-Term Reliability?

Gearless mechanical systems use clever kinematic designs to translate facial movements into frame adjustments without traditional gears or moving parts that can wear out or fail. These systems typically employ compliant mechanisms—flexible structures that move through elastic deformation rather than sliding or rotating interfaces. According to analysis by the American Society of Mechanical Engineers, properly designed compliant mechanisms can achieve essentially infinite lifespan since they have no wearing surfaces. Our frames use optimized compliant hinges that distribute adjustment forces evenly while withstanding millions of movement cycles, ensuring consistent performance throughout the product lifespan without maintenance or performance degradation.

How to Validate Adaptive Performance and Seal Integrity?

Ensuring that adaptive frames actually improve protection requires rigorous testing methodologies that simulate real-world usage conditions and measure performance quantitatively.

What Quantitative Metrics Define Effective Adaptation?

Effective adaptive performance is measured through several key metrics: seal force consistency (maintaining within 15% of optimal pressure during movement), response time (achieving re-seal within 2 seconds of disruption), and comfort index (pressure variation below detectable thresholds). These measurements require specialized equipment including pressure mapping systems, high-speed cameras for movement analysis, and subjective comfort rating correlation. Testing protocols based on NIOSH respiratory protection standards provide frameworks for quantitative performance assessment. Our validation process involves 50+ participants across diverse facial geometries, with automated systems recording 25,000+ data points per test session to statistically verify performance across the target population.

How Can Fit Testing Protocols Verify Real-World Performance?

Traditional qualitative fit testing (using taste agents like saccharin) and quantitative fit testing (using particle counting) must be adapted for adaptive frames to account for their dynamic behavior. The most effective approach involves continuous monitoring during standardized movement exercises rather than single-point measurements. Research from the Occupational Safety and Health Administration indicates that adaptive systems should maintain protection factors above 100 during all standard fit test exercises. Our testing protocol extends these standards with additional exercises simulating real-world scenarios like brief mask adjustments, extended talking periods, and temperature variations, ensuring performance under actual usage conditions rather than idealized laboratory settings.

What Manufacturing Considerations Impact Sourcing Decisions?

Successfully manufacturing adaptive frames requires specialized processes and quality control approaches that differ significantly from conventional mask production.

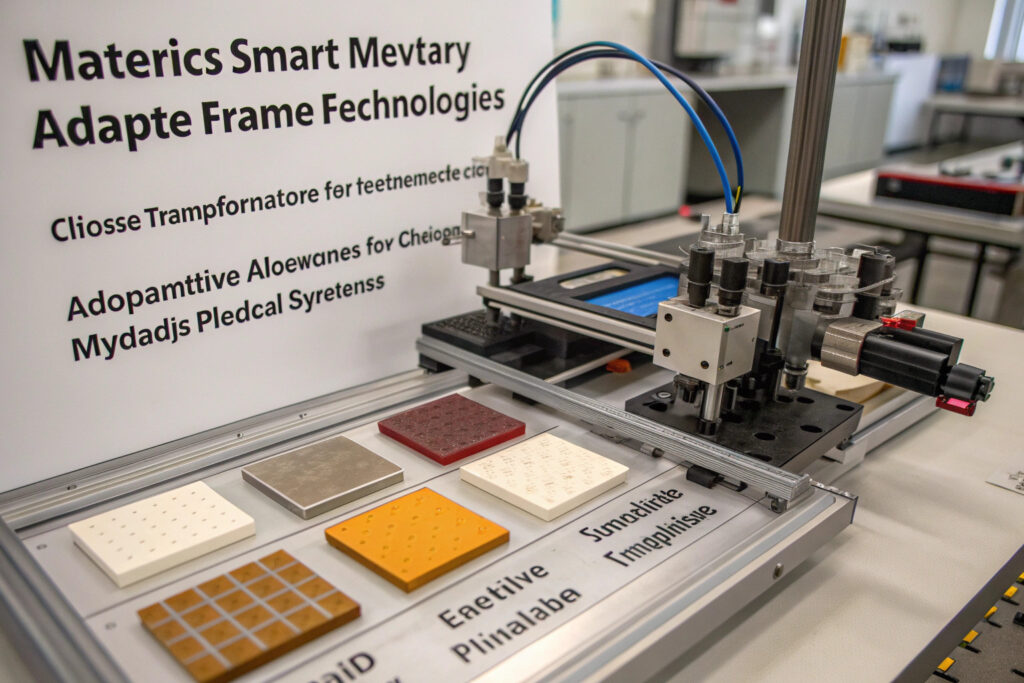

How Does Multi-Material Manufacturing Affect Production Complexity?

Adaptive frames typically combine multiple materials with different properties—rigid structural elements, flexible seals, smart material actuators, and sometimes electronic components. This multi-material construction requires advanced manufacturing techniques like multi-shot injection molding, ultrasonic welding, and precision adhesive bonding. Each interface between materials represents a potential failure point, requiring rigorous process control. Specifications from manufacturing equipment suppliers indicate that modern multi-component molding systems can achieve the necessary precision with cycle times compatible with mass production. Our manufacturing approach uses modular design that separates complex adaptive elements from basic frame structures, enabling parallel production streams that merge at final assembly, optimizing both quality and production efficiency.

What Quality Control Methods Ensure Consistent Performance?

Traditional quality control focusing on dimensional accuracy is insufficient for adaptive frames, requiring functional testing of the adaptation behavior itself. This typically involves automated test fixtures that simulate facial movements and measure frame response, with each unit undergoing verification before shipment. Statistical process control must monitor not just dimensional parameters but also functional characteristics like actuation force, response time, and cycle durability. Our quality system tests 100% of adaptive frames using automated systems that perform 50+ adaptation cycles while measuring 15 performance parameters, ensuring consistent functionality across production batches despite the inherent variability of smart material behaviors.

Conclusion

Sourcing masks with shape-morphing adaptive frames requires understanding multiple technology approaches, rigorous performance validation methods, and specialized manufacturing considerations. The most successful implementations provide genuine improvements in protection through maintained seal integrity while significantly enhancing wearer comfort through reduced pressure points and personalized fit. As manufacturing capabilities advance and costs decrease, adaptive frame technologies are transitioning from premium innovations to expected features in respiratory protection across healthcare, industrial, and consumer applications.

Ready to explore masks with shape-morphing adaptive frames for your organization or product line? Contact our Business Director, Elaine, at elaine@fumaoclothing.com to discuss how adaptive frame technology can enhance your respiratory protection offerings. Our engineering team has direct experience with multiple adaptive technologies and can help match the right approach to your specific requirements and constraints.