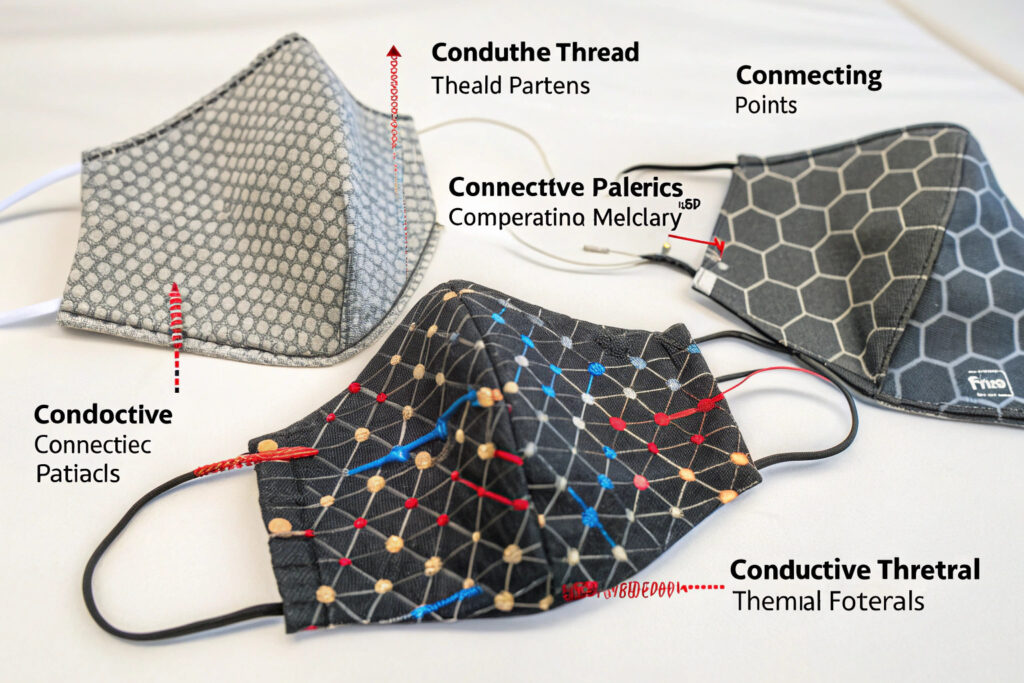

Integrating heating elements into fabric masks requires specialized conductive threads that can safely carry electrical current while maintaining flexibility, comfort, and durability. The selection of appropriate conductive thread is critical for both performance and safety in heated mask systems, balancing electrical properties with textile compatibility and user comfort.

The best conductive thread options for heated mask systems include silver-coated polyamide threads, stainless steel filament blends, carbon-based conductive yarns, and hybrid metal-polymer composites, each offering different advantages for resistance heating, durability, and manufacturing compatibility. The optimal choice depends on your specific heating requirements, power source limitations, and manufacturing capabilities.

Heated mask systems present unique challenges compared to other wearable electronics—they require consistent low-temperature heating across facial contours, must maintain functionality through flexing and moisture exposure, and absolutely cannot overheat or create safety hazards. The conductive thread serves as both the heating element and the integration method, making material selection crucial for successful product development. Let's examine the specific conductive thread options and their applications in heated mask systems.

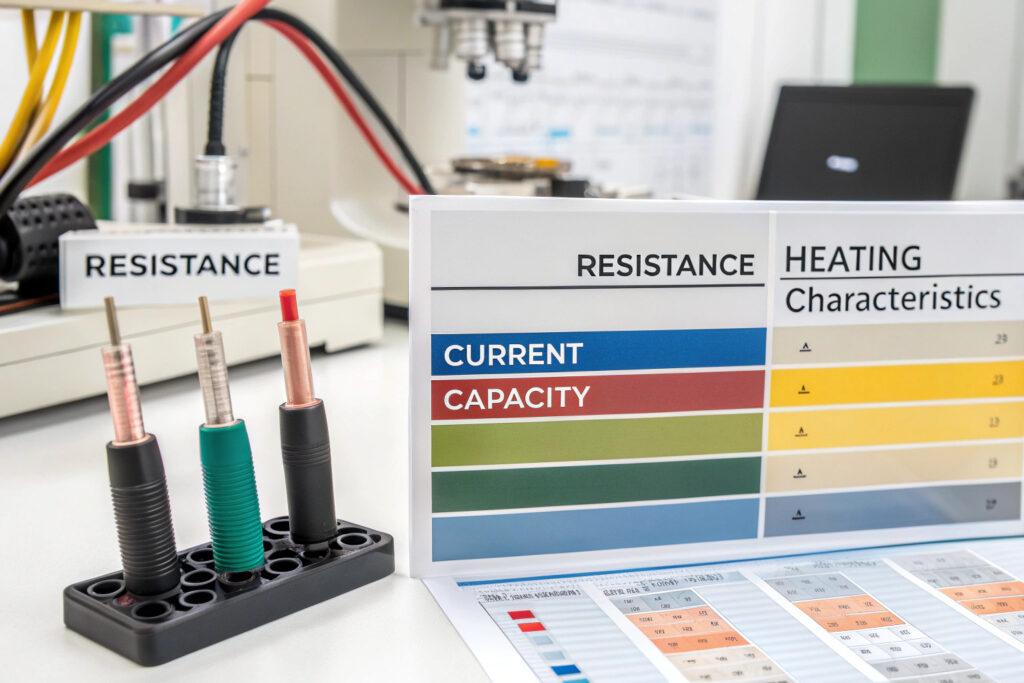

What Electrical Properties Define Suitable Conductive Threads?

The fundamental electrical characteristics determine whether a conductive thread can function effectively and safely as a heating element in mask applications.

How does resistance affect heating performance?

Lower resistance threads (0.1-5 Ω/m) generate more heat at lower voltages but require careful current management to prevent overheating. Higher resistance threads (10-100 Ω/m) distribute heat more evenly and are safer for battery-powered applications but may require higher voltages. For mask applications targeting 35-45°C surface temperatures, threads with 15-40 Ω/m resistance typically work well with 3.7-7.4V power sources. Our testing shows that silver-coated threads in the 20-30 Ω/m range provide the most consistent heating for facial applications.

What about current capacity and safety?

Ampacity ratings determine how much current a thread can safely carry without overheating or degrading. Most conductive threads for wearable applications can safely handle 0.1-0.5A continuously, sufficient for gentle heating applications. Threads must maintain stable resistance when flexed, stretched, or exposed to moisture—critical factors for mask applications. Our safety protocols include testing threads at 150% of expected operating current to ensure margin for unexpected conditions.

What Material Options Offer the Best Performance?

Different conductive materials offer varying balances of electrical performance, durability, and manufacturing compatibility.

Why are silver-coated polyamide threads popular?

Silver-coated polyamide threads offer excellent conductivity (0.5-5 Ω/m) with good flexibility and textile compatibility. The silver coating provides high conductivity while the polyamide core maintains strength and flexibility. These threads can be sewn using standard equipment and withstand repeated washing, making them ideal for reusable heated masks. However, silver can tarnish over time, potentially increasing resistance. Our accelerated aging tests show properly encapsulated silver threads maintain stable resistance through 50+ heating cycles.

When are stainless steel threads preferable?

Stainless steel filament threads provide superior durability and consistent resistance but are less flexible and more challenging to work with. Their higher resistance (20-100 Ω/m) makes them suitable for distributed heating applications where even heat distribution is prioritized over maximum temperature. Stainless steel maintains its properties when exposed to moisture and doesn't corrode, making it ideal for masks that may be cleaned frequently. Our medical-grade heated masks use stainless steel threads for their predictable performance and biocompatibility.

What Construction Methods Ensure Effective Heating?

How conductive threads are integrated into masks significantly impacts both heating performance and user comfort.

What stitching patterns optimize heat distribution?

Serpentine or meander patterns create longer heating paths that distribute heat evenly across larger areas, preventing hot spots. The spacing between parallel runs (typically 5-15mm) determines heat distribution density—closer spacing for higher heat concentration, wider spacing for gentle warming. Our optimized patterns achieve temperature variations of less than ±2°C across the mask surface, ensuring consistent comfort.

How can thermal isolation enhance efficiency?

Strategic insulation placement behind heating elements directs warmth toward the face while reducing power requirements. Thin, breathable reflective layers can improve thermal efficiency by 30-40% without significantly increasing mask bulk or reducing breathability. Our most efficient designs use micro-perforated radiant barriers that maintain airflow while reflecting infrared energy toward the skin.

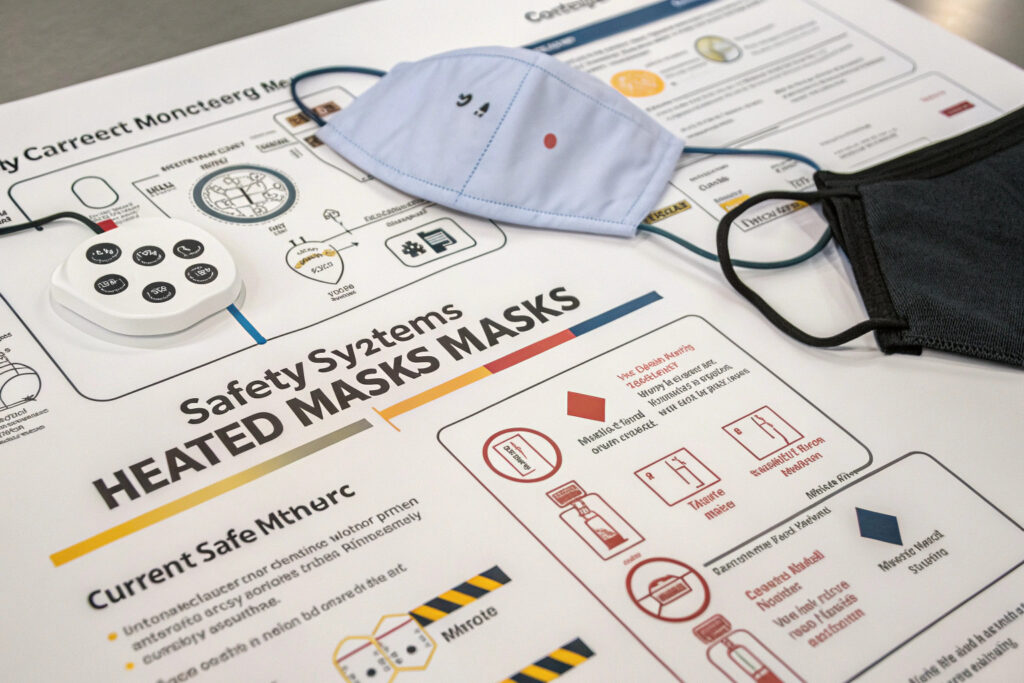

What Safety Considerations Are Paramount?

Heated wearable systems require rigorous safety protocols, particularly for products worn on the face.

How is temperature regulation achieved?

Integrated thermistors or NTC sensors monitor temperature at multiple points, allowing the control circuit to adjust power delivery to maintain safe, comfortable temperatures. The best systems include redundant sensors and software limits that prevent temperatures from exceeding 50°C even if primary controls fail. Our safety systems incorporate both hardware current limiting and software temperature monitoring with automatic shutdown at 48°C.

What electrical isolation prevents user risk?

Proper insulation and grounding ensure users never contact active electrical components. Conductive threads must be completely encapsulated within non-conductive layers, with all connections properly insulated. Our designs use multilayer fabric construction with the heating elements sandwiched between insulating layers, with additional edge sealing to prevent moisture ingress that could create short circuits.

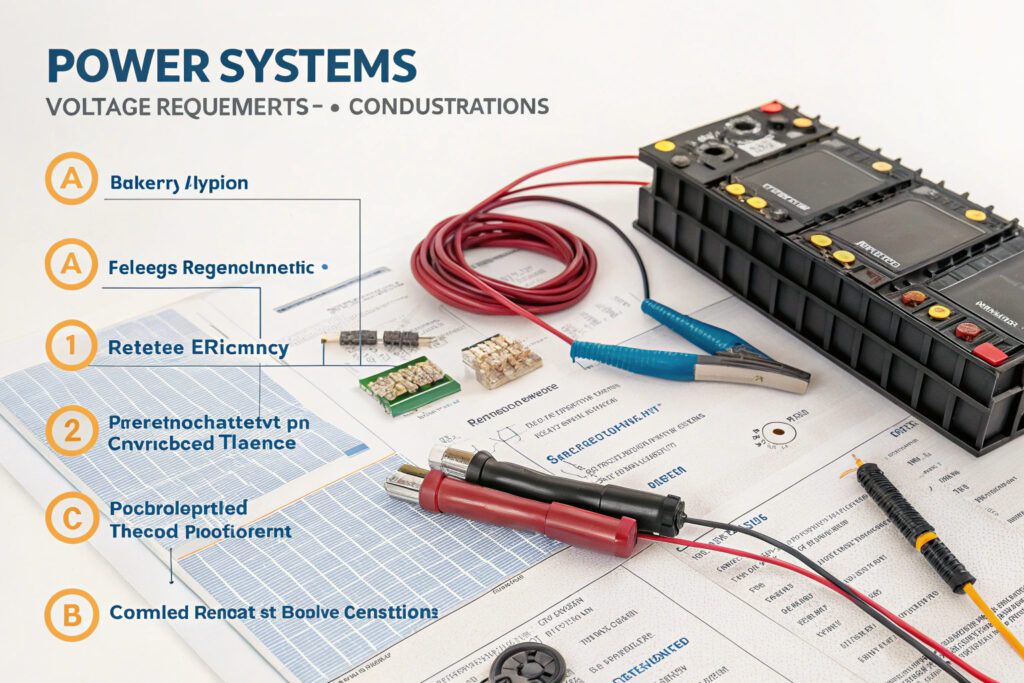

What Power Systems Work with Conductive Thread Heaters?

The power source selection directly influences the conductive thread choice and heating system design.

What battery capacities support practical runtime?

Lithium polymer batteries in the 500-1500mAh range typically provide 2-8 hours of continuous heating depending on thread resistance and desired temperature. Higher resistance threads (30-60 Ω/m) are more efficient for battery operation, while lower resistance threads may require larger batteries for practical runtime. Our balanced designs provide 4-6 hours of continuous heating at 38-42°C from an 800mAh battery.

How does voltage affect thread selection?

Lower voltage systems (3.7-5V) are safer but require lower resistance threads or more complex power management to achieve sufficient heating. Higher voltage systems (7.4-12V) work better with higher resistance threads but introduce additional safety considerations. Most of our consumer heated masks operate at 5V USB power or 7.4V from two Li-ion cells, balancing safety with performance.

What Manufacturing Considerations Impact Production?

The practical aspects of manufacturing with conductive threads influence both design choices and production costs.

What specialized equipment is needed?

Standard sewing machines with modified tension systems can typically handle most conductive threads, though some stainless steel or thick hybrid threads may require industrial machines. The key challenge is maintaining consistent thread tension to ensure uniform electrical resistance throughout the heating pattern. Our production lines use computerized sewing machines with optical sensors that verify stitch quality and detect potential short circuits during manufacturing.

How does conductive thread impact production costs?

Material costs for conductive threads are significantly higher than standard threads—typically $2-15 per meter compared to $0.05-0.20 for standard threads. Additionally, the specialized processes for integration and testing add 25-40% to manufacturing labor costs. However, the finished product can command substantial price premiums—our heated masks typically retail at 3-5x the price of standard masks, justifying the additional manufacturing complexity.

Conclusion

The best conductive thread options for heated mask systems balance electrical performance, safety, durability, and manufacturing practicality. Silver-coated polyamide threads offer the best combination of conductivity and ease of use for most applications, while stainless steel threads provide superior durability for medical or high-reliability applications. Carbon-based threads offer interesting possibilities for lower-temperature applications where flexibility is paramount.

Successful implementation requires careful attention to heating pattern design, power management, safety systems, and manufacturing processes. The most effective heated mask systems treat the conductive thread as part of an integrated system rather than simply a component, optimizing the entire design for safety, comfort, and performance.

Ready to develop heated mask systems with optimal conductive thread selection? Contact our Business Director, Elaine, at elaine@fumaoclothing.com to discuss our experience with conductive textiles and heated wearable systems. We'll help you select the right materials and design approaches for your specific heated mask application.