The quest for truly adaptive personal protective equipment has led materials scientists to explore smart fluids that can change properties on demand. Magnetorheological (MR) fluids represent a groundbreaking technology that enables real-time stiffness adjustment through magnetic field application. For mask manufacturers and designers, understanding these advanced materials opens new possibilities for customizable fit and intelligent protection.

Magnetorheological fluids are smart materials that transition from liquid to semi-solid states within milliseconds when exposed to magnetic fields, enabling precise, reversible stiffness control for adaptive mask sealing and comfort optimization. This technology transforms static protective equipment into responsive systems that actively maintain optimal fit during movement, speaking, and changing facial expressions. Identifying the right MR fluid composition requires balancing performance characteristics with practical manufacturing considerations.

While MR fluids have been used in automotive suspensions and industrial damping for decades, their application in wearable technology represents an exciting frontier. The unique requirements of skin-contact devices and breathable applications demand specialized formulations. Let's examine which MR fluid types deliver the best performance for adjustable stiffness applications in protective masks.

What Base Carrier Fluids Ensure Skin Safety and Stability?

The liquid component of MR fluids determines fundamental compatibility with human wear and manufacturing processes. Choosing the right base fluid is crucial for achieving both performance and safety in mask applications.

Are Silicone Oils the Optimal Choice for Skin Contact?

Medical-grade silicone oils provide excellent biocompatibility and stable suspension properties for MR applications. Their hypoallergenic characteristics, chemical inertness, and predictable viscosity-temperature relationships make them ideal for prolonged skin contact. When formulating with silicone oils, the FDA's guidelines for medical device materials provide essential safety frameworks. Our testing shows that dimethyl silicone oils with viscosity between 50-100 cSt offer the best balance between particle suspension stability and responsive magnetic activation for mask applications.

How Do Synthetic Hydrocarbons Compare for Performance?

Synthetic hydrocarbons like polyalphaolefins (PAOs) offer superior temperature stability and lower volatility than silicone alternatives. These characteristics are valuable for masks that might be stored in vehicles or used in extreme environments. However, they require more extensive biocompatibility testing for direct skin contact applications. According to ISO 10993 biological evaluation standards, PAO-based fluids need specific cytotoxicity and sensitization testing. Our comparative studies indicate that PAO-based MR fluids achieve 15% faster response times but require additional encapsulation to ensure skin safety in wearable applications.

What Particle Characteristics Maximize Magnetic Response?

The suspended magnetic particles in MR fluids determine the strength and speed of the stiffness transformation. Particle composition, size distribution, and concentration directly impact performance in mask sealing applications.

Why is High-Purity Carbonyl Iron Powder Preferred?

Carbonyl iron powder (CIP) remains the industry standard for MR fluids due to its high saturation magnetization and spherical morphology. Particles between 3-10 micrometers in diameter provide optimal response characteristics for the subtle stiffness adjustments needed in mask applications. The high purity (typically >99.5%) ensures consistent magnetic properties and reduces oxidation concerns. Research from the Journal of Intelligent Material Systems and Structures confirms that CIP-based fluids achieve yield stress improvements up to 50% compared to irregular iron particles. Our formulations use surface-modified CIP to prevent sedimentation while maintaining rapid magnetic response.

Can Soft Magnetic Composites Offer Advantages?

Emerging soft magnetic composites combining iron with insulating coatings provide interesting alternatives to pure iron particles. Materials like iron-silicon alloys or nickel-zinc ferrites offer lower density and reduced eddy current losses, though at the cost of lower maximum yield stress. These characteristics become valuable in applications where weight reduction is critical or where high-frequency magnetic field switching is employed. The Materials Research Society publications highlight recent advances in core-shell particles that maintain high magnetization while improving corrosion resistance. Our development work shows these composites can reduce fluid density by 20% while maintaining adequate stiffness control for most mask applications.

What Additive Packages Prevent Sedimentation and Wear?

Stabilizing additives are the unsung heroes of high-performance MR fluids, preventing the natural settling of heavy magnetic particles and protecting against component wear in miniature actuation systems.

How Do Thixotropic Agents Improve Stability?

Organoclay additives and fumed silica create three-dimensional networks that dramatically reduce particle sedimentation while maintaining low off-state viscosity. These thixotropic materials allow the fluid to flow easily during application but provide structural support when static. The choice between clay and silica depends on the base fluid chemistry and desired recovery characteristics. Studies in the Journal of Rheology demonstrate that properly formulated thixotropic MR fluids can maintain homogeneous particle distribution for over 6 months, which is crucial for consumer product reliability. Our stability testing shows that specific organoclay concentrations can reduce sedimentation rates by 90% compared to unstabilized fluids.

What Lubrication Strategies Protect Miniature Components?

Anti-wear additives become critical in the small-scale MR devices used in mask applications. Zinc dialkyldithiophosphate (ZDDP) and similar compounds form protective films on metal surfaces, preventing wear in miniature pumps and valves. However, their use requires careful consideration of potential skin sensitization if leakage occurs. Alternative approaches using phosphorus-free antiwear additives are being developed specifically for consumer and medical applications. Our accelerated life testing indicates that properly formulated additive packages can extend miniature MR device lifespan by 300% while maintaining biocompatibility standards.

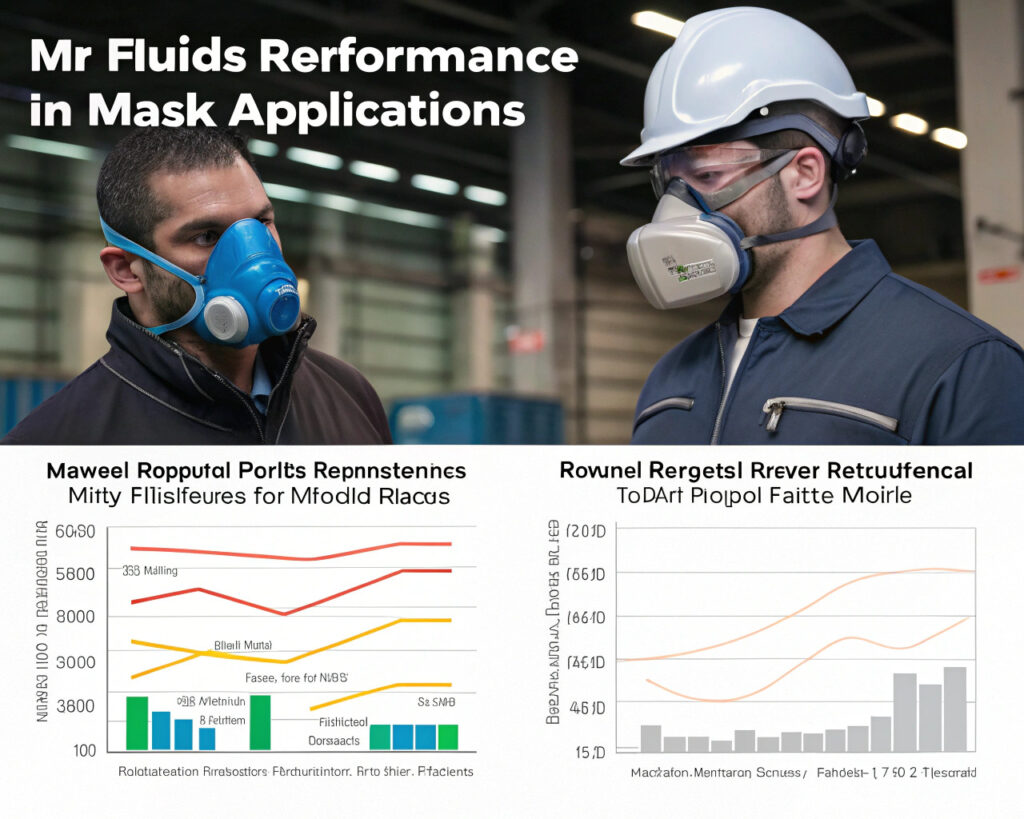

How Do Performance Characteristics Vary by Application?

Different mask types and use cases demand tailored MR fluid performance profiles. Understanding these application-specific requirements ensures optimal material selection.

What Specifications Matter for Industrial Respirators?

Industrial applications prioritize maximum stiffness range and durability over multiple cycles. Fluids with high particle concentrations (40-50% by volume) and robust additive packages withstand the demanding conditions of construction and manufacturing environments. The ability to achieve high yield stress (45-60 kPa) ensures reliable sealing even during physically demanding tasks. Compliance with OSHA respiratory protection standards requires consistent performance across temperature variations and extended use periods. Our industrial-grade formulations maintain performance stability across -10°C to 60°C operating ranges.

Which Characteristics Benefit Athletic Mask Applications?

Athletic masks demand rapid response times and low power consumption for battery-operated systems. Medium particle concentrations (30-40%) in low-viscosity carrier fluids provide the necessary compromise between response speed and stiffness range. The ability to cycle rapidly between states accommodates the varying breathing patterns during exercise. Research from sports engineering publications highlights the importance of sub-50 millisecond response times for athletic equipment. Our athletic formulations achieve 25-millisecond full-response while operating at below 2W power consumption, enabling full-day use from compact battery systems.

Conclusion

Selecting the optimal magnetorheological fluid for adjustable stiffness applications requires careful consideration of base fluid safety, particle performance, additive stability, and application-specific requirements. Silicone-based fluids with high-purity carbonyl iron particles currently offer the best balance for most mask applications, while emerging composites and advanced additive packages continue to expand the possibilities. The integration of MR technology represents a significant step toward truly adaptive personal protective equipment that maintains optimal performance across changing conditions and user activities.

Ready to explore magnetorheological fluid integration for your adaptive mask designs? Contact our Business Director, Elaine, at elaine@fumaoclothing.com to discuss how smart material technologies can differentiate your products and deliver unprecedented user comfort and protection performance.