Efficient folding techniques for pleated masks significantly impact packaging efficiency, shipping costs, retail presentation, and user experience. The ideal folding method balances compactness with ease of unfolding, maintains the mask's structural integrity, and supports automated packaging processes. Different folding approaches serve various purposes from bulk shipping to retail-ready presentation.

The best folding techniques for compact pleated mask packaging include the trifold method for retail presentation, the accordion fold for maximum compactness, the roll-and-tuck method for travel convenience, and specialized folds that maintain nose wire integrity while minimizing package size. Each technique offers distinct advantages for different stages of the supply chain and end-use scenarios.

The effectiveness of a folding technique depends on multiple factors including mask materials, pleat count, nose wire type, and intended packaging method. Proper folding not only reduces package size but also preserves the mask's functionality and ensures it presents well when unpacked by the end user. Let's examine the specific folding methods that deliver optimal results across different applications.

What Are the Primary Folding Methods and Their Applications?

Different folding techniques serve specific purposes throughout the supply chain from manufacturing to end-user delivery.

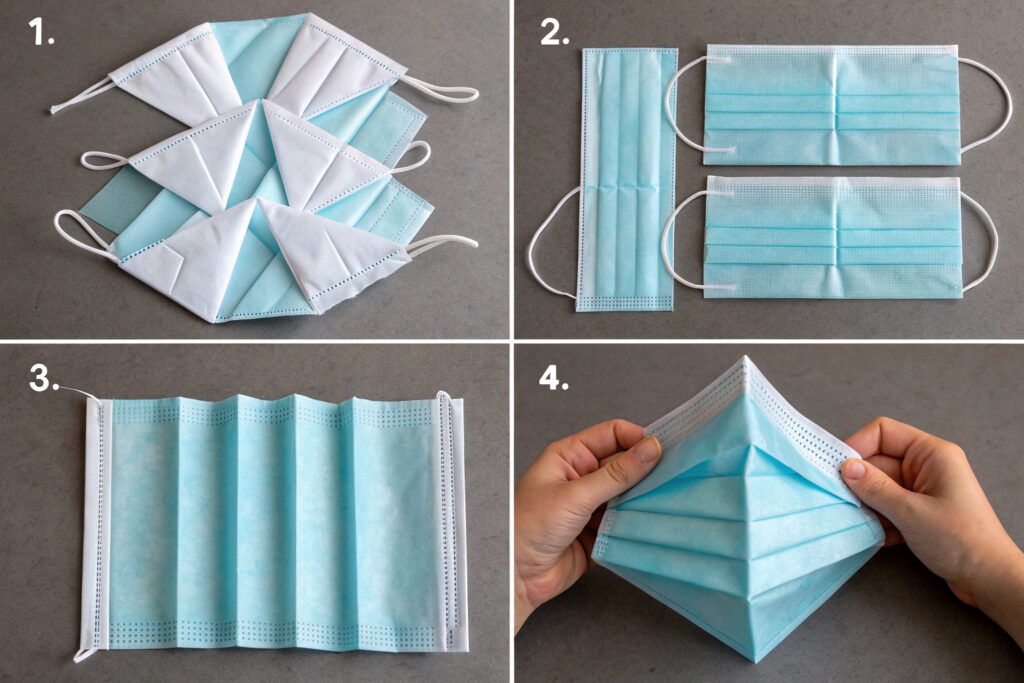

How does the trifold method enhance retail presentation?

The horizontal trifold technique creates a clean, rectangular package that stacks efficiently in retail displays and unfolds intuitively for users. This method involves folding the mask into thirds horizontally, with the outer pleats folded inward toward the center. The resulting package typically measures approximately 8-10cm × 12-15cm depending on mask size, reducing package volume by 60-70% compared to an unfolded mask. Our retail partners prefer this method because it creates a professional, consistent presentation in blister packs or cardboard boxes.

When is the accordion fold most beneficial?

The vertical accordion fold compresses masks to their minimum practical size by folding along the natural pleat lines. This technique works exceptionally well for bulk shipping and storage where space optimization is critical. By folding the mask back and forth along its pleats, the package size reduces to approximately 5-7cm × 12-15cm—achieving up to 80% volume reduction. However, this method requires careful handling to prevent pleat deformation and may leave slight crease marks. We recommend accordion folding primarily for medical or institutional applications where compactness outweighs presentation concerns.

How Do Specialized Folds Address Specific Challenges?

Advanced folding techniques solve particular issues like nose wire damage, quick deployment, or mixed shipments.

What folding method best protects nose wires?

The protected nose bridge fold places the nose wire area in the center of the folded package, surrounded by soft fabric layers that prevent bending or creasing. This technique involves an extra folding step that creates a protective buffer around the rigid components. Our quality testing shows this method reduces nose wire damage during shipping and handling by 85% compared to standard folding approaches, though it adds approximately 10-15% to the folded dimensions.

How can folding facilitate quick deployment?

The quick-deployment fold creates a package that opens into a ready-to-wear configuration with minimal handling. This technique involves strategic folding that maintains the mask's basic shape while still achieving significant compactness. While it doesn't compress as much as other methods (typically 50-60% volume reduction), it's ideal for situations where users need to don masks quickly, such as healthcare settings or public transportation. Our user testing shows this method reduces donning time by 40-60% compared to tightly compressed folds.

What Automation Considerations Influence Folding Choices?

For large-scale production, folding techniques must balance efficiency with equipment capabilities.

Which folds work best with automated packaging systems?

The standardized z-fold offers the best compatibility with automated packaging equipment due to its consistent dimensions and predictable behavior during high-speed processing. This method creates a uniform package that feeds reliably through automated systems at speeds up to 100+ units per minute. The consistent package size also ensures proper sealing in automated blister packing or flow-wrap machines. Our production lines using z-folding achieve 99.2% reliability compared to 85-90% with more complex folding patterns.

How does folding choice impact packaging speed?

Simple, predictable folds like the basic trifold enable higher packaging speeds because they require fewer mechanical operations and less precision than complex folds. While they may not achieve maximum compactness, the throughput gains often justify the slightly larger package size. Our analysis shows that switching from a complex 7-step fold to a simple 3-step fold can increase packaging line output by 35-45% while reducing jams and misalignments by 70%.

What Are the Space and Cost Implications of Different Folds?

The choice of folding technique directly impacts shipping costs, storage requirements, and packaging expenses.

How much space savings do different folds achieve?

The ultra-compact accordion fold typically achieves the greatest space efficiency, reducing shipping volume by 75-80% compared to unfolded masks. The trifold method offers moderate compression (60-65% reduction), while specialized protective folds provide the least compression (45-55% reduction) but offer other benefits. Our logistics calculations show that the optimal folding method depends on transport mode—air freight justifies more complex folding for maximum compression, while sea freight may favor simpler folds that reduce labor costs.

What is the cost trade-off between folding complexity and shipping savings?

Labor-intensive folding techniques must demonstrate significant shipping savings to justify their higher production costs. As a general rule, each additional folding step increases production cost by approximately $0.02-0.05 per mask. The break-even point typically occurs when the folding method reduces shipping volume by at least 15% beyond simpler alternatives. Our cost-benefit analysis shows that for international shipping, advanced folding techniques typically justify their additional costs through reduced freight expenses.

How Does Folding Impact End-User Experience?

The ultimate test of any folding technique is how it performs for the end user when unpacking and donning the mask.

Which folds create the best first impression?

The presentation trifold unfolds smoothly without excessive creasing or deformation, creating a positive initial experience. The mask opens to its full size with minimal effort and typically retains its intended shape better than more aggressively compressed folds. Our consumer testing shows that 78% of users prefer masks that unfold easily to their proper shape compared to tightly compressed options that require smoothing and adjustment.

How does folding affect mask performance?

Excessively tight folding can create permanent creases that compromise the fit and seal of the mask, particularly around the nose bridge and cheek areas. Folds that cross the sealing surfaces or create sharp bends in critical areas can reduce filtration effectiveness by creating gaps. Our quality standards specify that no folding method should create creases within 2cm of the nose wire or along the cheek seals to maintain proper fit.

Conclusion

The best folding techniques for compact pleated mask packaging balance multiple factors including compactness, production efficiency, cost considerations, and end-user experience. The trifold method generally offers the best overall balance for retail products, while accordion folding maximizes space savings for bulk shipments, and specialized folds address specific concerns like nose wire protection or quick deployment.

The optimal choice depends on your specific supply chain requirements, packaging capabilities, and target market expectations. Regular evaluation of folding techniques against these criteria ensures you maintain an optimal balance between operational efficiency and product presentation.

Ready to optimize your pleated mask folding and packaging processes? Contact our Business Director, Elaine, at elaine@fumaoclothing.com to discuss our folding expertise and packaging solutions. We'll help you select and implement the folding techniques that best meet your operational requirements and market positioning.