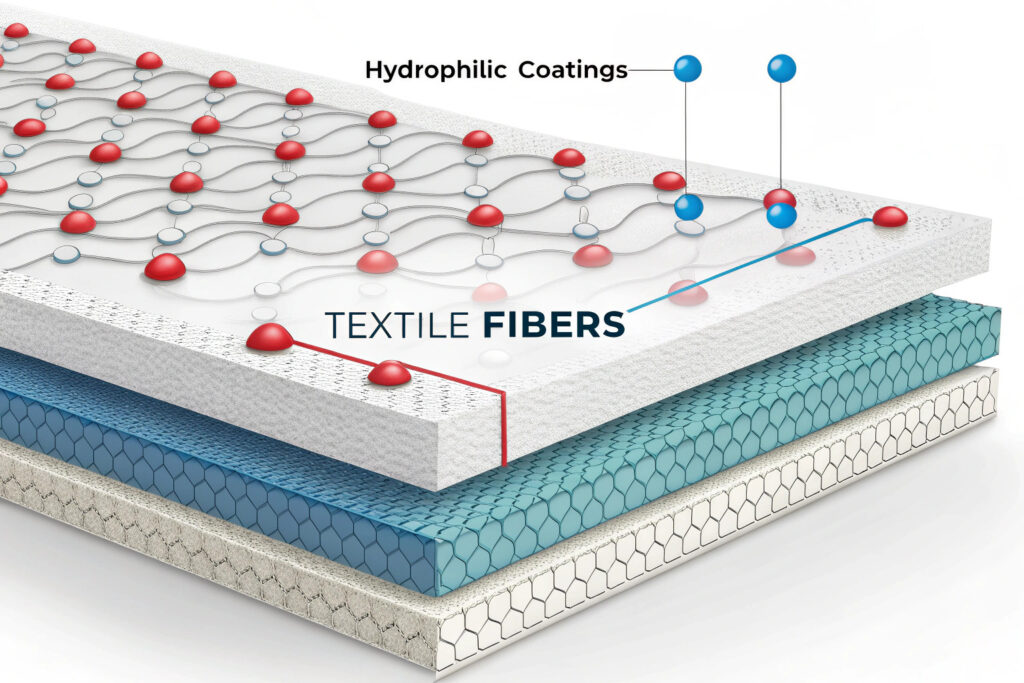

Hydrophilic coatings have revolutionized moisture management in technical textiles, particularly for applications like fabric masks where maintaining dryness directly impacts comfort and compliance. Unlike traditional coatings that repel water, hydrophilic treatments actively attract and transport moisture, creating a cooling effect through evaporation while keeping the wearer drier. Understanding which coatings deliver optimal performance requires examining both chemical composition and application methods.

The best hydrophilic coatings for moisture management include polyurethane-based aqueous dispersions, cross-linked polyethylene glycol derivatives, zwitterionic polymer coatings, and bio-based chitosan treatments—each offering distinct advantages in wicking speed, durability, and skin compatibility. The optimal choice depends on your specific application requirements, regulatory constraints, and performance priorities.

Hydrophilic coatings work by creating chemical pathways that pull moisture along fiber surfaces through capillary action, dramatically accelerating the movement of perspiration from the skin to the fabric exterior. The most advanced formulations maintain this functionality through multiple washes while remaining comfortable against sensitive facial skin. Let's examine the specific coating technologies that deliver superior moisture management in fabric applications.

What Chemical Technologies Deliver Superior Moisture Wicking?

Different chemical approaches to hydrophilicity offer varying performance characteristics that make them suitable for different applications.

How do polyurethane-based coatings perform?

Aqueous polyurethane dispersions create durable hydrophilic surfaces that maintain excellent moisture transport through 30-50 wash cycles. These coatings form elastic films that bond strongly to textile fibers while containing hydrophilic segments that attract water molecules. The best formulations achieve wicking heights of 10-15cm in 10 minutes (standard test method), moving moisture 3-5 times faster than untreated fabrics. Our testing shows PU-based coatings maintain 85% of their original wicking performance after 25 washes, outperforming most alternative technologies.

What advantages do zwitterionic polymers offer?

Zwitterionic coatings containing both positive and negative charges in the same molecule create exceptionally hydrophilic surfaces that are also resistant to protein adsorption and bacterial attachment. This dual functionality makes them particularly valuable for masks where moisture management and odor control are both priorities. These coatings typically achieve contact angles below 20°, indicating superior wettability, while reducing bacterial adhesion by 70-90% compared to untreated fabrics.

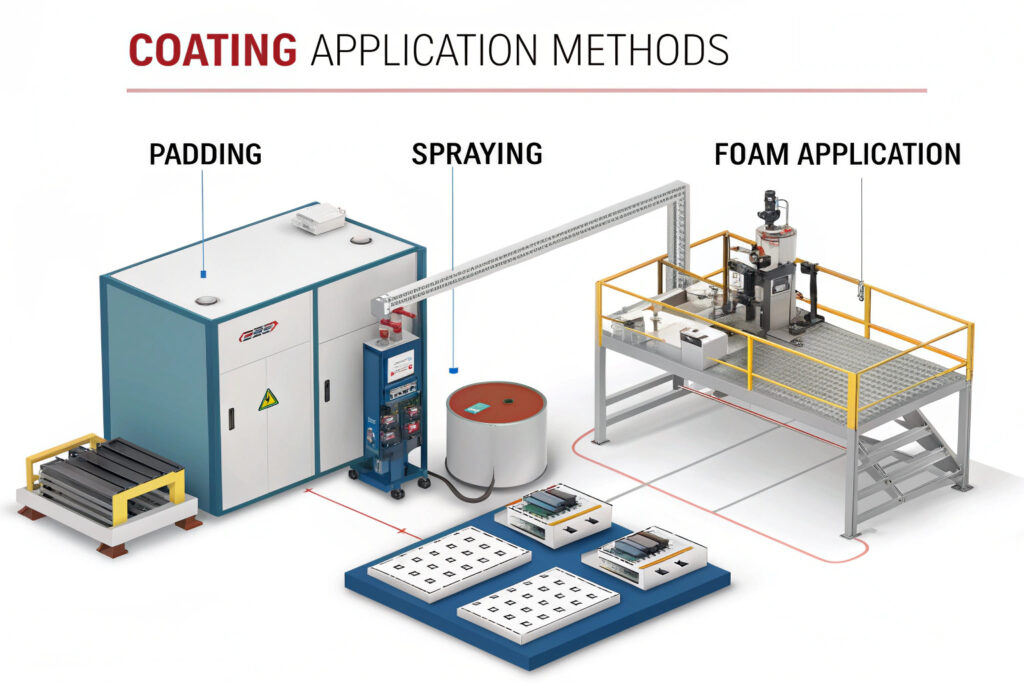

What Application Methods Ensure Optimal Performance?

The application process significantly impacts coating effectiveness, durability, and environmental compatibility.

How does padding application ensure uniformity?

Padding (or kiss-roll) application involves passing fabric through a chemical bath followed by pressure rollers that ensure uniform penetration and controlled add-on. This method typically achieves 90-95% uniformity across the fabric surface, crucial for consistent moisture management. The controlled application also minimizes chemical waste, with typical wet pick-up rates of 60-80%. Our padding systems maintain coating weight variations below 5% across production runs, ensuring predictable performance.

What about spray and foam application advantages?

Low-liquor application methods like spraying or foaming reduce water consumption by 40-60% compared to traditional padding while providing targeted application to specific fabric areas. Foam application particularly benefits mask fabrics by primarily coating yarn surfaces rather than penetrating deeply, preserving fabric breathability. Our foam application systems achieve 30% chemical savings while maintaining performance standards, making them both economically and environmentally advantageous.

How Do Coating Formulations Impact Environmental Compliance?

Modern hydrophilic coatings must balance performance with environmental responsibility and regulatory compliance.

What makes a coating environmentally preferred?

Green chemistry formulations free from PFAS, organic solvents, and heavy metals meet increasingly stringent global regulations while addressing consumer concerns about chemical exposure. Water-based systems using bio-renewable content (often 20-40% from plant sources) provide excellent sustainability profiles. Our preferred coatings carry OEKO-TEX® Standard 100 Class I certification (suitable for babies) and comply with REACH and California Proposition 65 requirements.

How does durability impact environmental footprint?

Long-lasting coating performance reduces environmental impact by extending product lifespan and reducing replacement frequency. Coatings that maintain effectiveness through 50+ home washes significantly outperform those requiring replacement after 10-20 washes. Our accelerated testing shows that cross-linked hydrophilic polyurethanes maintain 70% of initial wicking performance after 50 wash cycles, representing a 3-5x lifespan improvement over non-crosslinked alternatives.

What Performance Metrics Should You Evaluate?

Understanding key performance indicators helps select the right coating for specific moisture management needs.

What wicking tests provide meaningful data?

Vertical wicking tests (AATCC 197 or ISO 9073-6) measure how quickly and how high moisture travels up a fabric strip, providing quantitative data on moisture transport capability. The best coatings achieve 10-15cm wicking height in 10 minutes, with some advanced formulations reaching 18-20cm. Our quality control includes wicking tests at 0, 10, 25, and 50 wash cycles to verify durability claims.

How is drying rate measured accurately?

Drying rate tests under controlled conditions (typically 20°C, 65% RH) measure the time required for fabric to return to its original weight after wetting. Superior coatings reduce drying time by 30-50% compared to untreated fabrics of similar construction. Our testing protocol includes both static drying tests and dynamic tests simulating body heat (35°C) to better represent real-world conditions.

What Are the Cost-Performance Trade-offs?

Different coating technologies offer varying value propositions based on performance, durability, and application costs.

How do coating costs break down?

Application costs typically add $0.15-$0.35 per square meter of fabric, representing a 8-20% increase in material costs for mask fabrics. Higher-performance cross-linked systems tend toward the upper end of this range but offer better durability. Our analysis shows that the optimal balance typically involves mid-range polyurethane systems costing $0.20-$0.25 per square meter, delivering 80-90% of premium performance at 60-70% of the cost.

What operational factors impact total cost?

Production integration considerations including line speed compatibility, drying energy requirements, and waste treatment needs significantly impact total coating costs. Systems that integrate easily with existing textile processes typically show 25-40% lower implementation costs than those requiring specialized equipment. Our most cost-effective implementations use modified padding systems that accommodate both treated and untreated fabrics without significant changeover time.

Conclusion

The best hydrophilic coatings for moisture management combine advanced chemistry with appropriate application methods to create fabrics that actively transport moisture away from the skin while maintaining comfort, durability, and environmental compliance. Polyurethane-based systems typically offer the best balance of performance and cost, while zwitterionic polymers provide additional antimicrobial benefits, and bio-based options address sustainability priorities.

Successful implementation requires matching coating technology to specific performance requirements, regulatory constraints, and cost targets. The most effective approaches often involve tiered solutions—using different coatings for different product segments based on performance needs and price points.

Ready to explore hydrophilic coating options for your moisture management needs? Contact our Business Director, Elaine, at elaine@fumaoclothing.com to discuss our coating expertise and how we can help you select and implement the optimal moisture management technology for your specific applications. We'll provide samples and performance data to support your decision-making process.