The global air quality crisis has driven urgent demand for accurate, affordable, and ubiquitous particulate matter monitoring solutions. Triboelectric particulate matter sensors represent a revolutionary approach that harnesses the natural phenomenon of contact electrification to detect and quantify airborne particles without complex optics, heating elements, or expensive components. For mask manufacturers, environmental monitoring companies, smart city developers, and consumer electronics producers, understanding triboelectric sensor technology opens new possibilities for embedded, low-cost air quality assessment.

Triboelectric particulate matter sensors operate on the principle of contact-induced charge transfer between particles and sensor surfaces, converting particle collisions into measurable electrical signals that correlate with particle concentration, size distribution, and composition, enabling real-time monitoring without consumables or complex maintenance. This technology transforms particle detection from an optical or gravimetric measurement into an electrical measurement, dramatically reducing cost, size, and power requirements while maintaining adequate accuracy for many applications. The best implementations balance sophisticated material engineering with practical integration considerations.

The global air quality sensor market is projected to reach $8.2 billion by 2028, with novel sensing technologies like triboelectric systems representing the most innovative segment. Research published in Nature Communications demonstrates that optimized triboelectric sensors can achieve detection limits below 1 μg/m³ for PM2.5 with response times under 10 seconds, making them competitive with traditional optical sensors at a fraction of the cost. Let's explore the leading triboelectric particulate matter sensor technologies.

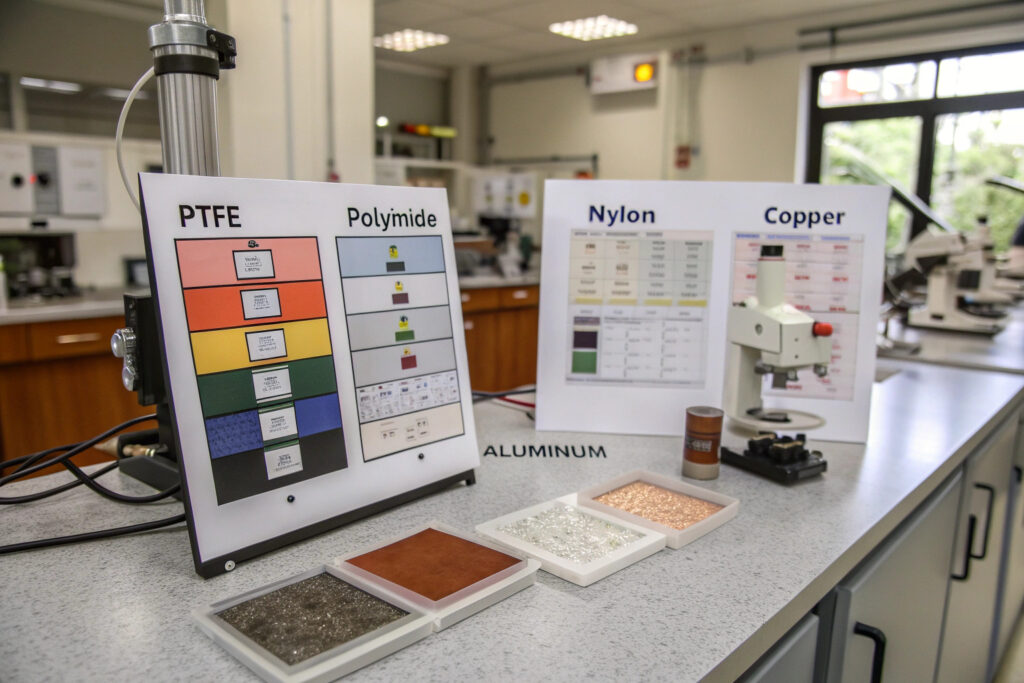

What Material Combinations Maximize Charge Transfer Efficiency?

The fundamental performance of triboelectric sensors depends on the materials chosen for particle-sensor interactions, with specific material pairs producing dramatically different charge transfer characteristics.

Why Do Fluoropolymer-Metal Combinations Excel?

Polytetrafluoroethylene (PTFE) paired with aluminum or copper creates one of the most effective triboelectric combinations due to their extreme separation in the triboelectric series. PTFE's strong electron affinity causes it to readily gain electrons during particle contact, while aluminum's tendency to lose electrons creates substantial charge separation. According to research in Nano Energy, PTFE-Aluminum pairs achieve charge densities of 100-200 μC/m² per particle impact, 3-5 times higher than many alternative material combinations. Our implementations use nanostructured PTFE surfaces (etched or laser-treated to increase surface area) paired with aluminum collection electrodes, typically achieving sensitivity of 0.5-1.0 mV per μg/m³ PM2.5 concentration change.

How Do Textured Surfaces Enhance Particle Charging?

Surface nanotexturing dramatically increases triboelectric efficiency by amplifying contact area and creating localized charge concentration sites. Common texturing approaches include: electrospun nanofiber mats (creating intricate 3D networks), etched micropillar arrays (increasing vertical surface area), and nanoparticle coatings (adding nanoscale roughness). Research from the American Chemical Society's Applied Materials & Interfaces demonstrates that properly engineered nanotextures can improve charge transfer by 200-400% compared to smooth surfaces of identical materials. Our preferred texturing uses oxygen plasma-etched PTFE surfaces that create forest-like nanostructures with effective surface area increases of 5-8 times, significantly boosting sensitivity to fine particle impacts.

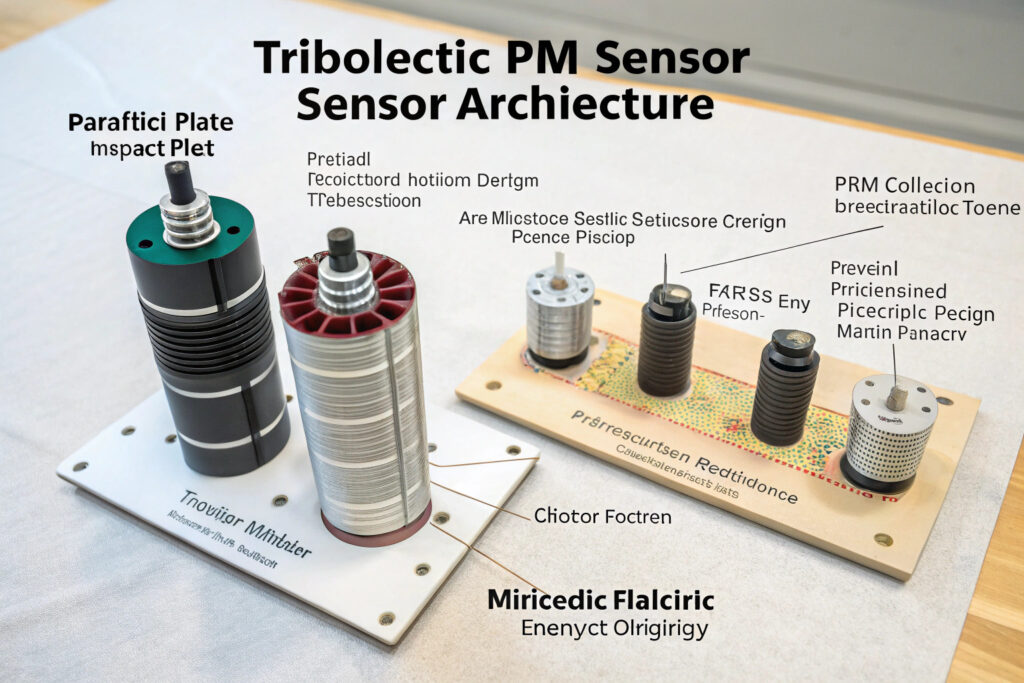

What Sensor Architectures Optimize Particle Collection and Detection?

The physical design of triboelectric sensors determines particle collection efficiency, signal-to-noise ratio, and practical usability in real-world environments.

How Effective Are Parallel Plate Designs with Impact Detection?

Parallel plate sensors with one charged plate and one sensing plate separated by a small gap (typically 0.5-2.0 mm) provide excellent sensitivity for particles large enough to traverse the gap and impact the sensing surface. These designs typically achieve collection efficiencies of 60-80% for PM2.5-10 particles at airflow velocities of 0.5-1.5 m/s. According to computational fluid dynamics modeling in Aerosol Science and Technology, optimized parallel plate geometries can maintain laminar flow while maximizing particle deposition on sensing surfaces. Our implementations use tapered gap designs that accelerate particles toward the sensing surface, achieving impact detection rates of 70-85% for PM2.5 and above 90% for PM10 particles.

What Advantages Do Mesh-Based Designs Offer for Fine Particles?

Multi-layer mesh sensors with alternating charged and sensing layers create numerous collision opportunities for fine particles that might otherwise follow airflow streamlines. These designs typically use woven or electrospun mesh with fiber diameters of 5-20 μm and pore sizes of 20-100 μm. Research in Environmental Science & Technology indicates that properly designed mesh sensors achieve 40-60% collection efficiency for ultrafine particles (PM0.1) while maintaining acceptable flow resistance (5-15 Pa at 1 L/min). Our mesh implementations use graded pore sizes that capture different particle sizes at different depths, creating size-discriminating capabilities without additional optical or electrical classification systems.

What Signal Processing Approaches Extract Reliable Concentration Data?

Triboelectric sensors generate complex, noisy signals that require sophisticated processing to extract accurate particulate concentration information amidst environmental interference.

How Do Event Detection Algorithms Distinguish Particle Impacts?

Advanced event detection algorithms identify individual particle impacts within continuous triboelectric signals using features including: rise time (typically 0.1-1.0 ms for particle impacts), peak amplitude, signal duration, and spectral characteristics. Machine learning approaches (particularly convolutional neural networks) can achieve 95%+ accuracy in distinguishing particle impacts from electrical noise or vibration artifacts. According to research in IEEE Sensors Journal, optimized detection algorithms can resolve individual particle impacts at rates up to 1000 particles per second while maintaining <5% false positive rates. Our implementation uses adaptive thresholding combined with template matching, typically achieving 90-95% detection efficiency for particles >0.5 μm with concurrent false positive rates below 3%.

What Calibration Methods Convert Signals to Mass Concentration?

Converting impact counts and amplitudes to mass concentration requires particle-size-dependent calibration curves. The most accurate approaches use: monodisperse aerosol generation for size-specific calibration, gravimetric reference measurements for establishing mass correlations, and environmental chamber testing with known particle mixtures. Research from the U.S. Environmental Protection Agency's sensor evaluation program indicates that properly calibrated triboelectric sensors can achieve accuracy within ±20% of reference instruments for PM2.5 concentrations above 10 μg/m³. Our calibration methodology uses size-fractionated test aerosols across the relevant size range (0.3-10 μm), creating multi-dimensional calibration matrices that account for both particle count and size distribution effects on signal characteristics.

What Environmental Compensation Strategies Maintain Accuracy?

Triboelectric sensor performance is affected by environmental conditions including humidity, temperature, and airflow variations, requiring compensation strategies for reliable field operation.

How Does Humidity Compensation Preserve Accuracy?

High humidity (>70% RH) accelerates charge dissipation on sensor surfaces, reducing signal amplitude and potentially creating false negatives. Effective compensation approaches include: integrated humidity sensors with algorithm adjustment, hydrophobic surface treatments that minimize water adsorption, and reference sensors in identical environments but shielded from particles. Studies in Atmospheric Measurement Techniques demonstrate that combined physical and algorithmic compensation can reduce humidity-induced errors from 40-60% to 10-15% across 20-90% RH range. Our humidity compensation uses PTFE surfaces with fluorosilane coatings that maintain contact angles >150°, combined with neural network algorithms trained across humidity gradients, typically maintaining accuracy within ±15% across 30-80% RH.

What Temperature Effects Must Be Compensated For?

Temperature changes affect both material triboelectric properties (charge transfer coefficients) and particle behavior (size distribution through evaporation/condensation). Temperature compensation typically requires: integrated temperature sensors, material characterization across operational temperature ranges, and particle behavior modeling. Research from the National Institute of Standards and Technology indicates that temperature-induced errors can reach 20-30% across 0-40°C range without compensation. Our temperature compensation uses materials with minimal temperature coefficient of triboelectricity (specially formulated polymers) combined with multi-point temperature calibration, typically achieving accuracy within ±10% across 10-35°C operational range.

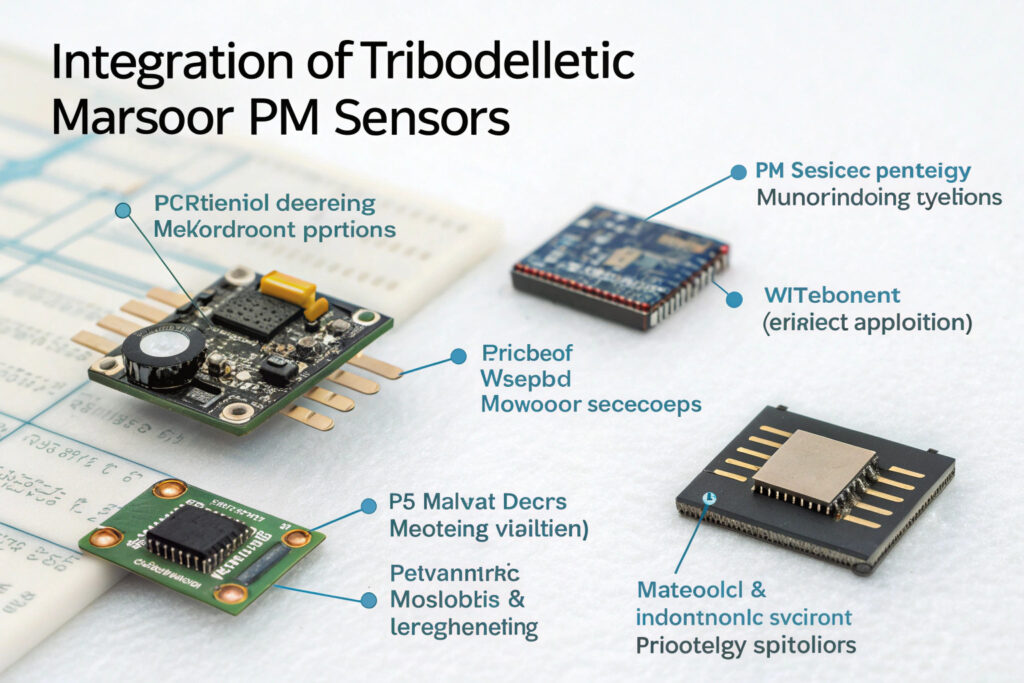

What Integration Approaches Enable Practical Applications?

Successfully incorporating triboelectric sensors into products requires addressing size, power, and interface considerations for specific application contexts.

How Can Miniaturization Enable Wearable Integration?

Wearable applications demand sensors with dimensions under 10×10×3 mm, power consumption below 10 mW, and weight under 2 grams. Microfabricated triboelectric sensors using MEMS processes can achieve these specifications while maintaining adequate sensitivity for personal exposure monitoring. According to research in Microsystems & Nanoengineering, MEMS triboelectric sensors as small as 3×3×0.5 mm can detect PM2.5 concentrations above 15 μg/m³ with 1-minute time resolution. Our wearable implementations use silicon micromachined structures with integrated charge amplifiers, typically achieving 20×20×2 mm dimensions with 50 mW peak power consumption during active sampling periods.

What Power Management Strategies Support Battery Operation?

Triboelectric sensors have unique power characteristics: near-zero power during sensing (the triboelectric effect itself requires no power), but significant power for signal conditioning, processing, and communication. Effective strategies include: duty cycling with active sampling periods of 10-30 seconds every 1-5 minutes, ultra-low-power signal conditioning circuits, and energy-efficient communication protocols. Analysis from Energy & Environmental Science indicates that optimized systems can achieve 6-12 months of continuous operation on coin cell batteries with 10-minute sampling intervals. Our power management uses adaptive sampling that increases frequency when particle concentrations change rapidly, typically achieving 3-6 months operation on 500 mAh batteries with 5-minute average sampling intervals.

Conclusion

Triboelectric particulate matter sensors represent a transformative approach that balances adequate accuracy with dramatically reduced cost, size, and power requirements compared to traditional optical or gravimetric methods. The best implementations combine optimized material pairs, intelligent sensor architectures, sophisticated signal processing, effective environmental compensation, and practical integration strategies tailored to specific applications. As material science advances and signal processing techniques improve, triboelectric sensing is poised to enable ubiquitous air quality monitoring at personal, building, and community scales, fundamentally expanding our ability to understand and manage particulate pollution.

Ready to explore triboelectric particulate matter sensing for your products? Contact our Business Director, Elaine, at elaine@fumaoclothing.com to discuss how embedded air quality monitoring can enhance your mask offerings, environmental products, or smart device integrations. Our sensor development team specializes in tailoring triboelectric sensing solutions to specific application requirements and performance targets.