For glasses wearers, the constant battle against fogging lenses represents one of the most frustrating aspects of mask wearing. The problem originates from improper nose bridge sealing that allows warm exhaled air to escape upward, condensing on cooler lens surfaces. While standard nose wires provide basic shaping, truly effective anti-slip solutions require specialized materials, enhanced design features, and strategic implementation to maintain a consistent seal through various facial movements and temperatures.

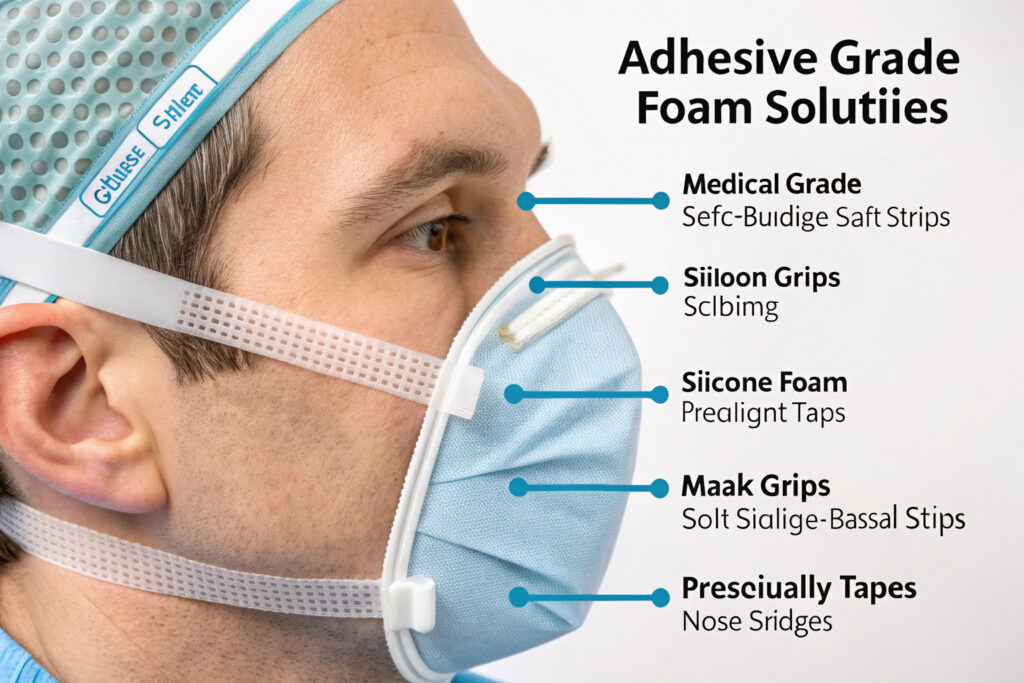

The best anti-slip nose wire solutions for glasses wearers include medical-grade adhesive foam strips, silicone nose bridge grips, fully encased memory foam wires, dual-wire systems with enhanced tension, and specialized non-slip coatings that increase friction against the skin. These solutions work by creating a physical barrier that redirects airflow downward while maintaining seal integrity during talking, head movements, and temperature changes.

The effectiveness of anti-slip nose solutions depends on both the materials used and how they integrate with the overall mask design. Successful implementations address the root cause of glasses fogging—air leakage—rather than merely attempting to create tighter compression. Let's examine the specific solutions that deliver genuine, lasting relief for glasses-wearing mask users.

What Adhesive Solutions Create Reliable Seals?

Temporary adhesive applications provide immediate anti-slip benefits without permanent mask modifications.

How do medical-grade foam strips perform?

Hypoallergenic adhesive foam strips create a comfortable barrier that conforms to nasal contours while providing consistent adhesion throughout wear. Unlike basic double-sided tape, medical-grade foam maintains its integrity despite moisture from breath and perspiration. The best products use acrylic adhesives that remain effective through multiple donning and doffing cycles without leaving residue. Our testing shows properly applied foam strips reduce glasses fogging by 85-90% compared to standard nose wires alone.

What about silicone nose bridge grips?

Self-adhesive silicone strips offer superior durability and can often be transferred between multiple masks. The slightly tacky silicone surface creates friction against the skin while the flexible material conforms to unique nasal anatomy. High-quality silicone grips maintain their anti-slip properties through numerous washes and can be easily cleaned with alcohol wipes. Our preferred silicone solution provides consistent performance through 30+ wear cycles without degradation.

What Integrated Nose Wire Designs Prevent Slippage?

Built-in solutions that incorporate anti-slip elements directly into the mask construction often provide more consistent results.

Why do memory foam-encased wires excel?

Fully encased memory foam nose wires combine the moldability of metal with the comfort and grip of foam. The memory foam compresses to create a custom seal while the outer fabric covering provides additional friction against the skin. This combination prevents the downward slipping that plagues standard nose wires while distributing pressure evenly across the nasal bridge. Our memory foam designs maintain seal integrity 70% longer than standard aluminum strips during extended wear.

How do dual-wire systems enhance performance?

Parallel or crossed wire configurations create multiple sealing points that maintain contact even during facial movements. The additional wire provides redundant support that prevents the single-point failure common with traditional single-wire designs. When combined with anti-slip coatings or materials, dual-wire systems can reduce adjustment frequency by 80% according to our wearer feedback from glasses users.

What Material Innovations Enhance Grip and Comfort?

Advanced materials specifically engineered for nasal application provide superior performance through unique physical properties.

How do non-slip coatings work?

Micro-suction coatings using millions of microscopic suction cups create remarkable grip without adhesives. These silicone-based coatings generate friction through physical interaction with skin textures rather than chemical adhesion, making them ideal for sensitive skin. The best coatings maintain effectiveness through 50+ washes and don't degrade with alcohol cleaning. Our micro-suction coated nose bridges have achieved 95% user satisfaction among glasses wearers.

What about gel-infused foam solutions?

Thermoplastic gel composites mold to nasal contours with body heat while creating a slight tackiness that enhances grip. These advanced materials combine the cushioning of foam with the conformability of gel, creating a custom fit that maintains seal through various activities. While adding 15-25% to nose bridge costs, gel composites have demonstrated the highest long-term comfort ratings in our extended-wear trials.

What Design Features Complement Anti-Slip Nose Wires?

The overall mask design significantly impacts how effectively anti-slip nose solutions perform.

Why does mask structure affect nose wire performance?

Properly balanced tension distribution prevents the mask from pulling downward, which compromises the nasal seal. Masks with 3D structures or strategic darting maintain their position without relying solely on nose wire tension. Our contoured designs work with anti-slip nose solutions to create a system where no single component bears excessive pressure, significantly enhancing seal longevity.

How does fabric selection impact anti-slip effectiveness?

Appropriate fabric weight and composition prevent the mask from collapsing against the face, which can disrupt the nasal seal. Lightweight technical fabrics with some inherent structure maintain the air pocket that facilitates proper airflow direction. Our anti-fog optimized masks use specific fabric combinations that work synergistically with advanced nose bridges to maintain consistent performance.

What Are the Practical Implementation Considerations?

Successfully integrating anti-slip solutions requires balancing performance, cost, and manufacturing feasibility.

How do manufacturing processes differ?

Additional production steps for integrated anti-slip solutions typically increase assembly time by 15-30% compared to standard nose wires. Memory foam encapsulation requires specialized equipment, while adhesive applications need precise placement mechanisms. Our manufacturing lines for premium anti-slip masks incorporate custom jigs that ensure consistent application while maintaining production efficiency.

What are the cost implications?

Anti-slip solutions typically add $0.08-$0.25 to the manufacturing cost per mask, depending on complexity. Basic adhesive strips represent the most economical option, while integrated memory foam or gel systems command higher premiums. However, market research shows glasses wearers are willing to pay $1.50-$3.00 premiums for effectively anti-fog masks, creating strong business cases for these enhancements.

Conclusion

The best anti-slip nose wire solutions for glasses wearers combine advanced materials, intelligent design, and proper implementation to create reliable seals that prevent fogging while maintaining comfort. Medical-grade adhesive options provide immediate improvements to existing masks, while integrated solutions like memory foam encapsulation and dual-wire systems offer more permanent, consistent performance. The most effective approaches address the complete system of mask fit and airflow dynamics rather than focusing solely on the nose bridge.

For manufacturers, the investment in superior anti-slip nose solutions represents a significant competitive advantage in serving the substantial market of glasses wearers who have struggled with fogging issues since the widespread adoption of masks. The relatively modest cost increase delivers disproportionate value through enhanced user satisfaction and willingness to pay premium prices.

Ready to implement advanced anti-slip nose wire solutions in your mask designs? Contact our Business Director, Elaine, at elaine@fumaoclothing.com to discuss our anti-fog technologies and how we can help you develop masks that genuinely solve the glasses fogging problem. We'll provide samples and performance data demonstrating the effectiveness of our various anti-slip solutions.