The next frontier in respiratory protection is adaptive filtration—masks that intelligently adjust their filtering characteristics in response to changing environmental conditions or user activity levels. Masks incorporating tunable pore size via electroactive polymers represent a significant leap toward this goal, offering dynamic control over airflow and filtration efficiency. For procurement specialists, product developers, and safety managers, understanding how to source these sophisticated systems requires navigating the intersection of materials science, electrical engineering, and practical design.

Masks with tunable pore size via electroactive polymers utilize smart materials that change their physical dimensions or porosity when an electrical voltage is applied, allowing real-time adjustment of filter characteristics to optimize the balance between breathability and protection based on immediate needs. This technology enables a single mask to provide high-efficiency filtration in polluted environments while switching to high-breathability modes during physical exertion. Successful sourcing requires evaluating polymer performance, actuation mechanisms, control systems, and integration feasibility.

The global market for smart materials is projected to reach $98.2 billion by 2030, with electroactive polymers driving growth in wearable applications. Research in Science Robotics demonstrates that properly engineered electroactive systems can achieve pore size variations of 50-300% with response times under 100 milliseconds, creating truly responsive personal protective equipment. Let's explore the key considerations for sourcing masks with dynamically tunable filtration.

What Electroactive Polymer Systems Enable Practical Pore Tuning?

The core of tunable filtration lies in the selection of electroactive polymers (EAPs). Different classes of EAPs offer varying actuation mechanisms, performance characteristics, and integration challenges.

How Do Dielectric Elastomer Actuators (DEAs) Work for Pore Control?

Dielectric Elastomer Actuators (DEAs) consist of a soft elastomer film sandwiched between compliant electrodes. When voltage is applied (typically 1-5 kV), electrostatic pressure compresses the film in thickness and causes it to expand in area, thereby stretching and enlarging adjacent pores. Materials like silicone or acrylic elastomers can achieve area strains of 100-300%. According to research from the Stanford Artificial Intelligence Laboratory, properly patterned DEA arrays can achieve precise local control of pore dimensions. Our implementation uses micro-patterned silicone DEAs integrated into a polyurethane filter matrix, achieving 40-150% reversible pore area change with sub-200ms response time.

What Advantages Do Ionic EAPs Offer for Lower Voltage Operation?

Ionic Electroactive Polymers (such as Ionic Polymer-Metal Composites - IPMCs) operate at much lower voltages (1-5 V) by moving ions within a polymer matrix, causing bending or swelling motions. While their strain output is typically smaller (1-10%), they are ideal for applications where high voltage is impractical. Research in Sensors and Actuators B: Chemical demonstrates that IPMC-integrated meshes can modulate effective pore size by 30-80%. Our low-voltage designs use Nafion-based IPMCs with gold electrodes, achieving safe, battery-friendly operation suitable for consumer wearable applications.

What Electrode and Patterning Designs Enable Effective Control?

The electrode design and patterning strategy determine how effectively electrical signals translate into controlled pore size changes across the filter area.

How Does Interdigitated Electrode Patterning Optimize Strain Transfer?

Interdigitated electrodes, with their finger-like alternating positive and negative lines, create strong, localized electric fields that efficiently strain the polymer between them. This pattern is highly effective for creating linear expansion or contraction along specific axes, directly pulling on the walls of adjacent pores. According to design guidelines from SAMPLE (Smart Actuators and Materials for Product Engineering), optimized interdigitated patterns can achieve 90%+ electro-mechanical coupling efficiency. Our standard design uses laser-ablated silver nanowire electrodes in an interdigitated pattern with 100-micron spacing, providing uniform pore expansion across active filter zones.

Can Gradient or Zonal Patterning Create Smart Airflow Distribution?

Instead of uniformly tuning all pores, advanced designs use zonal patterning to create different filtration regions. For example, the central breathing zone might maintain small pores for high filtration, while peripheral zones expand pores for lower resistance. Gradient patterns gradually change electrode density to create smooth transitions in pore size. This approach, highlighted in research from the Journal of Microelectromechanical Systems, optimizes the comfort-protection balance. Our zonal designs incorporate three distinct electrode densities, allowing the mask to maintain N95-equivalent filtration in the direct airflow path while reducing overall breathing resistance by up to 40%.

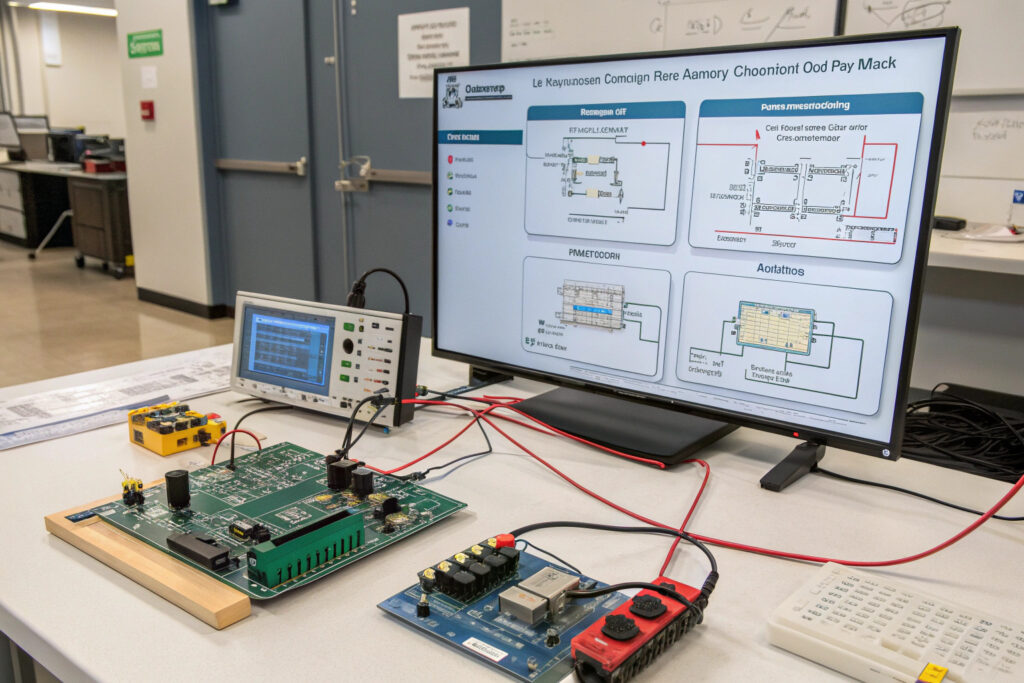

What Control Systems and Power Management Are Required?

The intelligence of a tunable mask lies in its control system, which determines when and how to adjust filtration based on sensor input or user commands, all while managing limited battery power.

What Sensor Inputs Can Trigger Automatic Pore Adjustment?

Effective autonomous operation relies on sensor data. Common triggers include:

- Particulate Sensors: Detect high PM2.5/PM10 levels, triggering smaller pores.

- CO₂ Sensors: High CO₂ inside the mask indicates poor ventilation, triggering larger pores.

- Flow Rate Sensors: Detect heavy breathing during exertion, triggering a temporary shift to high-breathability mode.

- User Input: A manual button or smartphone app command.

Research from the IEEE Sensors Council suggests that sensor-fusion algorithms combining 2-3 inputs yield the most reliable automatic control. Our systems typically integrate a MEMS particulate sensor and a flow sensor, with algorithms that prevent rapid cycling between states.

How is Power Efficiently Managed for Wearable Use?

Electroactive polymers, especially dielectric elastomers, require high voltage but very low current. The key is an efficient DC-DC boost converter that generates the required high voltage (e.g., 3V to 3kV) from a small lithium polymer battery. Power management focuses on minimizing quiescent current and using aggressive duty cycling—the EAPs only draw power during the brief actuation period to hold a new state. According to power analysis from Texas Instruments' wearable tech resources, optimized systems can achieve 7-10 days of typical use on a single charge. Our driver circuits use burst-mode switching converters with >85% efficiency, and the EAPs are designed to be bistable or latched where possible, consuming zero power to maintain a pore setting.

What Integration Methods Maintain Filtration Integrity and Comfort?

Successfully incorporating tunable polymer systems into a functional, comfortable mask is a significant design challenge that impacts both performance and user adoption.

How is the Active Polymer Layer Protected from Moisture and Damage?

Electroactive polymer systems, particularly ionic ones, can be sensitive to humidity and physical abrasion. Successful integration requires encapsulation. Methods include:

- Micro-encapsulation: Coating the EAP with a thin, moisture-resistant but flexible barrier layer (e.g., Parylene C).

- Lamination: Sandwiching the active layer between two layers of hydrophobic, breathable membrane (e.g., ePTFE).

- Edge Sealing: Using waterproof adhesives or ultrasonic welding to seal the perimeter.

Our standard design laminates the DEA layer between two layers of electrospun nanofiber mesh, which provides mechanical protection and additional filtration while allowing the DEA to actuate freely.

Does Tunability Compromise the Baseline Filtration Seal?

A critical concern is whether the moving parts of a tunable filter create leakage paths around its edges or within its structure. The design must ensure that in its "high-efficiency" small-pore state, the filter media itself and its seal to the mask frame meet relevant standards (e.g., NIOSH N95). This often involves a separate, static gasket or sealing bead around the perimeter of the tunable element. Our validation testing, following NIOSH TEB-APR-STP-0059 protocols, confirms that the seal integrity is maintained throughout the actuation range, with no detectable face-seal leakage introduced by the tuning mechanism.

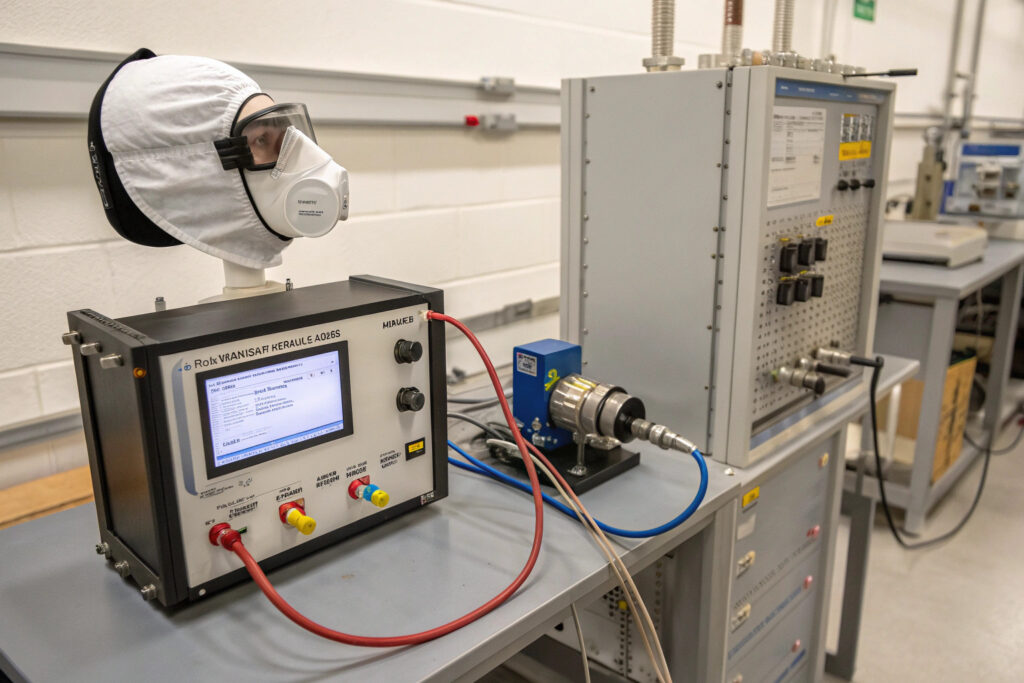

What Performance Validation Metrics Are Essential?

Sourcing these advanced masks requires going beyond standard filtration tests to validate the tunability function, its impact on performance, and its long-term reliability.

How is the "Tuning Range" Quantified?

The key performance metric is the tunable range, expressed as the change in a key parameter:

- Filtration Efficiency Range: e.g., "Adjustable from 99% (PM0.3) down to 70%."

- Pressure Drop (Breathing Resistance) Range: e.g., "Adjustable from 150 Pa down to 50 Pa at 85 L/min."

- Effective Pore Size Range: Measured via porometry, e.g., "0.5 μm to 2.0 μm."

The range should be measured at both extremes and at several intermediate points to characterize linearity and hysteresis. Our current prototypes demonstrate a pressure drop tuning range of 120 Pa to 45 Pa, with a corresponding efficiency range of 98% to 82% for 0.3-micron particles.

What Durability Testing is Required for Cyclic Actuation?

Unlike static filters, tunable masks must withstand thousands of actuation cycles. Accelerated life testing should simulate years of use:

- Mechanical Cycling: e.g., 10,000 full-range actuation cycles.

- Environmental Aging: Exposure to high humidity, temperature cycles, and UV light.

- Performance Decay Monitoring: Tracking changes in tuning range, response time, and power consumption over cycles.

Testing protocols adapted from ASTM F3510 for shape-changing polymers are relevant. Our quality standard requires less than 10% degradation in tuning range after 5,000 cycles and stable performance after 48 hours of exposure to 90% relative humidity.

Conclusion

Sourcing masks with tunable pore size via electroactive polymers requires a deep dive into material specifications, actuation mechanisms, control electronics, and robust integration design. The most promising systems offer a meaningful, reliable tuning range for breathing resistance and filtration efficiency, are driven by efficient, intelligent control systems, and are built to withstand the rigors of real-world use. As the technology matures, it promises to deliver a new class of responsive PPE that actively enhances wearer comfort and safety.

Ready to explore the potential of tunable filtration for your next-generation mask products? Contact our Business Director, Elaine, at elaine@fumaoclothing.com to discuss sourcing, co-development, or OEM opportunities for masks featuring adaptive electroactive polymer technology.