In emergency scenarios like power outages, smoke-filled rooms, or maritime disasters, traditional battery-powered lighting can fail, leaving individuals in dangerous darkness. Triboluminescence—light generated through mechanical action like crushing, rubbing, or fracturing certain materials—offers a fail-safe, battery-free emergency lighting solution. For mask and safety equipment manufacturers, integrating this passive, on-demand illumination can provide critical visibility when electronic systems are compromised, enhancing user safety in life-threatening situations.

The best triboluminescent emergency lighting systems combine high-intensity, persistent luminescence with robust mechanical activation, environmental stability, and safe integration into wearable formats, typically achieved through optimized crystal/polymer composites or advanced surface coatings that convert mechanical stress into visible light without external power sources. These systems transform routine mechanical actions—such as pulling a mask strap, breaking a sealed panel, or striking a surface—into immediate, reliable light sources, functioning as the ultimate backup when all else fails.

The global emergency lighting market exceeds $7 billion, with growing interest in passive safety systems for industrial, marine, and personal protective equipment. Triboluminescent materials, while known for centuries, have seen recent breakthroughs in brightness, duration, and practicality. For a mask, this could mean integrated lighting strips that glow when the mask is deployed in darkness or straps that illuminate when pulled during donning. Identifying the optimal system requires evaluating material composition, activation mechanisms, and integration durability.

What Material Compositions Deliver Maximum Brightness and Duration?

The core of any triboluminescent system is the material that converts mechanical energy into photons. Not all triboluminescent materials are created equal; significant differences exist in intensity, color, and afterglow duration.

Why Do Doped Zinc Sulfide Composites Lead in Wearable Applications?

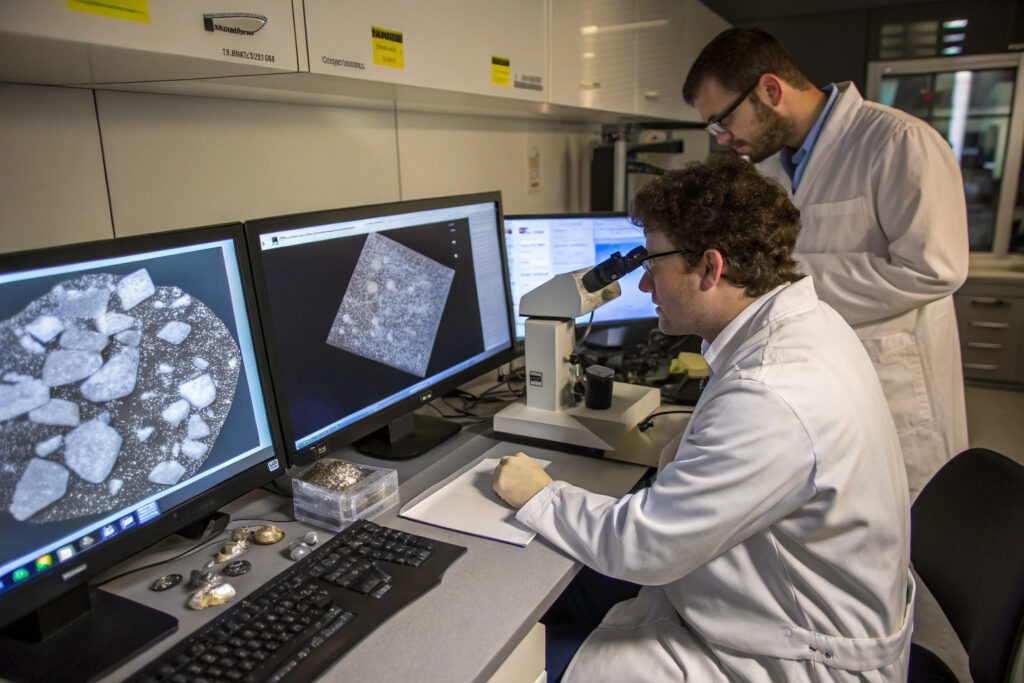

While simple sugar (sucrose) crystals exhibit triboluminescence, their intensity is low. The current benchmark for practical applications is europium-doped zinc sulfide (ZnS:Eu) embedded in a transparent polymer matrix (e.g., epoxy or silicone). When the composite is stressed, micro-fractures in the ZnS crystals generate intense flashes of orange-red light. Researchers at the University of Georgia have developed polymer composites where ZnS:Eu particles are aligned to maximize light output upon bending or impact. For mask integration, a flexible silicone strip doped with these particles can be bent or struck to produce over 100 millicandelas of light for several seconds—sufficient to locate a mask in total darkness or illuminate a small area. The key sourcing specification is the particle loading percentage and dispersion uniformity within the polymer.

Are There Brighter, Next-Generation Alternatives?

Emergent materials show even greater promise. Lanthanide complexes, such as tetrakis(dibenzoylmethanato)europium, when mixed with polymer hosts, can produce flashes up to 10 times brighter than ZnS:Eu but are more sensitive to moisture and degradation. Metal-Organic Frameworks (MOFs) engineered for triboluminescence offer tunable colors and potentially longer afterglow through phosphorescent mechanisms. Papers in Advanced Optical Materials detail MOFs that emit bright blue or green light upon shear stress. For emergency applications where color differentiation is important (e.g., red for "stop," green for "go"), these tunable systems are superior. However, their cost and environmental stability must be evaluated for mass-produced safety gear.

How Are Activation Mechanisms Optimized for Emergency Use?

The system must be intuitively activated under duress, with minimal force and clear user feedback. The mechanical design of the activation interface is as important as the material itself.

What Peel-and-Light Systems Work for Mask Integration?

A highly effective mechanism for masks is the peel-and-light strip. A protective opaque layer covers a triboluminescent polymer film. In an emergency, the user peels this layer away; the act of peeling creates sufficient shear and tensile stress at the adhesive interface to activate the material, causing the freshly exposed strip to glow. This is ideal for marking escape routes on mask straps or highlighting critical components like exhalation valves in the dark. The design challenge is ensuring the peeling force is consistent and that the adhesive does not contaminate or deactivate the luminescent material. Our prototyping uses a calibrated release liner and a pressure-sensitive adhesive formulated to maximize shear stress upon removal.

Can Integrated "Breakable" Components Provide Instant Light?

For more immediate, brighter flashes, integrated frangible capsules can be embedded. A small, brittle capsule containing triboluminescent crystals is placed within a flexible mask component (e.g., within a thickened tab on the nose bridge). When the tab is deliberately snapped or crushed between fingers, the capsule fractures, producing a bright flash. This is analogous to a chemical light stick but purely mechanical. Sourcing involves finding suppliers who can produce consistent, small-scale glass or brittle polymer capsules with precise wall thickness to control breakage force. The system must be designed to contain crystal dust after fracture, preventing inhalation—often achieved by sealing the capsule within a secondary, transparent silicone pouch.

What Are the Integration and Durability Challenges?

Triboluminescent materials are often sensitive to moisture, oxygen, and UV degradation. Integrating them into a product meant for harsh environments and long shelf life requires protective strategies.

How Do Encapsulation Techniques Protect Sensitive Materials?

The primary threat to materials like ZnS:Eu is oxidation and hydrolysis, which quench their luminescent properties. Multi-layer encapsulation is essential:

- Primary Encapsulation: Each luminescent particle is coated with a thin, inert silica layer via sol-gel processes.

- Secondary Encapsulation: The particle/polymer composite is itself sealed within an oxygen- and moisture-impermeable barrier film, such as a thin aluminum oxide (AlOx) coating applied via atomic layer deposition (ALD) or a laminated polyester/aluminum/polyethylene film.

These techniques, borrowed from food packaging and OLED display industries, can extend the functional shelf life of the system to over 10 years. Suppliers should provide accelerated aging data (e.g., 85°C/85% relative humidity testing) correlating to real-world shelf life.

How is Mechanical Fatigue Prevented in Flexible Components?

In a peel-and-light strip or a bendable component, repeated minor stresses during normal use (not intentional activation) could cause premature, weak light emission or degrade the final bright output. This is prevented by designing a clear activation threshold. Using polymer matrices with a specific modulus (stiffness), the composite remains inert under normal flexing but will fracture and luminesce only when a specific, higher strain is applied (e.g., a sharp bend over a small radius). Finite element analysis (FEA) simulation during design can model stress distributions to ensure the threshold is appropriate. Sourcing involves verifying that the material supplier can consistently meet the specified mechanical threshold in production.

How Do Performance Metrics Compare to Traditional Solutions?

Triboluminescent systems are not meant to replace LEDs or chemical light sticks for primary illumination but to serve as a zero-power, ultra-reliable backup. Their performance must be evaluated on appropriate metrics.

What is the Realistic Light Output and Duration?

The best current triboluminescent composites can produce an initial flash exceeding 100-300 millicandelas (mcd), decaying to a useful afterglow (>1 mcd) for 30-90 seconds. This is sufficient to read nearby labels, identify a door handle, or signal one's location at close range. In contrast, a single low-power LED might produce 5,000-10,000 mcd but requires a functioning battery. A chemical light stick (cyalume) produces thousands of mcd for hours but is a single-use, consumable item that can degrade over time in storage. The triboluminescent system's value is its infinite shelf life and guaranteed function upon mechanical demand.

How Does Reliability in Extreme Conditions Compare?

This is where triboluminescence excels. Unlike batteries which fail in extreme cold or lose charge over time, and unlike chemiluminescent sticks which can degrade if frozen or overheated, a properly encapsulated triboluminescent material is inherently stable across a vast temperature range (-40°C to +85°C). It is also immune to electromagnetic interference (EMI) and water immersion (if sealed). This makes it ideal for safety equipment stored in vehicles, maritime life vests, or industrial emergency kits where environmental conditions are uncontrolled and reliability is paramount. Standards such as MIL-STD-810 for environmental engineering can be used to benchmark this reliability.

Conclusion

The best triboluminescent emergency lighting systems for integration into masks and PPE are robust, user-activated material composites—primarily doped zinc sulfide in engineered polymer matrices—protected by advanced encapsulation and designed with intuitive mechanical triggers like peeling or snapping. They offer a unique value proposition: absolutely reliable, instant light with no power source, no shelf-life degradation, and functionality in the most extreme conditions. While not as bright or long-lasting as active electronics, they serve as the critical, fail-safe illumination when every other system has failed.

Ready to enhance the safety profile of your mask or protective equipment with fail-safe triboluminescent lighting? Contact our Business Director, Elaine, at elaine@fumaoclothing.com. Our team can help you source, test, and integrate the most advanced passive lighting systems to create products that protect even when the lights go out.