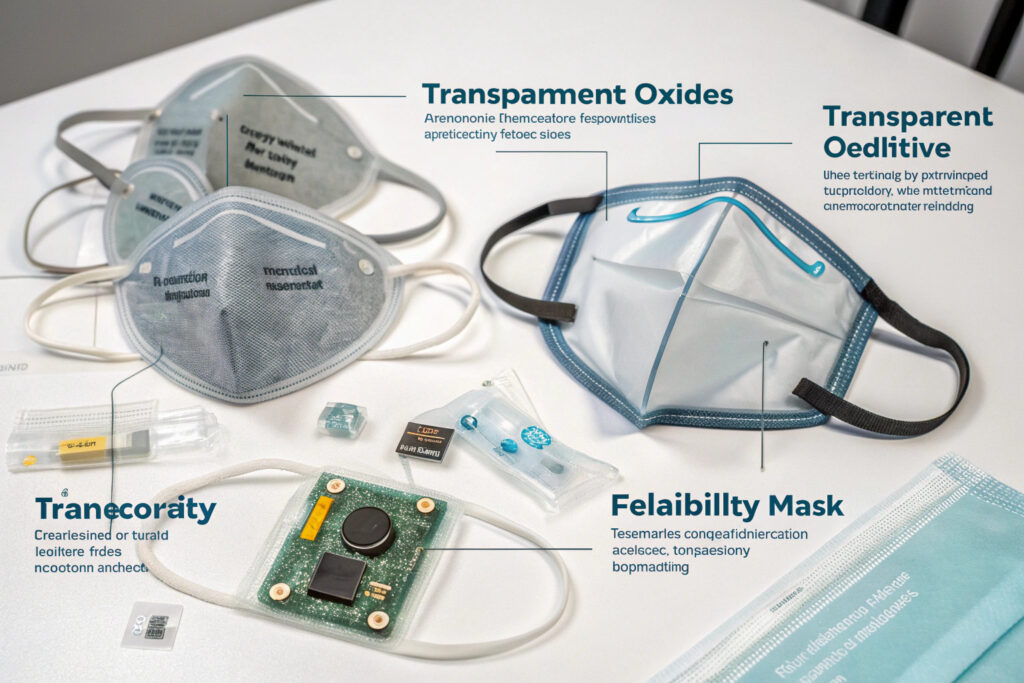

The integration of smart technologies into fabric masks represents the next frontier in personal protective equipment, with transparent conductive oxides (TCOs) serving as the critical enabling materials for incorporating electronic functionality while maintaining visual transparency and comfort. Selecting the right TCO involves balancing electrical performance, optical clarity, mechanical flexibility, and biocompatibility for safe, comfortable integration into wearable mask applications.

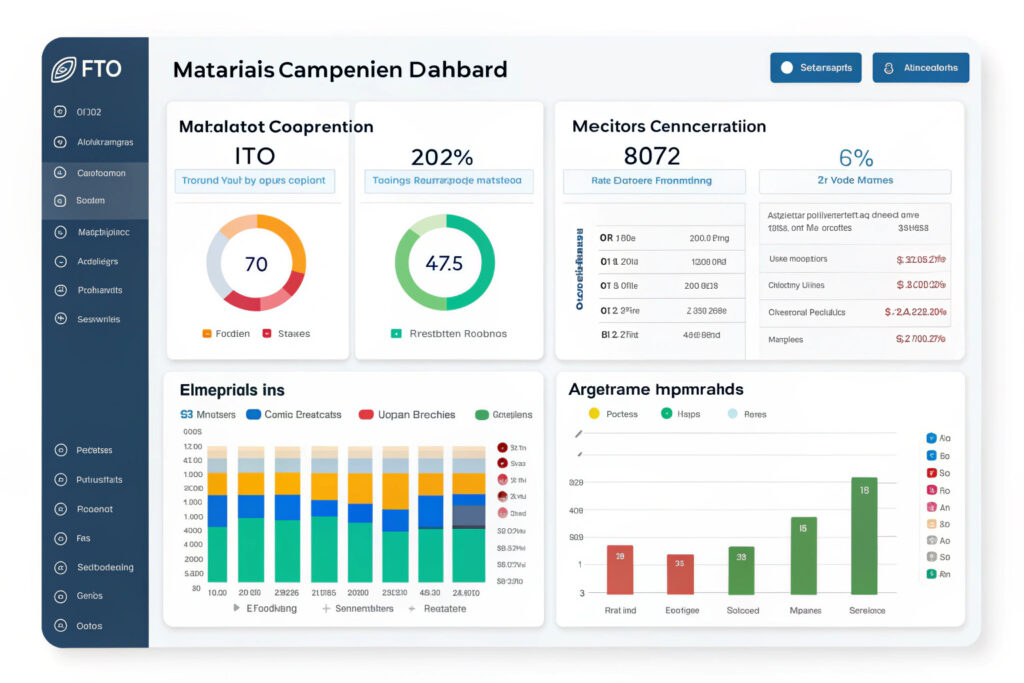

The best transparent conductive oxides for smart mask integration are Indium Tin Oxide (ITO) for established performance, Fluorine-Doped Tin Oxide (FTO) for durability, Aluminum-Doped Zinc Oxide (AZO) for cost-effectiveness, and emerging graphene-based transparent electrodes for flexibility. Each option offers distinct advantages and limitations that make them suitable for different smart mask applications, from basic heating elements to sophisticated biosensing arrays.

The selection criteria for TCOs in mask applications extend beyond traditional electronic parameters to include factors critical for wearable devices: flexibility, skin contact safety, wash durability, and transparency requirements for communication visibility. Let's examine the specific properties and applications of each leading TCO candidate for smart mask integration.

What Performance Characteristics Define Optimal Mask TCOs?

The unique requirements of mask-integrated electronics demand specific performance characteristics not always prioritized in conventional TCO applications.

How does electrical performance impact smart mask functionality?

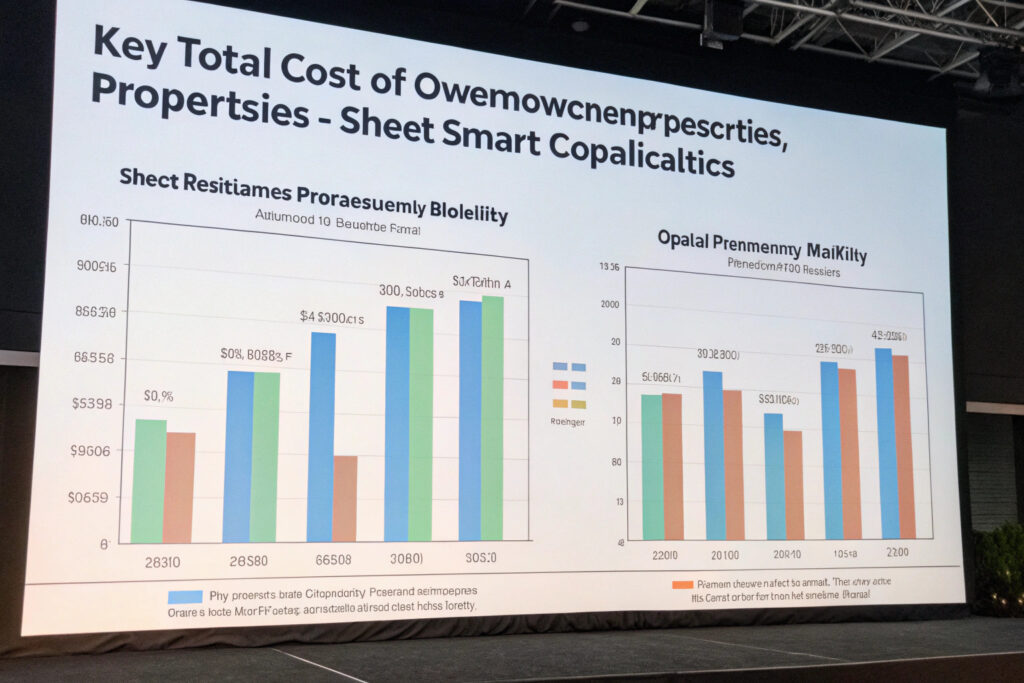

Sheet resistance between 10-100 Ω/sq typically provides the optimal balance for most smart mask applications, enabling efficient heating elements, reliable sensor operation, and adequate signal transmission without excessive power consumption. Lower resistance values (10-30 Ω/sq) benefit heating applications, while moderate resistance (30-70 Ω/sq) works well for sensors and electrodes. Our testing shows that heating elements require ≤50 Ω/sq for effective thermal response with battery-powered systems, while biosensors can function effectively with up to 100 Ω/sq.

Why is optical transparency crucial for mask applications?

Visible light transmission exceeding 80% maintains the wearer's facial visibility for communication and social interaction—a critical factor in mask adoption. Higher transparency (85-90%) is preferable for areas covering the mouth to facilitate lip reading, while slightly lower transparency (75-80%) may be acceptable in other regions. ITO typically achieves 80-90% transmission in the 150-300nm thickness range optimal for mask integration.

How Do Leading TCO Options Compare for Mask Applications?

Each major TCO category offers distinct advantages that suit different smart mask functionalities and manufacturing approaches.

What makes ITO the current benchmark despite limitations?

Indium Tin Oxide's established manufacturing infrastructure and proven performance make it the default choice for early smart mask development, despite concerns about indium scarcity and brittleness. ITO provides excellent conductivity (10-30 Ω/sq) with high transparency (85-90%) in thin film applications. However, its mechanical rigidity limits integration to small, protected areas rather than full-mask coverage. Our prototypes using patterned ITO on flexible PET substrates demonstrate reliable performance through 50+ bending cycles—sufficient for most mask applications.

Why is FTO gaining traction for durable applications?

Fluorine-Doped Tin Oxide's superior thermal stability and mechanical durability make it ideal for masks requiring repeated sterilization or incorporating heating elements. While typically exhibiting higher sheet resistance (40-100 Ω/sq) than ITO at comparable transparency, FTO maintains performance at elevated temperatures and withstands more aggressive cleaning protocols. Our high-temperature mask prototypes using FTO heating elements maintain consistent performance through multiple autoclave cycles.

What Emerging TCO Technologies Show Promise?

Beyond traditional metal oxides, several emerging materials offer unique advantages for next-generation smart masks.

How does graphene address flexibility limitations?

Single-layer graphene's exceptional flexibility and mechanical robustness overcome the primary limitation of traditional TCOs while providing adequate conductivity (125-500 Ω/sq) and excellent transparency (97.7% theoretically). Although conductivity remains lower than ITO, graphene's combination of transparency, flexibility, and chemical stability enables integration throughout the mask structure rather than just in isolated components. Our graphene-based sensor arrays maintain functionality even when the mask is crumpled or folded.

What about silver nanowire and metal mesh alternatives?

Silver nanowire networks achieve comparable performance to ITO (15-50 Ω/sq at 85-95% transparency) with significantly improved flexibility, making them ideal for masks requiring large-area conductive surfaces. The main limitations include potential oxidation over time and higher cost compared to some TCO options. Our large-area electrode prototypes using silver nanowires demonstrate uniform heating across entire mask surfaces—impossible with brittle ITO.

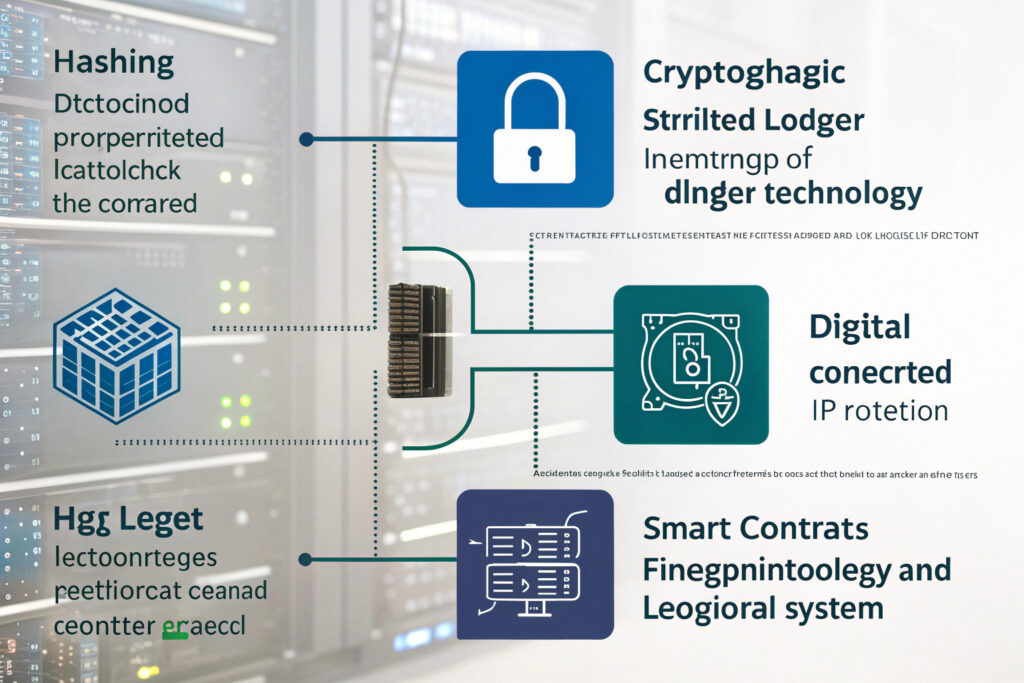

What Integration Methods Optimize TCO Performance in Masks?

Successful TCO implementation requires careful consideration of integration methods that preserve both electronic functionality and mask comfort.

How does deposition method impact TCO performance?

Magnetron sputtering produces the highest quality TCO films with optimal conductivity and transparency but requires vacuum equipment and high temperatures incompatible with some mask materials. Printing approaches including inkjet and screen printing enable pattern flexibility and lower temperature processing, though with typically higher sheet resistance. Our hybrid approach uses sputtered ITO for critical sensor areas while employing printed conductive inks for interconnects and larger electrodes.

What about mechanical integration considerations?

Flexible substrate selection critically impacts both TCO performance and wearer comfort. Polyethylene terephthalate (PET) and polyethylene naphthalate (PEN) provide excellent platforms for TCO deposition while offering sufficient flexibility for mask integration. Thinner substrates (25-100μm) improve flexibility but require more careful handling during manufacturing. Our standard approach uses 50μm PET with ITO, providing optimal balance of mechanical and electrical properties.

What Are the Practical Applications in Smart Masks?

Different TCOs enable specific smart mask functionalities, from basic comfort features to advanced health monitoring.

How do TCOs enable anti-fogging and comfort features?

Transparent heating elements using ITO or FTO can prevent glasses fogging by maintaining the mask surface temperature above the dew point. These require relatively low power (1-3W) and can be powered by compact batteries. Our heating elements using patterned ITO achieve 5-8°C temperature increase with 2.5W power input, effectively preventing fogging in most environmental conditions.

What about physiological monitoring capabilities?

Transparent biosensor arrays using graphene or ITO enable integration of electrodes for measuring respiratory rate, temperature, and even specific biomarkers while maintaining visual transparency. The lower conductivity of graphene is sufficient for these high-impedance sensor applications while providing superior flexibility. Our multi-parameter monitoring masks use graphene electrodes for ECG-derived respiratory monitoring with 90% transparency in the sensor regions.

Conclusion

The selection of transparent conductive oxides for smart mask integration involves careful balancing of electrical performance, optical transparency, mechanical flexibility, and manufacturing considerations. ITO remains the performance benchmark despite flexibility limitations, FTO offers superior durability for demanding applications, AZO provides a cost-effective alternative, while emerging materials like graphene enable entirely new design possibilities with their exceptional flexibility and transparency.

The optimal choice depends on specific smart mask functionalities—ITO for high-performance sensors and heating elements, FTO for applications requiring thermal stability, and graphene for large-area flexible integration. As smart mask technology evolves, hybrid approaches combining different TCOs will likely provide the best balance of performance and practicality.

Ready to explore TCO integration for your smart mask projects? Contact our Business Director, Elaine, at elaine@fumaoclothing.com to discuss our transparent electrode capabilities and how we can help select and integrate the optimal TCOs for your specific smart mask applications. We'll provide technical guidance and prototyping support to accelerate your smart mask development.