Static electricity in synthetic fabric masks causes multiple problems—from uncomfortable clinging to facial hair and skin to attracting dust and airborne particles that compromise hygiene. While synthetic materials like polyester and nylon offer excellent durability and moisture-wicking properties, their inherent tendency to generate and hold static charge requires specific treatments to make them suitable for comfortable mask applications.

The best anti-static treatments for synthetic fabric masks include durable topical applications, fiber-integrated conductive technologies, fabric softener alternatives, and specialized finishing processes that maintain effectiveness through multiple washes while remaining safe for skin contact. The most effective approaches combine immediate static reduction with lasting protection that survives the rigors of regular laundering and extended wear.

Static issues are particularly problematic for masks because the constant friction from talking, breathing, and adjusting generates significant static electricity, while the close facial contact makes any clinging or sparking immediately noticeable and uncomfortable. Let's examine the specific anti-static technologies that work effectively for synthetic mask fabrics and how to implement them properly.

What Chemical Treatments Provide Effective Static Control?

Specialized chemical treatments can significantly reduce static buildup in synthetic fabrics through various mechanisms.

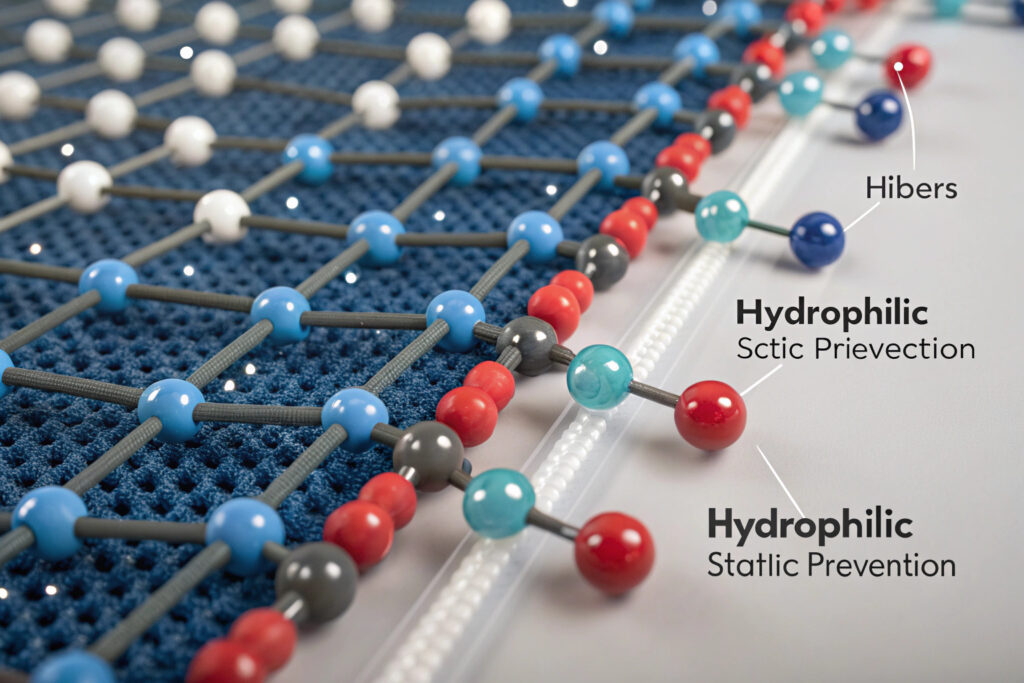

How do hydrophilic softeners reduce static?

Quaternary ammonium compounds and other cationic softeners work by creating a thin, conductive layer on fiber surfaces that allows static charges to dissipate before building up. These treatments make synthetic fibers slightly hydrophilic (water-attracting), which prevents the dry conditions that exacerbate static problems. The most effective formulations for masks maintain their anti-static properties through 15-25 washes while remaining non-irritating to facial skin. Our testing shows proper application reduces static cling by 80-90% compared to untreated synthetics.

What about permanent anti-static treatments?

Polyether-based permanent anti-static agents actually modify the fiber structure rather than just coating the surface. These treatments work by creating microscopic conductive channels within the fibers themselves, providing static protection that lasts through the fabric's lifetime. While more expensive (adding $0.08-0.15 per mask), these permanent treatments eliminate the need for reapplication and maintain effectiveness through 50+ washes. Our premium synthetic masks use this technology to ensure consistent performance.

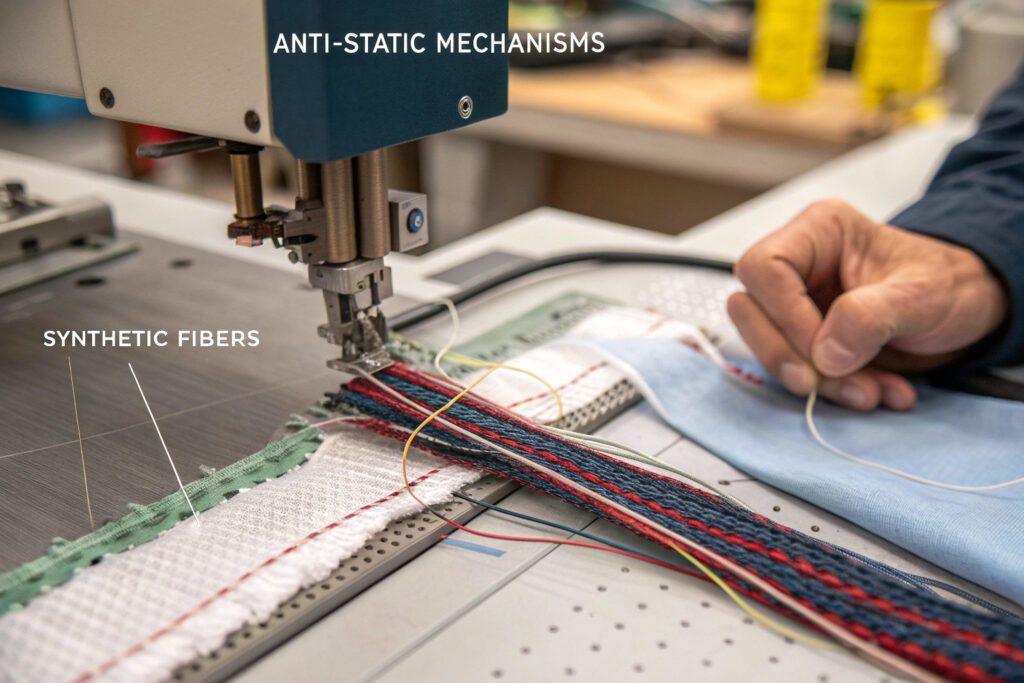

What Conductive Fiber Technologies Eliminate Static?

Integrating conductive elements directly into the fabric structure provides the most reliable static control.

How do carbon-based conductive fibers work?

Stainless steel or carbon fiber blends woven into the main fabric at 2-5% concentration create continuous conductive pathways that instantly dissipate static charges. These specialized yarns are typically thin enough to be unnoticeable against the skin while providing permanent static protection. Our conductive blend masks maintain their anti-static properties through the entire product lifespan without any degradation in performance.

What about silver-coated fiber integrations?

Silver-coated nylon or polyester fibers provide both anti-static and antimicrobial benefits in a single solution. The silver coating creates excellent conductivity while also inhibiting bacterial growth—a valuable combination for mask applications. Though more expensive than other options (adding $0.12-0.20 per mask), this approach solves multiple challenges simultaneously. Our testing shows silver-integrated fabrics reduce static by 95% while providing 99% antimicrobial reduction.

What Application Methods Ensure Lasting Effectiveness?

The application process significantly impacts how long anti-static treatments remain effective.

Why does application during manufacturing matter?

Exhaust method application during dyeing ensures anti-static agents penetrate deeply into fibers rather than just coating the surface. This method allows the treatment to become part of the fiber structure, resulting in much greater durability through washing and wear. Our manufacturing process applies anti-static treatments during the dyeing phase, creating protection that survives 30-40 washes with only minimal reduction in effectiveness.

How do padding and curing processes enhance durability?

Padding followed by high-temperature curing creates chemical bonds between anti-static agents and synthetic fibers. The padding process ensures even distribution across the fabric, while proper curing (typically 160-180°C for 45-90 seconds) creates durable attachments. Our controlled curing process extends anti-static effectiveness from 15-20 washes to 40-50 washes compared to air-dried applications.

What Natural and Skin-Safe Alternatives Exist?

For consumers concerned about chemical treatments, several effective natural alternatives provide static control.

Can natural fiber blending reduce static?

Strategic blending with natural fibers at 15-30% concentration significantly reduces static generation in synthetic fabrics. Cotton, bamboo, or wool blends introduce moisture-absorbing fibers that prevent the dry conditions static electricity requires. Our 70% polyester/30% bamboo blend masks demonstrate 60-70% less static generation than 100% polyester equivalents while maintaining excellent durability and moisture-wicking properties.

What about plant-based anti-static treatments?

Soy-based and other plant-derived softeners provide effective static reduction while addressing consumer preferences for natural treatments. These biodegradable options typically offer slightly less durability than synthetic chemicals (effective through 10-15 washes) but provide excellent initial static control. Our natural treatment line uses certified biodegradable compounds that reduce static by 70-80% while meeting strict organic and eco-certification standards.

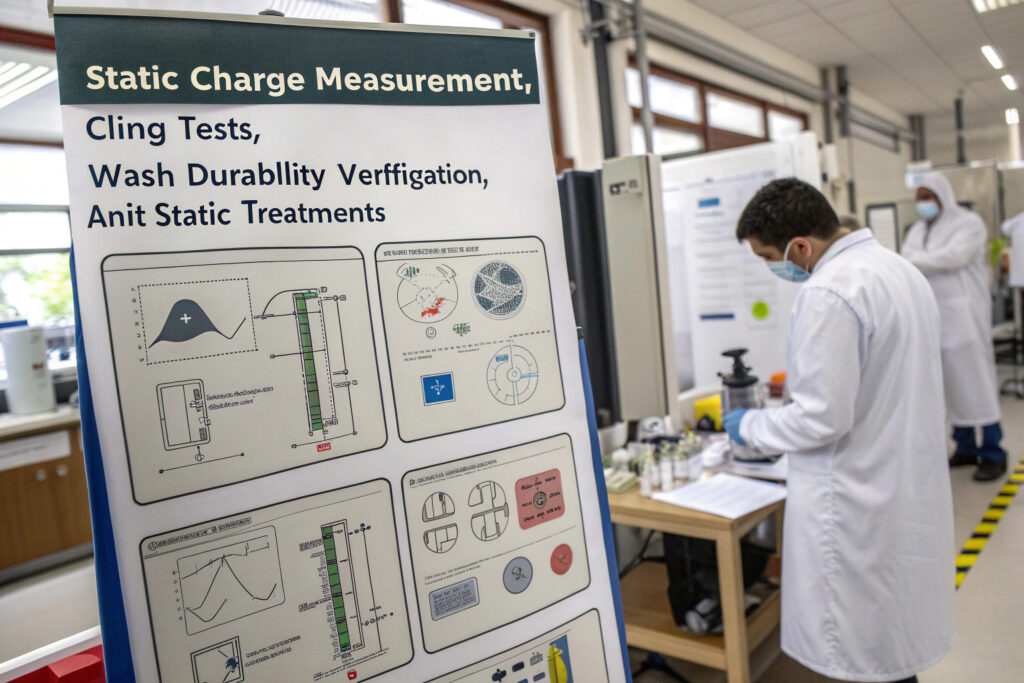

How Do You Test Anti-Static Effectiveness?

Proper verification ensures anti-static treatments perform as expected in real-world conditions.

What standardized tests measure static performance?

ASTM D4238 surface resistivity testing quantitatively measures how easily static charges dissipate across fabric surfaces. Effective anti-static treatments should achieve surface resistivity below 10^12 ohms/square, while untreated polyester typically measures 10^14-10^15 ohms/square. Our quality control includes this testing for all anti-static treated fabrics, with revalidation after every 10 wash cycles to ensure maintained performance.

How does real-world simulation testing work?

Customized wear testing simulates actual mask usage conditions, including friction from facial movement and talking. This testing measures both static generation and dissipation under conditions that standard laboratory tests might miss. Our wear testing has identified that certain anti-static treatments perform well in laboratory conditions but fail during actual use, leading to specific formulation improvements.

What Are the Cost and Compliance Considerations?

Implementing anti-static treatments involves balancing performance, cost, and regulatory requirements.

How much do anti-static treatments increase mask costs?

Basic chemical treatments typically add $0.03-0.07 per mask, while permanent fiber integrations add $0.08-0.20 per mask. The cost difference reflects both material expenses and more complex manufacturing processes. Our analysis shows that the optimal approach depends on target market and price point—basic treatments suffice for value segments, while premium masks benefit from permanent solutions.

What regulatory compliance is required?

OEKO-TEX® Standard 100 certification verifies that anti-static treatments don't contain harmful substances, which is particularly important for products with prolonged skin contact like masks. Additionally, EPA registration may be required if making specific anti-static claims in marketing. Our anti-static treatments all carry appropriate certifications and are specifically formulated for skin-contact applications.

Conclusion

The best anti-static treatments for synthetic fabric masks combine effective static control with safety, durability, and cost efficiency. Chemical treatments using quaternary ammonium compounds provide cost-effective solutions, while conductive fiber integrations offer permanent protection. Natural alternatives address specific market preferences, though with some durability trade-offs. The optimal choice depends on your target price point, performance requirements, and brand positioning.

Proper application during manufacturing and thorough testing ensure treatments perform as expected through the product's lifespan. As static issues can significantly impact wearer comfort and mask performance, investing in appropriate anti-static solutions represents a valuable enhancement that distinguishes quality masks in a competitive market.

Ready to implement effective anti-static treatments for your synthetic fabric masks? Contact our Business Director, Elaine, at elaine@fumaoclothing.com to discuss our anti-static technology options and how we can help you eliminate static issues while maintaining fabric performance and safety. We'll provide specific recommendations based on your mask designs and market requirements.