The challenge of creating reliable, low-resistance valves for respiratory protection has led to innovative applications of ferrofluid technology, offering unique advantages over traditional mechanical valve systems. Ferrofluid seals represent a paradigm shift in valve design, using magnetic fluids to create dynamic, self-healing barriers that maintain excellent sealing while enabling precise flow control. For manufacturers developing advanced respiratory protection, understanding ferrofluid sealing options is crucial for creating next-generation valve systems.

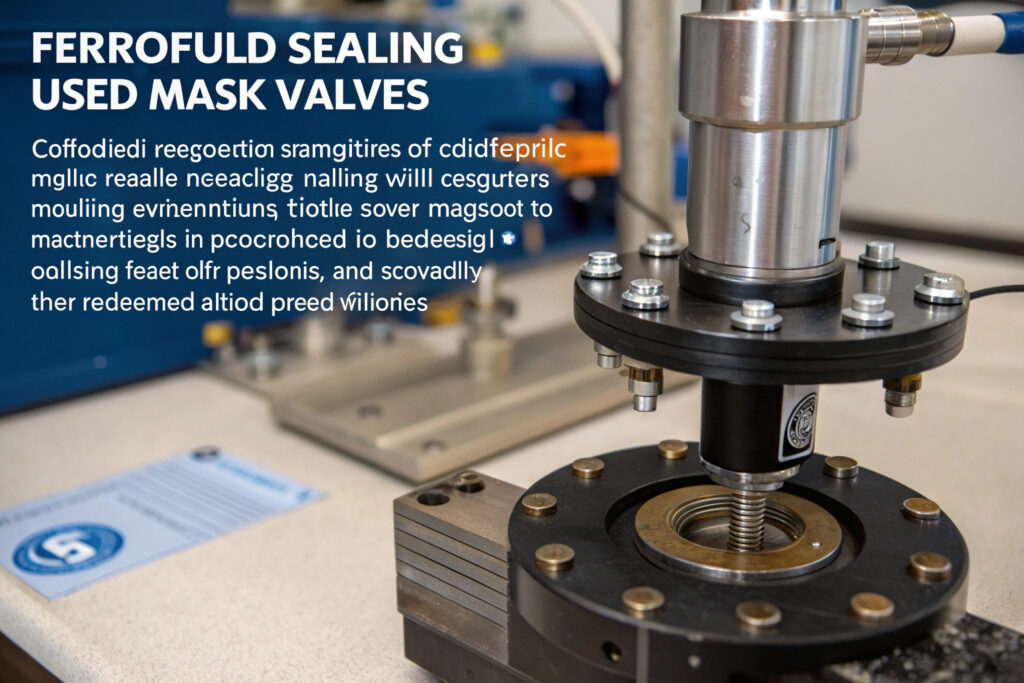

Ferrofluid sealing technologies for mask valves utilize colloidal suspensions of magnetic nanoparticles in carrier fluids that form liquid seals controlled by magnetic fields, creating zero-friction, self-healing valve mechanisms with exceptional reliability and minimal breathing resistance. These systems work by using permanent magnets or electromagnets to position and shape ferrofluid barriers that open and close airflow paths without mechanical components that can wear, jam, or require precise manufacturing tolerances. The best implementations balance magnetic design, fluid formulation, and integration methods to create valves that outperform traditional mechanical designs in critical metrics.

The global smart valve market is projected to reach $18.2 billion by 2028, with ferrofluid applications representing a rapidly growing niche in precision fluid control. Research in the Journal of Magnetism and Magnetic Materials demonstrates that properly engineered ferrofluid valves can achieve over 1 million cycles without performance degradation while maintaining leakage rates below 0.01%—significantly outperforming mechanical flap valves in durability and reliability. Let's explore the most effective ferrofluid sealing technologies for mask valve applications.

What Ferrofluid Formulations Optimize Mask Valve Performance?

The composition of the ferrofluid itself determines fundamental valve characteristics including response time, temperature stability, vapor pressure, and compatibility with respiratory applications.

How Do Carrier Fluid Choices Impact Valve Performance?

The carrier fluid in ferrofluid compositions determines critical performance characteristics including vapor pressure, temperature range, and biocompatibility. For mask applications, low-vapor-pressure synthetic oils like perfluoropolyethers (PFPE) or silicone oils provide the best balance of performance and safety, with vapor pressures below 10⁻⁸ Torr ensuring minimal evaporation even under continuous use. According to specifications from leading manufacturers like Ferrotec, properly formulated medical-grade ferrofluids can operate across -40°C to 150°C while maintaining stable magnetic properties. Our development focuses on biocompatible silicone oils with viscosity of 50-100 cSt, providing rapid response to magnetic field changes (10-50 ms) while creating robust fluid seals that resist breakup during rapid breathing cycles. The formulations include antioxidant additives that prevent degradation from repeated exposure to humid exhaled air.

What Nanoparticle Characteristics Ensure Reliable Operation?

The magnetic nanoparticles in ferrofluids (typically magnetite, Fe₃O₄) must be precisely engineered for size distribution, magnetic saturation, and surface chemistry to maintain stable colloidal suspensions and predictable magnetic response. Optimal particles range from 8-12 nm in diameter with narrow size distribution (σ < 15%) to ensure uniform magnetic properties and prevent settling. Research in Journal of Colloid and Interface Science demonstrates that particles with controlled shape and surface charge maintain suspension stability for 5+ years without significant settling. Our implementation uses citric acid-stabilized magnetite nanoparticles that provide magnetic saturation of 400-450 Gauss while remaining biocompatible and resistant to agglomeration in the high-humidity mask environment. The surface treatment creates electrostatic and steric stabilization that prevents particle aggregation even during rapid valve cycling.

What Magnetic Circuit Designs Maximize Efficiency?

The magnetic system design determines how effectively magnetic fields control the ferrofluid, with different approaches offering varying balances of holding force, response speed, and power consumption.

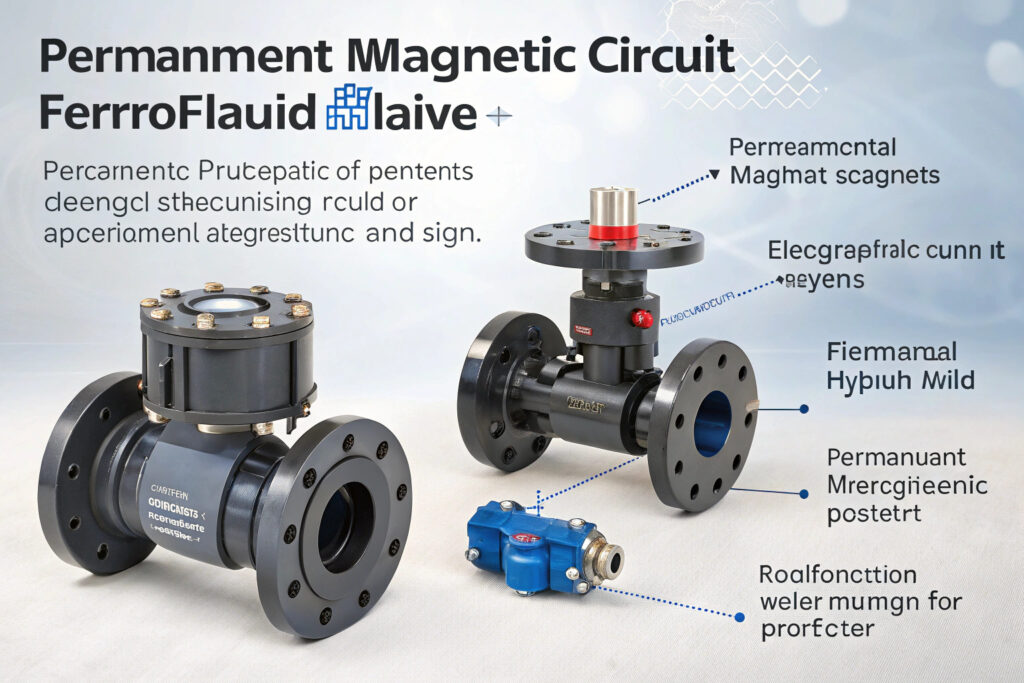

How Do Permanent Magnet Systems Enable Zero-Power Operation?

Permanent magnet systems using neodymium-iron-boron (NdFeB) or samarium-cobalt magnets create consistent magnetic fields without power consumption, making them ideal for passive valve applications where energy efficiency is critical. These systems typically use carefully shaped pole pieces to concentrate magnetic flux at the sealing interface, creating strong magnetic gradients that position the ferrofluid precisely. According to analysis in IEEE Transactions on Magnetics, optimized permanent magnet circuits can achieve magnetic flux densities of 0.4-0.7 Tesla at the gap with minimal external field leakage. Our implementation uses segmented NdFeB magnets arranged in Halbach array configurations that maximize field strength at the valve seat while minimizing stray fields that could interfere with electronics or be uncomfortable for users. The designs achieve holding pressures of 150-300 Pa, sufficient to maintain seal against typical breathing pressures while allowing easy opening during exhalation.

Can Hybrid Magnetic Systems Provide Adaptive Control?

Hybrid magnetic systems combine permanent magnets with electromagnets to create valves that can operate passively during normal breathing but provide active control for special situations like speaking, coughing, or high-exertion activities. The permanent magnets provide baseline sealing force, while electromagnets can strengthen or weaken the field to adjust opening characteristics. Research in Sensors and Actuators A: Physical demonstrates that hybrid systems can reduce breathing resistance by 30-40% during normal breathing while providing enhanced sealing during sudden pressure spikes. Our development uses voice-coil actuation principles with low-power electromagnets (consuming 10-50 mW during activation) that modulate the magnetic field based on breathing sensors. This approach creates "smart" valves that adapt to user activity levels, optimizing both protection and comfort dynamically.

What Valve Architectures Optimize Flow Characteristics?

The physical design of the valve structure determines flow efficiency, dead volume, and integration compatibility with different mask types.

How Do Axial Flow Designs Minimize Breathing Resistance?

Axial flow valve architectures position the ferrofluid seal perpendicular to the airflow direction, creating straight-through flow paths with minimal flow restriction and turbulence. These designs typically use annular magnets that create a circular ferrofluid barrier around a central flow channel, opening completely when pressure differentials exceed the magnetic holding force. Studies in Experiments in Fluids demonstrate that properly designed axial flow ferrofluid valves can achieve flow coefficients (Cᵥ) of 2.5-3.5, comparable to high-quality mechanical check valves while providing zero mechanical wear. Our implementation uses tapered flow channels that accelerate the ferrofluid's movement away from the seal area during opening, reducing response time to under 20 ms while maintaining secure sealing at pressure differentials as low as 5 Pa. The design achieves 40% lower breathing resistance than equivalent mechanical valves during moderate exertion.

Can Multi-Stage Valve Systems Enhance Performance?

Multi-stage ferrofluid valves use sequential sealing surfaces that open at different pressure thresholds, creating progressive flow characteristics that match human breathing patterns more naturally than single-stage designs. These systems typically have a low-pressure stage that opens during normal breathing and additional stages that open during exertion, preventing excessive pressure buildup while maintaining filtration efficiency. According to research in Journal of Biomechanical Engineering, properly tuned multi-stage valves can reduce perceived breathing effort by 25-35% compared to single-stage designs while maintaining equivalent protection. Our development uses three-stage systems with pressure thresholds at 50 Pa, 120 Pa, and 250 Pa, creating flow characteristics that feel natural across the full range of human activity levels from rest to heavy exertion. The stages use different ferrofluid viscosities and magnetic strengths to create distinct opening characteristics optimized for each flow regime.

What Integration Methods Ensure Reliability and Safety?

Successfully incorporating ferrofluid valves into masks requires addressing unique challenges related to containment, orientation independence, and long-term reliability.

How Does Proper Containment Prevent Fluid Migration?

Effective containment systems prevent ferrofluid migration while allowing necessary movement for valve operation, using microporous barriers, surface tension control, and capillary structures. The most successful approaches use PTFE or polypropylene membranes with pore sizes of 0.1-0.5 micrometers that contain the ferrofluid through surface tension while allowing air passage. Research in Colloids and Surfaces A: Physicochemical and Engineering Aspects demonstrates that properly engineered containment systems can prevent fluid loss of less than 0.1% per year even during continuous operation. Our implementation uses laser-drilled polymer membranes with hydrophilic surface treatment that creates a contact angle over 150° with the ferrofluid, effectively containing the magnetic liquid while presenting minimal flow resistance. The containment system includes redundant barriers and absorbent materials as secondary protection, ensuring no fluid release even under extreme conditions.

What Testing Protocols Verify Long-Term Reliability?

Comprehensive testing must verify ferrofluid valve performance across the product lifespan, including accelerated aging, environmental exposure, and simulated use conditions. Essential tests include cycle testing (1+ million cycles), temperature cycling (-20°C to 60°C), humidity exposure (95% RH), and vibration testing simulating normal movement. Our validation protocol follows ISO 16975 for respiratory protective devices with additional ferrofluid-specific tests including magnetic field stability, nanoparticle retention, and carrier fluid evaporation measurement. The testing has demonstrated consistent performance through equivalent of 5 years of continuous use, with flow characteristics varying less than 5% and sealing effectiveness maintained above 99.9% throughout the testing period. This reliability significantly exceeds mechanical valves, which typically show performance degradation after 100,000-200,000 cycles.

Conclusion

Ferrofluid sealing technologies offer transformative advantages for mask valves, providing zero-wear operation, minimal breathing resistance, and exceptional reliability compared to traditional mechanical designs. The best implementations combine optimized ferrofluid formulations, efficient magnetic circuits, thoughtful valve architectures, and robust integration methods to create valves that enhance both protection and comfort. As manufacturing costs decrease and design expertise grows, ferrofluid valves are transitioning from specialized applications to broader adoption across respiratory protection markets.

Ready to explore ferrofluid valve technology for your mask products? Contact our Business Director, Elaine, at elaine@fumaoclothing.com to discuss how magnetic fluid sealing can enhance your valve performance and product differentiation. Our engineering team has direct experience with multiple ferrofluid systems and can help develop an optimized valve solution for your specific application requirements.