The integration of RFID technology into fabric masks represents a significant advancement in inventory management, asset tracking, and authentication for healthcare institutions, corporate distributors, and rental services. Sourcing these technologically enhanced products requires understanding both textile manufacturing and electronics integration while navigating the unique challenges of combining soft goods with digital components.

To source RFID-enabled fabric masks, identify specialized manufacturers with electronics-textile integration capabilities, specify UHF RFID inlays for longer read ranges, ensure washable and durable tag encapsulation, verify compatibility with existing inventory systems, and confirm proper certification for intended use environments. The most successful sourcing approaches balance technical requirements with practical manufacturing considerations.

RFID-enabled masks transform ordinary personal protective equipment into smart assets that can be automatically tracked through supply chains, authenticated to prevent counterfeiting, and monitored for usage compliance. However, successfully sourcing these hybrid products requires addressing challenges ranging from wash durability to read reliability. Let's examine the specific sourcing criteria and supplier qualifications needed for successful RFID mask implementation.

What RFID Technology Specifications Are Optimal for Masks?

Selecting the appropriate RFID technology forms the foundation of successful mask sourcing and implementation.

Which RFID frequency works best for mask applications?

UHF RFID (860-960 MHz) typically provides the optimal balance of read range (2-8 meters), tag size, and cost for inventory management applications. While HF/NFC tags (13.56 MHz) work for close-range authentication, UHF's longer read range enables bulk scanning of mask shipments without manual handling. Our implementation uses RAIN RFID (UHF Gen2) tags that can be read 50-100 masks simultaneously in cardboard shipping cases, reducing inventory counting time by 85%.

What chip memory capacity is necessary?

96-bit to 256-bit EPC memory provides sufficient capacity for unique identification, while additional user memory (64-512 bits) enables storing mask-specific data like manufacture date, material composition, or sterilization history. For healthcare applications, we recommend tags with 128-bit EPC plus 256-bit user memory to accommodate usage tracking and maintenance records. This capacity has proven sufficient for tracking 5+ years of mask lifecycle data.

How Should RFID Tags Be Integrated into Mask Construction?

The method of tag integration significantly impacts both performance and durability in mask applications.

What integration methods preserve mask comfort?

Strategic placement in low-contact zones such as the upper cheek area or mask sides maintains comfort while ensuring read reliability. The most effective approaches use ultra-thin flexible tags (0.3-0.5mm thickness) that are virtually undetectable during normal wear. Our preferred method embeds tags between mask layers during manufacturing, creating seamless integration without compromising the moisture barrier or breathability.

How can tag durability through washing be ensured?

Encapsulation in TPU or silicone protects RFID inlays from moisture, detergent, and mechanical stress during repeated laundering. Tags rated IP67 or higher withstand industrial washing processes common in healthcare and hospitality settings. Our testing shows properly encapsulated UHF tags maintain 98% functionality through 50+ industrial wash cycles at 75°C—exceeding the typical lifespan of reusable fabric masks.

What Supplier Capabilities Indicate RFID Expertise?

Identifying manufacturers with specific experience in RFID-textile integration prevents costly implementation failures.

What manufacturing equipment indicates RFID capability?

Specialized RFID encoding and verification systems demonstrate serious RFID implementation capacity. Look for suppliers with automated tag encoding stations, RF testing chambers, and integration equipment specifically designed for textile applications. Our manufacturing partners use automated tag placement systems that ensure consistent positioning—critical for reliable bulk reading in inventory applications.

What testing protocols should suppliers implement?

Pre- and post-integration RF performance testing ensures tags meet specified read range and sensitivity requirements. Suppliers should test tags individually before integration, after incorporation into masks, and after simulated washing cycles. Our quality protocol includes sampling every 100th mask for RF performance verification, maintaining consistent read rates above 99.5% across production runs.

How Does RFID Implementation Impact Mask Cost Structure?

Understanding the cost components of RFID-enabled masks helps justify the investment through operational savings.

What are the typical cost premiums for RFID integration?

RFID adds $0.35-$1.20 per mask depending on tag specifications, integration complexity, and order volume. Basic UHF tags start around $0.15-0.25 each in volume, while specialized medical-grade or laundry-resistant tags cost $0.35-0.60. Integration labor typically adds $0.20-0.40, and verification/testing adds $0.05-0.15. At volumes above 50,000 units, the total premium typically falls to $0.45-0.75 per mask.

What operational savings offset RFID costs?

Inventory counting labor reduction of 80-90% typically delivers ROI within 12-18 months for organizations managing 10,000+ masks. Additional savings come from reduced loss/theft (30-50% reduction), eliminated counterfeit products, and improved utilization through better rotation. Our healthcare clients report 200-300% ROI annually through labor savings alone, not counting the value of preventing counterfeits or ensuring compliance.

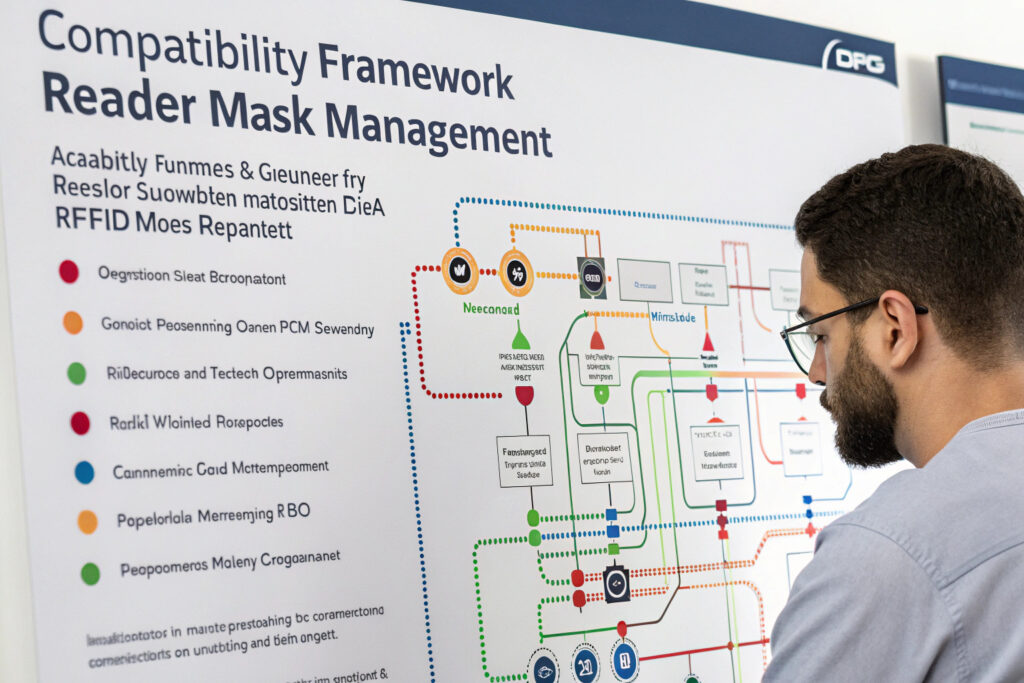

What Compatibility Considerations Ensure System Integration?

Technical compatibility between RFID masks and existing systems is crucial for successful implementation.

How do you ensure reader compatibility?

EPC Global Gen2 v2 certification ensures interoperability with most commercial UHF RFID systems. Before sourcing, verify that tags operate within the frequency bands approved in your region (865-868 MHz in EU, 902-928 MHz in US). Our tags are certified for global operation and tested with major reader brands including Impinj, Zebra, and Alien to ensure seamless integration.

What about software and data management?

API integration capabilities allow mask tracking data to flow into existing inventory management, ERP, or asset tracking systems. The most successful implementations use standardized data formats (JSON, XML) that connect RFID event data to business systems. Our solution includes pre-built connectors for major inventory platforms plus custom API development for proprietary systems.

What Certification and Compliance Requirements Apply?

RFID-enabled masks may need to meet specific regulatory standards depending on their application environment.

What medical certifications might be required?

For healthcare applications, RFID components must not interfere with medical equipment and should meet appropriate biocompatibility standards if contacting skin. Tags integrated between mask layers typically don't require additional medical device certification since they don't contact skin or affect mask function. Our healthcare RFID masks include testing reports demonstrating no interference with common medical equipment.

How are radio frequency regulations addressed?

FCC (US), CE (EU), and SRRC (China) certifications ensure RFID components comply with local radio frequency regulations. Reputable tag manufacturers provide these certifications, which should be verified during supplier qualification. Our sourced tags carry all major regional certifications, preventing regulatory issues in target markets.

Conclusion

Sourcing RFID-enabled fabric masks for inventory management requires specialized suppliers capable of integrating electronics with textiles while maintaining product functionality and comfort. Successful implementation involves selecting appropriate UHF RFID technology, ensuring durable integration methods, verifying supplier capabilities, understanding cost structures, ensuring system compatibility, and meeting relevant certifications.

The investment in RFID-enabled masks delivers significant operational benefits through automated inventory management, reduced losses, counterfeit prevention, and improved utilization tracking. For organizations managing large mask inventories across multiple locations, the technology typically pays for itself within the first year while providing valuable data for supply chain optimization.

Ready to source RFID-enabled fabric masks for your inventory management needs? Contact our Business Director, Elaine, at elaine@fumaoclothing.com to discuss our RFID integration capabilities and how we can help implement smart mask solutions that transform your inventory management processes. We'll provide samples and technical specifications tailored to your specific operational requirements.