With "antimicrobial" now stamped across countless fabric mask listings, how can serious buyers like Ron separate fact from fiction? In an industry driven by both innovation and marketing buzzwords, verifying these claims is not just a matter of trust—it’s a matter of compliance and customer safety.

The most reliable way to verify antimicrobial claims in fabric masks is through a combination of certified lab testing (e.g., ISO 20743, AATCC 100), chemical safety declarations, and transparent sourcing from known treatment providers. Always demand evidence—not just promises.

In this article, I’ll explain how to verify treated fabric claims step by step, which documents to request, and how to detect red flags in supplier behavior.

What Testing Standards Confirm Anti-Microbial Performance?

What Lab Tests Are Industry Standard?

Two major international standards are used to validate antimicrobial efficacy in textiles:

- ISO 20743 (Textiles — Determination of antibacterial activity of textile products)

- AATCC 100 (Antibacterial Finishes on Textile Materials Test Method)

These tests measure bacterial reduction (commonly Staphylococcus aureus and Klebsiella pneumoniae) on treated vs untreated fabric after 24 hours. Results show the log reduction rate—e.g., 99.9% = 3-log reduction.

Leading global labs like SGS, Intertek, and Bureau Veritas are certified to issue these reports.

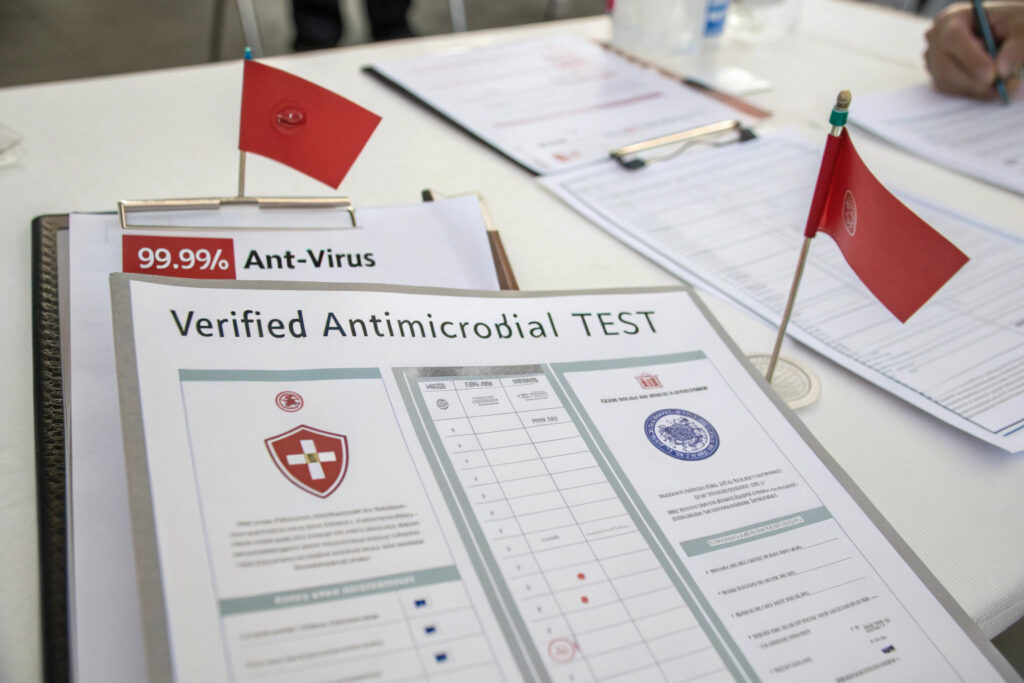

How Do I Know a Lab Report Is Real?

Look for the following elements:

| Element | Why It Matters |

|---|---|

| Lab Logo & Accreditation | Confirms authority (e.g., ISO 17025) |

| Test Method | Should state ISO 20743 or AATCC 100 |

| Batch/Fabric ID | Must match your order details |

| Reduction % & Log Value | 99.9% or higher is considered effective |

Also verify if the report date is recent (within 12 months). Outdated tests may not apply to the current fabric lot.

You can directly validate lab-issued certificates using their online portals or QR verification.

What Anti-Microbial Chemicals Are Safe and Regulated?

What Are the Most Common Safe Treatments?

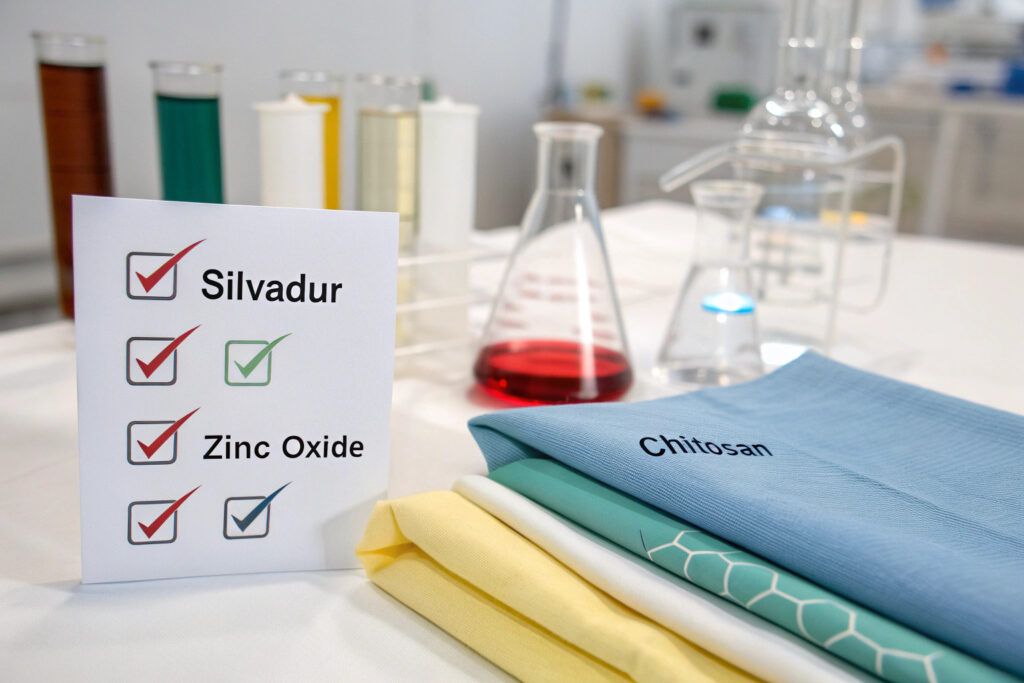

Here are top formulations that pass regulatory safety and performance tests:

| Chemical/Treatment | Features | Brand Examples |

|---|---|---|

| Silver Ions | Anti-bacterial, odor neutralizing | Silvadur™, HeiQ Viroblock |

| Zinc Oxide | Natural, breathable, UV-blocking | HealthGuard™ ZP |

| Chitosan | Derived from shellfish, eco-safe | Novaron™, Kitozyme |

| Quats (limited use) | Strong but sometimes allergenic | Must be certified |

Always request the Safety Data Sheet (SDS) and application method—coating, impregnation, or embedded yarn.

Reference EPA Registered Antimicrobials and REACH Annexes for global legality.

Should These Treatments Be Declared on Export Docs?

Yes. If a treated fabric is declared as antimicrobial on labels or customs paperwork, it must include:

- Treatment brand name and type

- Concentration or finishing %

- Declaration of compliance (EU BPR, US EPA, etc.)

Failure to include this may result in customs issues, especially in the U.S. or EU. Your supplier should provide a Treatment Declaration Letter listing applied chemicals and usage scope.

How Can You Spot False or Exaggerated Claims?

What Are the Red Flags in Supplier Claims?

Beware of:

- Claims like “Kills all viruses” or “Anti-COVID” without supporting science

- Photoshopped or cropped lab reports

- Absence of treatment name or test report details

- Confusing “anti-bacterial” with “anti-odor” or “anti-dust”

Many small traders copy images or documents from other suppliers. Ask them to include your company or product name in the report. Or better—pay for a third-party pre-shipment test with labs like TÜV SÜD.

Is OEKO-TEX Enough?

Not for antimicrobial claims. OEKO-TEX Standard 100 only certifies safety from harmful chemicals—it doesn’t validate antibacterial function.

Always combine OEKO-TEX with performance tests like ISO 20743 or AATCC 100 to cover both safety and functionality.

Check OEKO-TEX Label Check to validate any certificate shared with you.

How Do You Ensure Consistency in Bulk Production?

Can Treatment Performance Degrade in Mass Runs?

Yes. Some treatments can be applied unevenly if machinery isn’t calibrated. Others wash out after several cleaning cycles.

At Global-Caps, we batch-test every production lot and attach a QR code to each carton. Buyers can scan and access:

- Lot-specific ISO reports

- Treatment chemical breakdown

- Fabric supplier details

- Washing durability data

We also include wash tests (up to 20 cycles) as part of verification for long-term clients. You can request video documentation or a testing walkthrough via video call.

Use resources like AATCC.org to learn how repeatable these tests are and what results to expect.

Should You Add Random Third-Party Tests?

Yes—especially on first orders. Many buyers ask SGS or Intertek to test 10 randomly picked units from the finished batch. This small cost ensures credibility.

You can include this clause in your PO or quality checklist. It shows the supplier you’re serious about claims and compliance.

Conclusion

The fabric mask market is flooded with antimicrobial promises—but not all are created equal. Buyers like Ron need clear proof, certified reports, and batch-level consistency to ensure what’s marketed matches what’s delivered.

By verifying claims through ISO 20743 or AATCC 100 tests, requesting safety data on treatments, and demanding batch tracking with declarations, you can ensure you’re delivering truly functional and safe products to your customers.

At Global-Caps, we’ve built our systems for exactly that kind of transparency. Because in a world full of claims, proof sells—and trust keeps clients coming back.