The quest for self-powered wearable electronics has made triboelectric nanogenerators (TENGs) one of the most promising energy harvesting technologies of the decade. By converting ubiquitous mechanical energy from motion, vibration, and even airflow into electrical power, TENGs offer a path to battery-free or perpetually charging smart devices. For manufacturers of advanced wearable technology like smart masks, understanding which TENG configurations and materials deliver optimal performance is crucial for designing truly autonomous products.

The best triboelectric nanogenerator power sources are those that efficiently convert specific, abundant mechanical energy sources in the user's environment into usable electrical power, utilizing material pairings with high triboelectric charge density, durable architectures, and efficient power management circuits to provide stable power for low-energy electronics. Their performance is not measured by a single metric but by their ability to deliver sufficient, reliable power for a target application under real-world conditions, considering factors like frequency of motion, magnitude of force, and user comfort.

The global TENG market is projected to grow at a CAGR of 28.3% from 2023 to 2033, driven by applications in IoT sensors, wearable health monitors, and personal electronics. Research in Nature Communications confirms that advanced TENGs can achieve peak power densities exceeding 500 W/m² and average outputs sufficient to power commercial sensors and microcontrollers. Let's dissect the key components that define the best TENG power sources for wearable applications.

What Material Pairings Maximize Charge Generation?

The heart of a TENG's performance lies in the triboelectric series—the ordering of materials based on their tendency to gain or lose electrons when contacted. Selecting the right material pair is the first and most critical design decision.

Which High-Performance Material Combinations Are Most Effective?

Pairs with the greatest separation on the triboelectric series yield the highest surface charge density. For wearables, the following combinations are prominent:

-

PTFE (Polytetrafluoroethylene) vs. Nylon: This classic pair offers one of the largest differences in electron affinity. PTFE is highly negative, while Nylon is strongly positive. Nanostructured PTFE (etched or imprinted) paired with woven Nylon can generate high voltage outputs, making it excellent for low-frequency, high-force applications.

-

FEP (Fluorinated Ethylene Propylene) vs. Copper/Aluminum: FEP is another strong electron-acceptor. When paired with conductive metals like copper as both a contact material and electrode, it enables simple and efficient contact-separation mode TENGs. Research in Advanced Energy Materials shows FEP-metal pairs can achieve charge densities over 250 µC/m².

-

PDMS (Polydimethylsiloxane) vs. PET (Polyethylene Terephthalate): PDMS is a versatile, flexible, and biocompatible negative material. Its surface can be easily micro- or nano-patterned (into pyramids, lines, or pores) to dramatically increase effective contact area. Paired with a positive material like PET, it is ideal for flexible, skin-conformable TENGs.

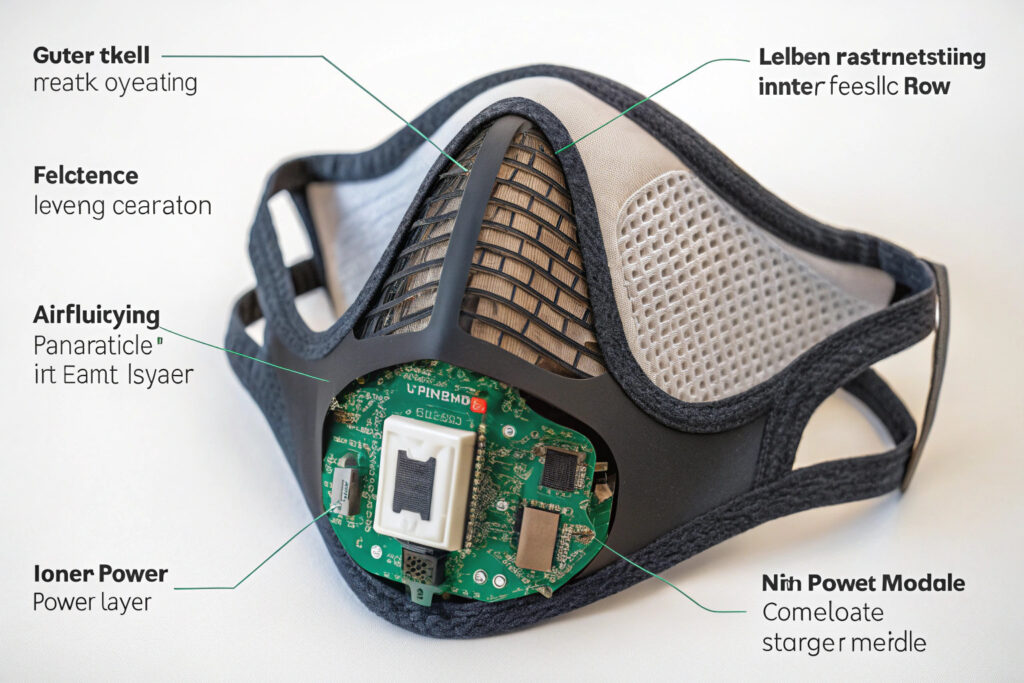

For mask applications, flexibility, breathability, and skin safety are paramount. Therefore, material pairs like nanostructured PDMS on a conductive fabric (as the negative side) against a nylon-based conductive fabric (as the positive side) are often optimal. They combine high triboelectric output with wearability.

How Does Surface Nanostructuring Amplify Output?

A smooth surface limits the contact area. Engineering micro- or nano-scale patterns (pillars, pyramids, wrinkles) onto the material surfaces can increase the effective contact area by 10-50 times. This dramatically boosts charge generation. For instance, creating pyramid arrays on PDMS via lithography or imprinting porous structures into PTFE via etching are standard techniques. According to studies in Nano Energy, proper nanostructuring can improve the power output of a TENG by an order of magnitude.

What Operational Modes Best Suit Wearable Energy Harvesting?

TENGs operate in four fundamental modes: vertical contact-separation, lateral sliding, single-electrode, and freestanding triboelectric-layer. The choice of mode dictates the design, integration method, and type of mechanical input harvested.

Why is Contact-Separation Mode Ideal for Breathing Harvesting?

The vertical contact-separation mode is perfectly suited for harvesting energy from the rhythmic expansion and contraction of a mask during breathing. In this mode, two triboelectric layers with back electrodes are brought into contact and then separated by a small gap (e.g., 1-5 mm). Each breath cycle drives this motion, generating an alternating current. Its advantages include:

- Simple Integration: Can be built into the mask's structure as a multi-layer composite.

- Effective at Low Frequency: Breathing is low-frequency (0.2-0.5 Hz), and this mode performs well under such conditions.

- Predictable Output: Generates a clear AC signal per breath.

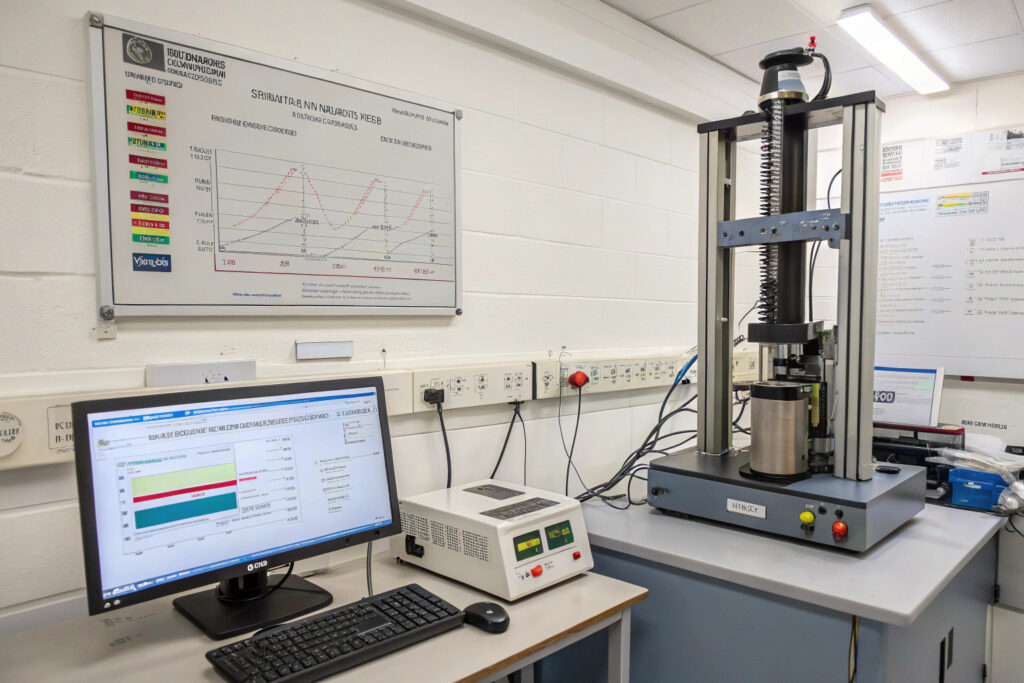

Our prototypes integrate a breath-responsive TENG in the cheek area using a flexible PDMS-PET pair in contact-separation mode, generating 10-50 µJ per breath cycle.

When is the Single-Electrode Mode Advantageous?

The single-electrode mode is invaluable when one object (like a moving part of the body) is not easily connected to a wire. In this mode, only one electrode is fixed, while the other triboelectric material is free to move (e.g., a finger tapping, clothing rustling). This simplifies integration into clothing or accessories. For a mask, this mode could be used to harvest energy from jaw movements against a stationary electrode near the ear loop. While its output is generally lower than dual-electrode modes, its ease of use is a major benefit.

What Power Management Circuits Are Critical for Usability?

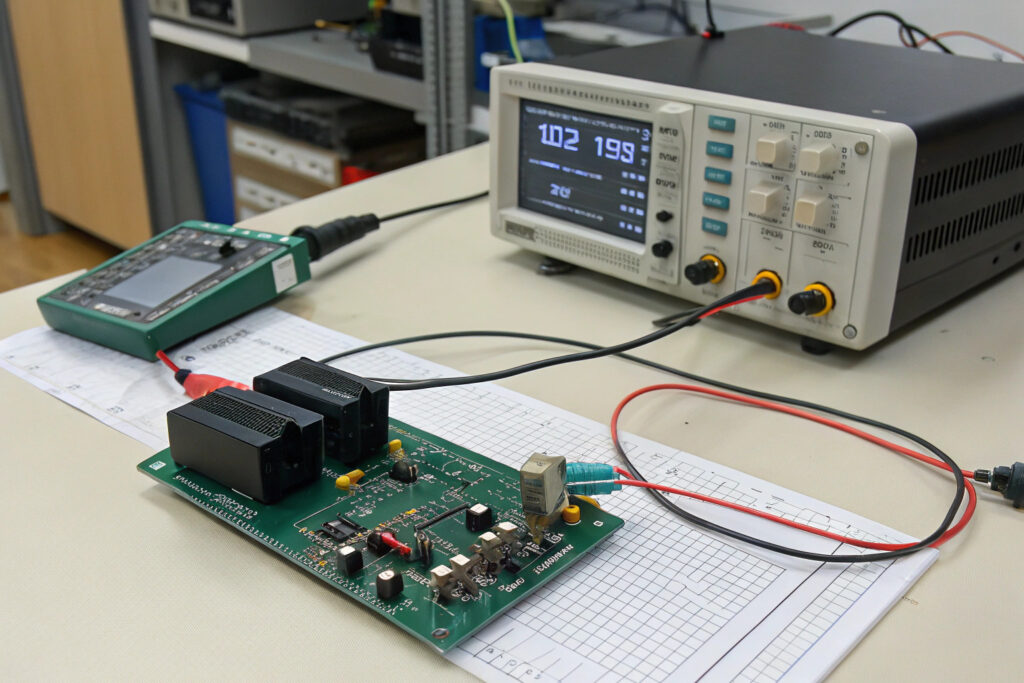

The raw output of a TENG—high voltage (hundreds of volts), low current (microamps), and pulsed AC—is incompatible with powering standard electronics (3.3V or 5V DC). A sophisticated power management unit (PMU) is therefore not an accessory but the core of a usable TENG power source.

How is High Voltage Efficiently Stepped Down?

Directly stepping down hundreds of volts with a linear regulator is extremely inefficient. The standard solution involves:

- Rectification: A full-wave bridge rectifier converts the AC output to pulsed DC.

- Voltage Multiplication/Transformation: A charge pump circuit (like a Cockcroft-Walton multiplier) can be used in reverse—not to multiply voltage, but to transform the high-voltage, low-charge pulses into lower-voltage, higher-charge packets, improving impedance matching.

- Switching Conversion: A high-efficiency buck converter or a specialized transformer-coupled circuit then steps the voltage down to the target level (e.g., 3.3V) with minimal loss.

Research from institutions like the Georgia Tech Institute for Electronics and Nanotechnology shows that optimized PMUs can achieve over 60% end-to-end efficiency from TENG raw output to stored energy.

What Energy Storage Buffers the Intermittent Supply?

TENGs generate power only during motion. To run a continuous sensor or transmit data wirelessly, energy must be stored. The choice depends on the application:

- Supercapacitors: Ideal for high cycle life (millions of cycles) and rapid charging. They are perfect for smoothing out the pulsed TENG output to power sensors with moderate energy needs. A 10-100 mF supercapacitor is typical.

- Thin-Film Lithium Batteries: Offer higher energy density for applications needing to store energy over longer periods (e.g., to power a Bluetooth transmission burst). They are rechargeable but have fewer cycles than supercapacitors.

The best systems often use a hybrid approach: a supercapacitor for immediate smoothing and a small battery for longer-term storage and peak power delivery.

How Can TENGs Be Effectively Integrated into Smart Masks?

The ultimate test of a "best" TENG source is its successful, unobtrusive integration into a functional, comfortable product. The design must harvest energy without hindering the primary function of the mask.

Where on a Mask is Mechanical Energy Most Abundant?

Strategic placement is key to maximizing harvestable energy:

- Cheek/Chin Area: Experiences the largest deformation during talking, chewing, and breathing. Ideal for contact-separation mode TENGs that flex with the mask material.

- Near the Exhalation Valve: High-velocity airflow from exhalation can be used to drive a flutter-based or rotary TENG.

- Ear Loop/Jaw Hinge Area: Subject to stretching and friction during jaw movement, suitable for stretchable TENGs or single-electrode mode harvesting.

Our integration focuses on the cheek area using a breath-responsive, multi-layer TENG that adds minimal weight and maintains mask flexibility.

How Are Durability and Washability Ensured?

A wearable TENG must survive sweat, humidity, and cleaning. Key strategies include:

- Encapsulation: Sealing the active TENG layers and electrodes within a breathable but waterproof membrane (e.g., ePTFE).

- Robust Electrodes: Using conductive textiles, stretchable silver nanowire networks, or laser-induced graphene instead of brittle metal films.

- Stable Material Pairings: Selecting polymers whose triboelectric properties do not degrade significantly with humidity (e.g., certain fluorinated polymers).

Accelerated testing simulating months of use and multiple gentle wash cycles is essential to validate the design.

Conclusion

The "best" TENG power source is a holistic system tailored to its application. For smart masks, it combines a high-output, flexible material pair (like nanostructured PDMS and conductive nylon) operating in a suitable mode (like contact-separation for breathing). It is governed by an efficient power management circuit that rectifies, transforms, and stores energy in a supercapacitor or hybrid storage buffer. Most importantly, it is seamlessly and durably integrated into the mask without compromising protection or comfort. As material science and circuit design advance, TENGs are poised to become the cornerstone of truly self-sustaining wearable electronics.

Ready to explore integrating triboelectric nanogenerators into your next-generation smart masks or wearables? Contact our Business Director, Elaine, at elaine@fumaoclothing.com to discuss how we can co-develop or supply advanced energy-harvesting solutions that power your innovation.