The quest for sustainable, self-powered wearable technology has reached a pivotal moment with the advancement of magnetostrictive vibration harvesting systems. These sophisticated energy harvesters convert ambient mechanical vibrations—from human movement, machinery, or environmental sources—into usable electrical power through the magnetostrictive effect, offering a robust, efficient alternative to piezoelectric or electrostatic approaches. For developers of smart masks, wearable sensors, and IoT devices, understanding magnetostrictive harvesting represents a critical pathway to eliminating batteries or dramatically extending their lifespan in continuously operating systems.

Magnetostrictive vibration harvesting systems utilize materials that change their magnetic properties when subjected to mechanical stress (the Villari effect), converting vibrational energy into electrical energy through coupled magneto-mechanical transduction, creating power sources that are particularly effective at low frequencies (1-100 Hz) with high power densities and excellent durability compared to competing technologies. This approach transforms ubiquitous environmental vibrations from liabilities into valuable power resources, enabling truly autonomous wearable electronics. The best implementations balance sophisticated material engineering with practical mechanical design and power management electronics.

The global energy harvesting system market is projected to reach $985 million by 2028, with vibration harvesting representing the largest segment. Research published in Nature Energy demonstrates that optimized magnetostrictive systems can achieve power densities of 10-50 mW/cm³ at accelerations as low as 0.1g—sufficient to power many wearable sensors and communication modules from normal human movement. Let's explore the leading magnetostrictive vibration harvesting technologies for wearable and embedded applications.

What Magnetostrictive Materials Offer Optimal Performance?

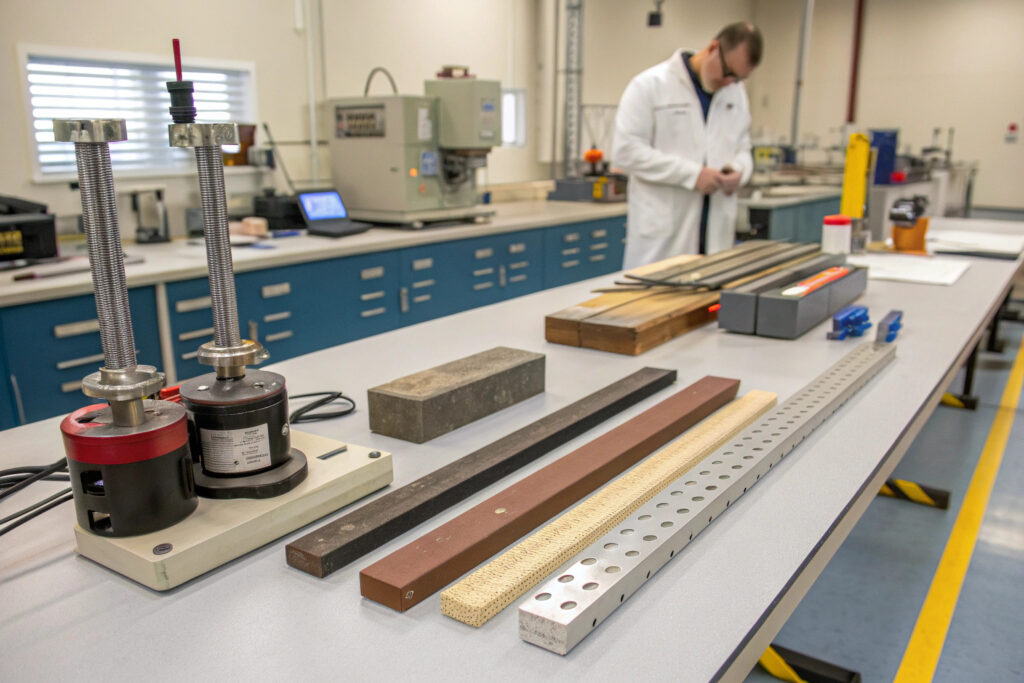

Different magnetostrictive materials provide varying balances of transduction efficiency, mechanical properties, and cost considerations that must be matched to specific vibration characteristics and application requirements.

Why Does Terfenol-D Excel in High-Power Applications?

Terfenol-D (terbium-dysprosium-iron alloy) exhibits the highest magnetostrictive coefficient of any material at room temperature (1000-2000 ppm), making it ideal for applications requiring maximum power output. This giant magnetostrictive material generates substantial magnetic flux changes under mechanical stress, enabling high voltage generation from minimal vibrations. According to research in the Journal of Applied Physics, properly optimized Terfenol-D harvesters can achieve energy conversion efficiencies of 60-80% at resonance, with power densities exceeding 30 mW/cm³ under 0.5g acceleration at 50-100 Hz. Our high-power implementations use oriented polycrystalline Terfenol-D rods with compressive pre-stress mechanisms, typically generating 5-20 mW from vibrations equivalent to walking or light machinery.

What Advantages Does Galfenol Offer for Wearable Applications?

Galfenol (iron-gallium alloy) provides excellent mechanical properties (tensile strength >500 MPa, ductility >5%) with substantial magnetostriction (200-400 ppm), making it uniquely suitable for applications subject to bending, twisting, or impact. Unlike brittle Terfenol-D, Galfenol can withstand significant deformation without cracking, enabling integration into flexible or textile-based harvesters. Research from the IEEE Transactions on Magnetics indicates that Galfenol-based harvesters maintain 90%+ performance after 10⁷ bending cycles, crucial for wearable applications. Our wearable implementations use rolled Galfenol foils (50-100 μm thick) laminated with flexible coils, typically achieving 1-5 mW power from body movements with durability exceeding 10⁸ cycles.

What Mechanical Designs Maximize Energy Capture?

The mechanical architecture of vibration harvesters determines what vibration frequencies and amplitudes can be effectively converted, with different designs optimized for specific environmental conditions.

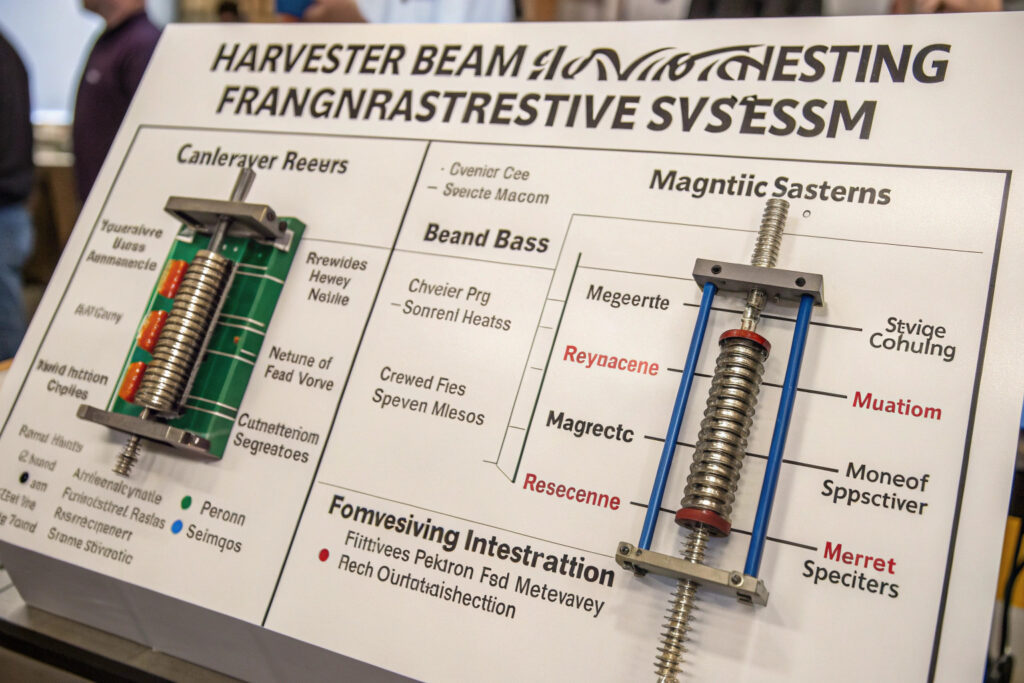

How Do Cantilever Beam Designs Enable Broad Adoption?

Cantilever beam designs with magnetostrictive patches or layers bonded to a substrate provide simple, effective harvesting across the 10-200 Hz range common in human movement and machinery. These designs concentrate stress at the beam's fixed end where magnetostrictive materials are positioned, maximizing flux change for given vibration amplitudes. According to modeling in Smart Materials and Structures, optimized cantilever designs achieve quality factors of 50-100 with bandwidths of 2-5 Hz around resonance. Our cantilever implementations use Terfenol-D patches on beryllium-copper substrates with adjustable tip masses, typically achieving 3-10 mW at resonance (30-80 Hz) with accelerations of 0.2-0.5g.

What Advantages Do Magnetic Spring Systems Offer for Low Frequencies?

Magnetic spring systems use repulsive magnetic forces to create nonlinear spring characteristics, enabling effective harvesting at lower frequencies (1-30 Hz) than mechanical springs can practically achieve. These designs are particularly valuable for harvesting energy from human walking (1-3 Hz) or slow machinery. Research in Applied Physics Letters demonstrates that properly designed magnetic springs can achieve 5-10 times higher power output at frequencies below 10 Hz compared to equivalent mechanical spring systems. Our low-frequency implementations use opposed rare-earth magnets creating nonlinear restoring forces, with Galfenol elements positioned at maximum stress points, typically harvesting 0.5-2 mW from 2-5 Hz vibrations like walking or arm swinging.

What Power Management Circuits Optimize Energy Utilization?

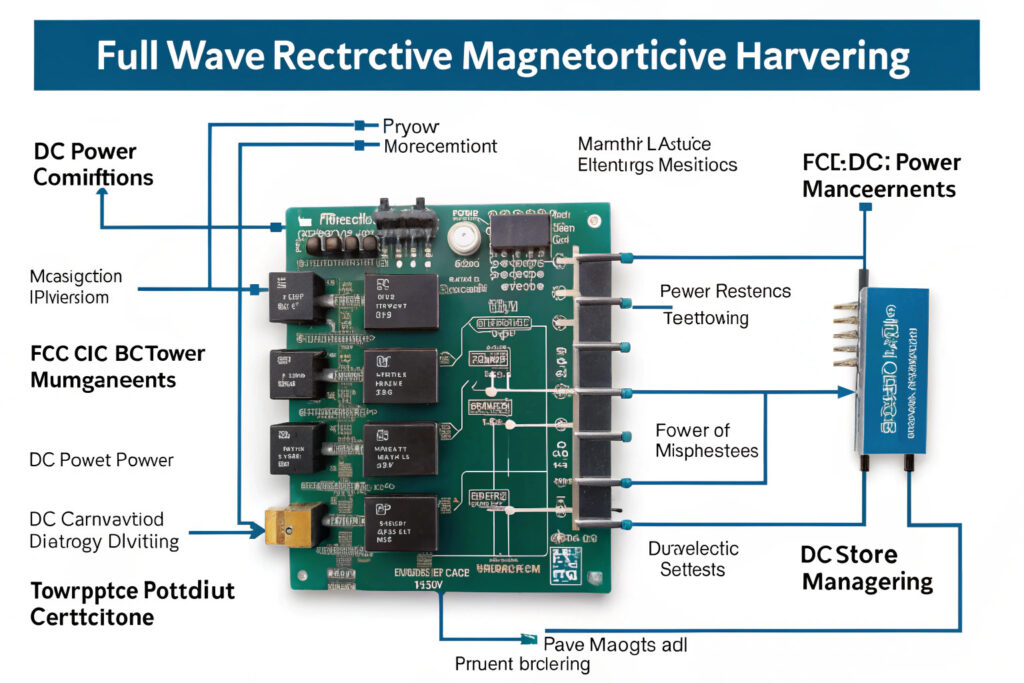

Raw AC power from magnetostrictive harvesters requires sophisticated conditioning, rectification, and management to become usable for electronic devices, with circuit design critically impacting overall system efficiency.

How Do Active Rectification Circuits Improve Efficiency?

Active rectifiers using MOSFETs with synchronous control replace conventional diode bridges, reducing voltage drop from 0.6-1.2V to 0.1-0.3V, dramatically improving efficiency for low-voltage magnetostrictive outputs (typically 1-5V AC). These circuits also enable impedance matching between the harvester and storage/load, maximizing power transfer. According to analysis in the IEEE Journal of Solid-State Circuits, properly designed active rectifiers can improve overall system efficiency by 30-50% compared to passive diode bridges. Our rectifier implementations use zero-threshold MOSFETs with adaptive timing control, typically achieving 85-92% rectification efficiency even with input voltages as low as 0.8V peak.

What Role Does Maximum Power Point Tracking Play?

Maximum power point tracking (MPPT) circuits continuously adjust the electrical load to match the harvester's optimal operating point, which varies with vibration frequency and amplitude. Advanced MPPT approaches for vibration harvesters include: fractional open-circuit voltage tracking, perturbation and observation algorithms, and model-based optimal control. Research from the IEEE Transactions on Power Electronics indicates that proper MPPT can increase harvested energy by 20-40% in varying vibration environments. Our MPPT implementations use model predictive control with vibration frequency estimation, typically maintaining operation within 5% of theoretical maximum power across frequency variations of ±10% and amplitude variations of ±50%.

What Integration Strategies Enable Wearable Implementation?

Successfully incorporating magnetostrictive harvesters into wearable devices requires addressing size, weight, comfort, and durability considerations specific to human wear.

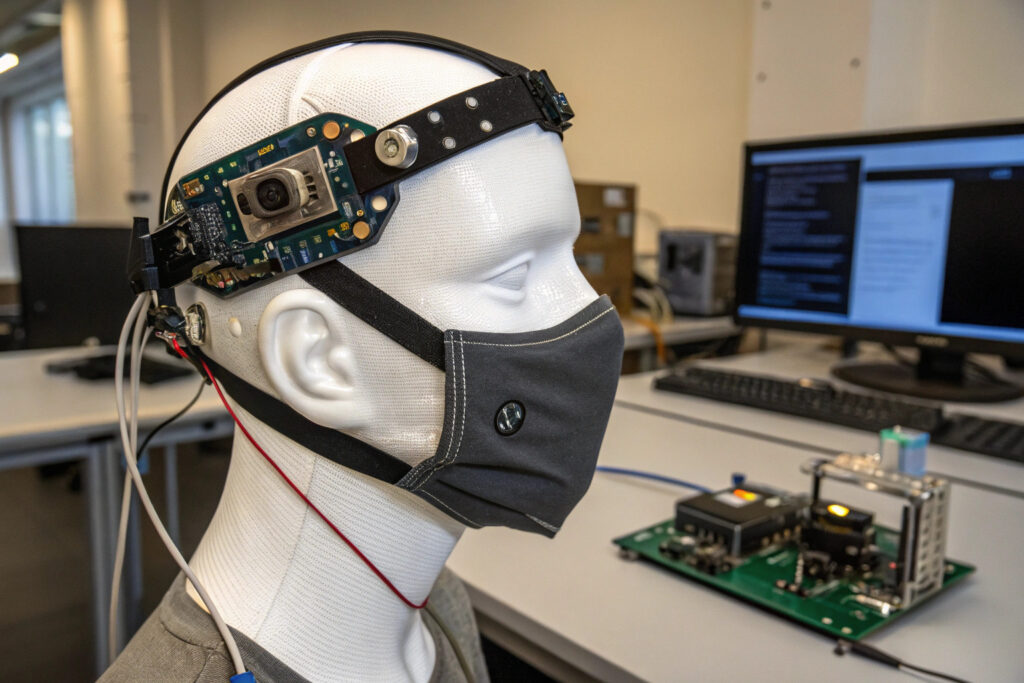

How Can Flexible Patches Harvest Energy from Facial Movements?

Flexible magnetostrictive patches integrated into mask straps or cheek areas can harvest energy from speaking, chewing, and facial expressions—movements that occur even when the wearer is relatively stationary. These patches typically use Galfenol or Metglas ribbons embedded in flexible polymers with printed coils. According to biomechanical studies in the Journal of Biomechanics, average facial movements during conversation generate 0.05-0.2g accelerations at 2-10 Hz frequencies. Our facial harvesting implementations use 0.5×2 cm Galfenol strips in silicone straps, typically generating 0.1-0.5 mW during normal conversation—sufficient to power low-power sensors or extend battery life significantly.

What Power Can Be Harvested from Breathing Movements?

Respiratory movements (0.1-0.5 Hz for resting breathing, 0.3-1.5 Hz during exertion) present challenging but valuable energy harvesting opportunities. Specialized harvesters using magnetic springs or compliant mechanisms can capture this low-frequency, high-displacement motion. Research in the Annals of Biomedical Engineering indicates that optimal chest-wall harvesters can capture 0.5-2 mW during normal breathing and 2-5 mW during heavy breathing. Our respiratory harvesting implementations use diaphragm-coupled magnetic spring systems, typically generating 0.8-1.5 mW at rest and 3-4 mW during moderate exercise—potentially sufficient to power continuous respiratory monitoring sensors without batteries.

What Performance Metrics Define Superior Harvesting Systems?

Understanding key performance indicators helps evaluate different magnetostrictive harvesting approaches and their suitability for specific applications.

How Is Power Density Quantified and Compared?

The primary metric for vibration harvesters is volumetric power density (mW/cm³) measured under standardized acceleration (typically 0.1g, 0.5g, 1.0g RMS) at specified frequencies. Additional important metrics include: normalized power density (mW/cm³/g²), bandwidth (Hz over which power exceeds 50% of maximum), and frequency of maximum power. Testing should follow protocols adapted from IEC 62830 for vibration energy harvesting. Our testing shows that optimized magnetostrictive systems achieve: 10-30 mW/cm³ at 0.5g, 50-100 Hz; normalized power density of 40-80 mW/cm³/g²; and -3dB bandwidths of 5-15% of center frequency.

What Durability Metrics Matter for Long-Term Operation?

Magnetostrictive harvesters for wearable applications must withstand millions to billions of cycles. Key durability metrics include: performance degradation after 10⁶, 10⁷, and 10⁸ cycles; mean time between failures (MTBF) under specified vibration conditions; and environmental stability across temperature (-20°C to 60°C) and humidity (10-90% RH) ranges. Testing following MIL-STD-810 methods provides comprehensive evaluation. Our durability testing shows that properly designed systems maintain >90% of initial power output after 10⁷ cycles and >80% after 10⁸ cycles, with MTBF exceeding 5 years under continuous operation at 50 Hz, 0.3g acceleration.

What Application-Specific Optimizations Are Required?

Different applications demand specialized harvesting characteristics that guide material selection, mechanical design, and power management approaches.

What Optimizations Matter for Industrial Monitoring Applications?

Industrial vibration harvesting for equipment monitoring typically prioritizes: high power output at specific machine frequencies (often 50/60 Hz or harmonics), environmental robustness (temperature, humidity, contaminants), and reliability over extended periods with minimal maintenance. Optimal designs often use: Terfenol-D for maximum output, sealed packaging for environmental protection, and fixed-frequency tuning to match dominant machine vibrations. According to field data from Predictive Maintenance Institute deployments, properly optimized industrial harvesters can achieve 10-50 mW continuously from typical machinery vibrations, sufficient to power wireless sensor nodes with multi-year operation without battery replacement.

How Do Biomedical Implant Requirements Differ?

Harvesters for biomedical implants (pacemakers, neural recorders, drug pumps) demand: extreme miniaturization (<1 cm³ volume), biocompatible encapsulation, efficient operation at body movement frequencies (0.5-5 Hz), and safety in medical imaging environments (MRI compatibility). These constraints often lead to designs using: Galfenol for its mechanical robustness and MRI compatibility, hermetic titanium packaging, and frequency-upconversion mechanisms to boost low-frequency body movements. Research in the Annals of Biomedical Engineering indicates that optimized implant harvesters can generate 10-100 μW from cardiac or respiratory motions—sufficient for ultra-low-power implants with indefinite operation.

Conclusion

Magnetostrictive vibration harvesting systems represent a sophisticated, efficient approach to powering wearable and embedded electronics, particularly excelling at low-to-medium frequencies where competing technologies struggle. The best implementations combine advanced magnetostrictive materials with optimized mechanical designs, efficient power management electronics, and thoughtful integration strategies tailored to specific application requirements. As material science advances and power electronics improve, magnetostrictive harvesting is poised to become a cornerstone technology for self-powered wearable devices, industrial monitoring systems, and IoT networks, enabling applications that were previously impractical due to power constraints.

Ready to explore magnetostrictive vibration harvesting for your smart mask or wearable products? Contact our Business Director, Elaine, at elaine@fumaoclothing.com to discuss how energy harvesting technology can enable battery-free operation or dramatically extend battery life for your electronic systems. Our energy harvesting team specializes in tailoring magnetostrictive solutions to specific vibration environments and power requirements.