Many global buyers feel anxious about EU import compliance. The worry is real: what if a shipment of fabric face coverings gets stopped at customs because it does not meet REACH or CE requirements? That delay can cause losses and even damage a brand’s reputation. I have faced this in the past when shipping to the U.S., and I know how painful it is to handle unexpected non-compliance.

The solution is clear. To verify compliance for Europe, you must ensure that masks are tested for REACH-restricted substances and, if applicable, certified under CE marking for either PPE or medical device rules. With the right documentation and process, you can confidently export to Europe without fearing penalties or rejections.

This guide explains the full process: how to verify REACH compliance, how to check CE requirements, how to confirm certificates are legitimate, and what documentation to prepare.

How to verify REACH compliance for fabric masks?

Many suppliers ignore chemical testing until customs stops their products. That is the problem—hidden chemicals in dyes or coatings can lead to serious fines. The agitation is simple: non-compliant goods cannot be sold in Europe, and shipments may be destroyed. The solution is direct: verify REACH compliance before exporting.

To verify REACH compliance, fabric masks must be tested by accredited third-party labs to confirm they do not contain Substances of Very High Concern (SVHCs) above 0.1% weight. This includes azo dyes, phthalates, heavy metals, or PFAS. Test reports should be included in the technical file, and documentation should be available for EU authorities on request.

Ignoring REACH rules risks financial loss. By contrast, following a step-by-step verification process gives buyers confidence and makes exports much smoother.

Why is REACH important for fabric masks?

REACH is Europe’s most comprehensive regulation on chemicals. Any textile item, including masks, must comply before entering the EU market. Non-compliance means products cannot be imported. According to QIMA’s textile compliance guide, SVHC substances like lead, chromium VI, or formaldehyde must be below set thresholds. Also, Chemical Industry Journal highlights how PPE and textiles are regularly monitored at customs for REACH standards.

Even if masks look harmless, untreated dyes or coatings may hide toxic materials. Importers are legally responsible for ensuring compliance. That is why lab verification is essential.

How to test and document REACH compliance?

Manufacturers should use independent, accredited labs to run tests for restricted substances. For instance, Luonto’s compliance blog explains how certified reports confirm compliance. Also, EU authorities recommend third-party testing over supplier self-declarations.

Once testing is complete, the data—including batch numbers and results—must be stored in the technical file. Buyers should request these documents before finalizing purchase orders. As QIMA stresses, proof of compliance is as valuable as the product itself when exporting to Europe.

How to verify CE compliance for fabric face coverings?

Some exporters think the CE mark is only a label, but it is a legal guarantee. Fake certificates are common, and customs can confiscate entire shipments if CE compliance is not real.

To verify CE compliance, first determine whether your fabric face covering falls under PPE (EU Regulation 2016/425) or medical devices (EN 14683). Then, prepare a Declaration of Conformity and technical file. If the product is PPE, testing and approval by an EU-listed notified body is mandatory.

This process ensures your masks legally enter the European market and are trusted by buyers.

What is the CE marking process for masks?

CE marking shows that a product meets EU rules on safety, health, and environment. According to European Commission guidance, only regulated products require CE. For masks, the key question is whether they are medical (EN 14683) or PPE (EN 149).

Medical masks (Class I) often allow self-certification, as FORCE Technology explains. However, protective masks used as PPE need notified body approval.

How to prepare the CE technical file?

The CE technical file should include design drawings, risk assessments, lab test results, instructions, and the signed Declaration of Conformity. According to I3C Global, notified bodies must be checked via the EU’s NANDO database.

Each CE certificate must be verified for authenticity. As VerifyFull explains, only certificates with a valid four-digit notified body number are legally recognized.

How to check legitimacy of CE certificates and notified bodies?

Fraudulent CE papers are a big risk in global trade. A fake certificate may look real but is useless during inspections.

The safe way is to confirm the notified body in the EU NANDO database, ensuring the number matches and the scope covers PPE or medical devices. Many brokers issue misleading papers, but only NANDO-listed bodies are valid.

Why should you distrust uncertified suppliers?

Suppliers sometimes issue fake CE files to close deals quickly. But customs cross-check certificates with official databases. Wikipedia and European Commission both note that only notified bodies with EU registration are legitimate.

If a supplier refuses to provide valid technical files, that is a red flag. Buying from them risks seizure of goods at customs.

How to confirm authenticity step by step?

First, locate the notified body’s four-digit code on the CE certificate. Then search that code in the official NANDO EU database. Finally, confirm the scope matches your product category, such as PPE or medical devices. NPEO outlines these steps to avoid fraud.

What documents must be kept for export?

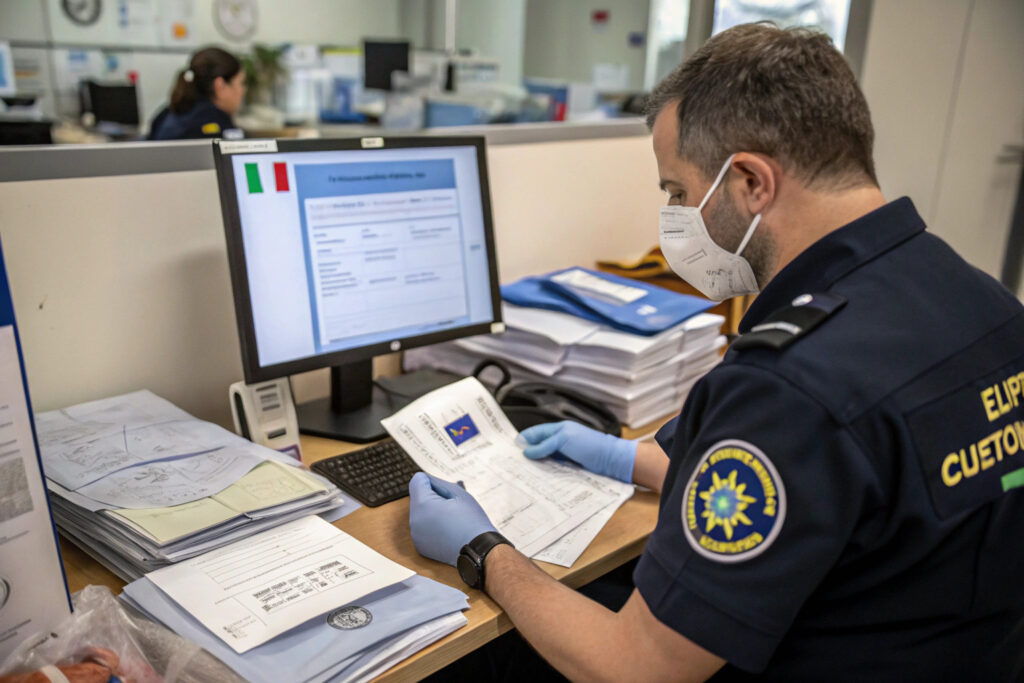

The documents you keep are just as critical as the masks themselves. Customs often check paperwork first.

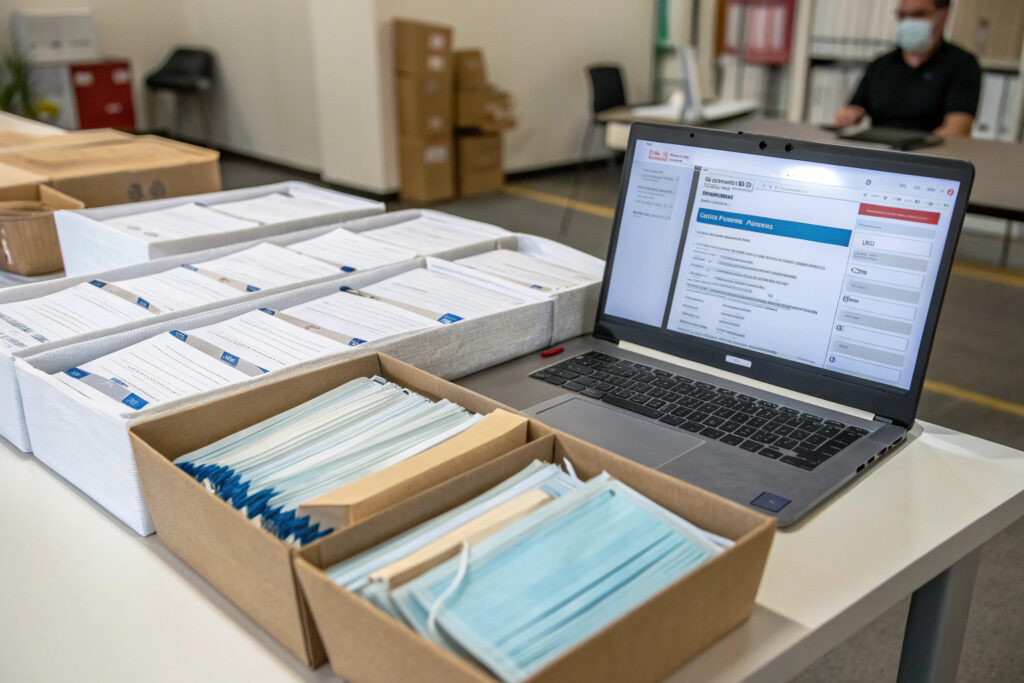

For REACH and CE compliance, you must maintain a full technical file with test reports, Declaration of Conformity, product specifications, and batch traceability for at least 10 years.

Without these files, even compliant products may face clearance delays.

Which compliance documents are mandatory?

At minimum, exporters need:

- REACH test reports proving no restricted substances

- Declaration of Conformity for CE marking

- Product user instructions

- Batch numbers and traceability records

As BestForWorld explains, EU customs check these papers before approving release.

How long should documents be kept?

According to European Commission, exporters must keep CE documentation for at least 10 years. Force Technology also stresses that all technical files should be available upon request during audits.

Conclusion

Verifying REACH and CE compliance is not optional—it is the backbone of successful exports to Europe. Testing for restricted substances, preparing CE technical files, checking notified body legitimacy, and keeping documents ready will protect your business from costly delays and build confidence with European buyers.

If you want a reliable partner for fabric face covering production and compliance support, contact us at Shanghai Fumao. Our Business Director Elaine is available at elaine@fumaoclothing.com to discuss how we can co-create compliant, market-ready products for your business.