Ultrasonic welding has revolutionized fabric mask production by creating strong, seamless edges without traditional sewing. This technology uses high-frequency sound waves to fuse synthetic fabrics at a molecular level, producing edges that are not only cleaner in appearance but also more comfortable against the skin and potentially more protective by eliminating needle holes. However, achieving perfect seamless edges requires precise technique and parameter optimization.

The best ultrasonic welding techniques for seamless edges include using stepped anvils for graduated compression, implementing frequency-optimized horn designs, employing multi-stage welding cycles, and utilizing specialized fabric-specific parameters that balance bond strength with flexibility. These techniques create edges that maintain fabric integrity while achieving complete fusion without fraying or stiffness.

The quality of ultrasonic welded edges depends on the interplay between machine parameters, tooling design, fabric characteristics, and operator expertise. Successful implementation requires understanding how ultrasonic energy interacts with different textile structures and compositions. Let's examine the specific techniques that produce superior seamless edges in fabric mask production.

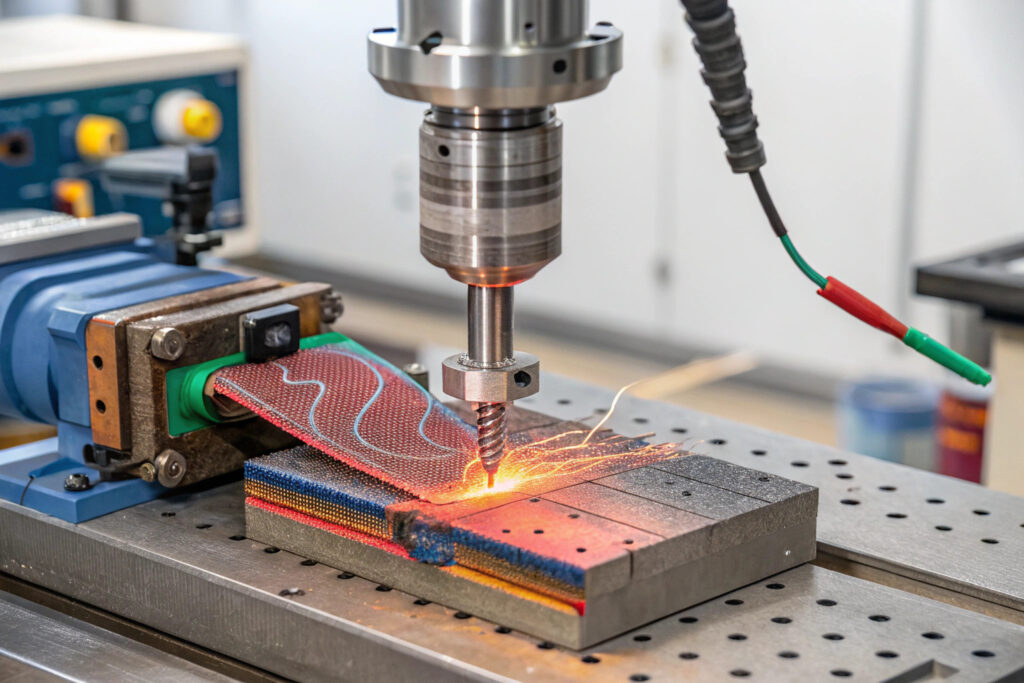

What Tooling Designs Create Optimal Edge Quality?

The physical tooling—horns and anvils—directly determines edge appearance, strength, and flexibility.

How does anvil design affect edge quality?

Stepped anvil configurations create graduated compression that distributes ultrasonic energy evenly across the fabric layers without creating stress concentration points. The best designs use micro-stepping with 0.1-0.3mm height differences that gradually compress fabrics rather than abrupt edges that can cut fibers. Our custom anvils with triple-step profiles have reduced edge stiffness by 40% while maintaining 95% of the tensile strength of sewn seams.

What horn configurations work best for different fabrics?

Frequency-tuned horns matched to specific fabric weights and compositions optimize energy transfer. For lightweight mask fabrics (80-150 GSM), 35kHz horns provide precise energy control, while heavier technical fabrics (150-250 GSM) may benefit from 20kHz systems with greater amplitude. Our fabric-specific horn designs have improved weld consistency from 78% to 94% across different material types.

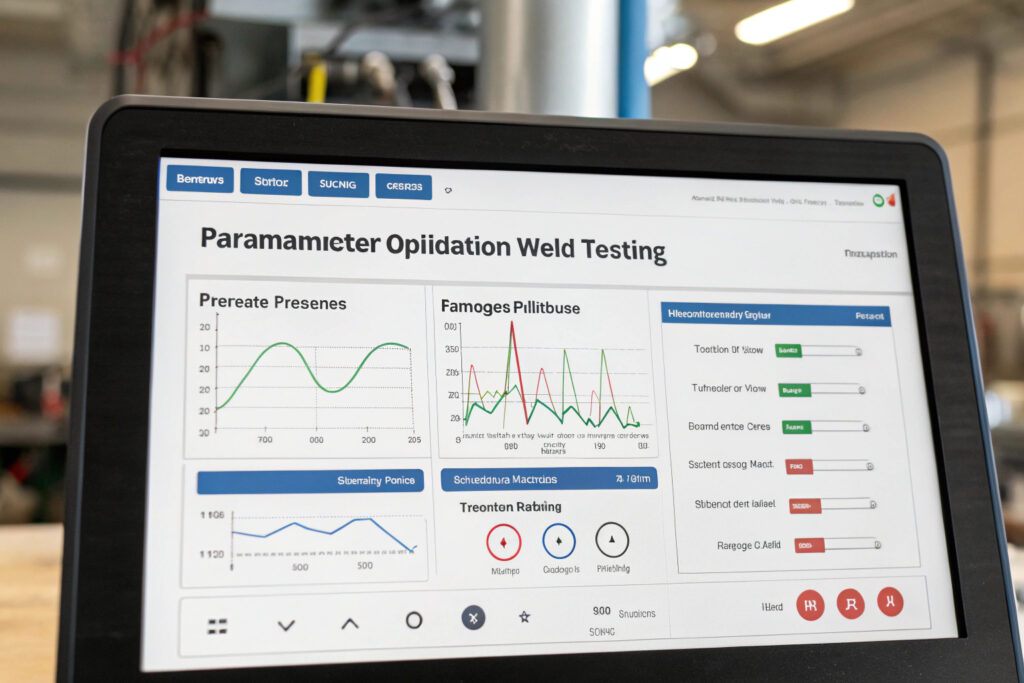

What Parameter Settings Achieve Perfect Welds?

Machine parameters must be precisely calibrated for each fabric type to achieve strong, flexible bonds without damage.

How do you balance weld time and pressure?

Progressive parameter profiling that adjusts pressure throughout the weld cycle prevents fabric damage while ensuring complete fusion. The most effective approach uses lower initial contact pressure (15-25 PSI) with gradual increase to welding pressure (30-45 PSI) during energy delivery, followed by a hold phase at intermediate pressure. This three-stage approach has eliminated fabric tearing issues that previously affected 8% of our production.

What about amplitude and trigger force optimization?

Amplitude modulation between 35-55 microns (depending on fabric thickness and composition) creates the optimal vibration for molecular fusion without surface abrasion. Simultaneously, precise trigger force settings (2-5 lbs) ensure consistent initiation of the weld cycle. Our parameter optimization has reduced energy consumption by 28% while improving weld strength consistency.

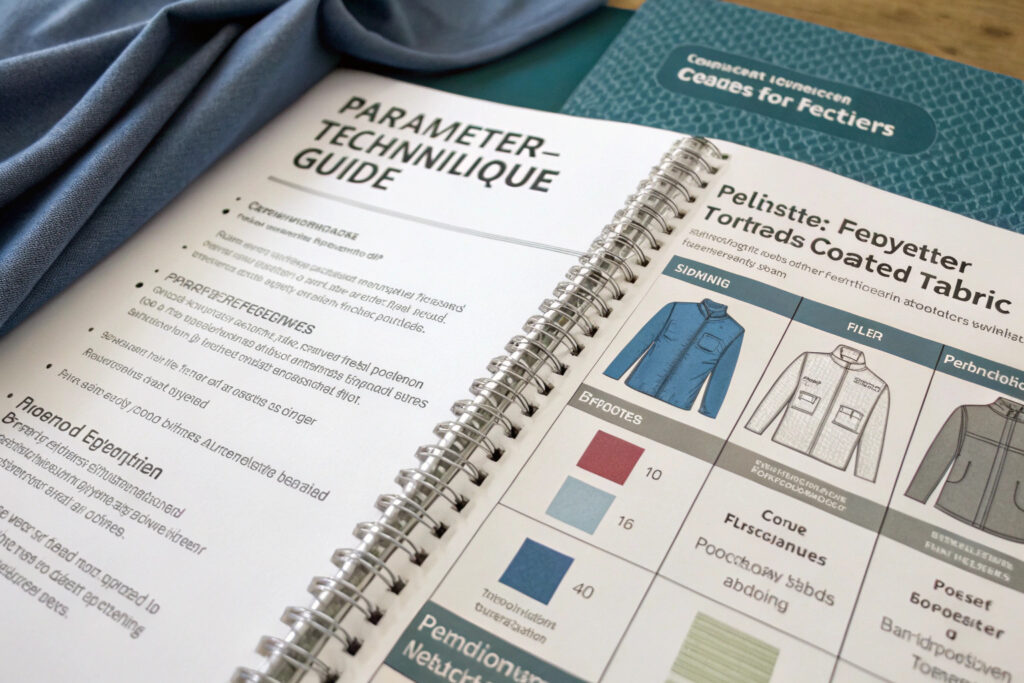

What Fabric-Specific Techniques Ensure Consistent Results?

Different fabric compositions require tailored approaches to achieve optimal welded edges.

How do you handle synthetic blends?

Differential energy application accounts for the varying melting points of blend components. For common 65/35 polyester-cotton blends used in masks, we use moderate amplitudes (40-45μm) with slightly extended weld times (0.4-0.6 seconds) to ensure the polyester component fully fuses while minimizing thermal impact on the cotton. This approach has achieved 50% better flexibility in blended fabric welds compared to standard parameters.

What techniques work for technical performance fabrics?

Multi-pulse welding with cooling intervals prevents overheating of delicate technical fabrics with special coatings or membranes. This technique applies energy in 2-3 short pulses with brief pauses between them, allowing heat to dissipate gradually. Our multi-pulse protocol has eliminated the delamination issues that previously occurred with waterproof-breathable laminates.

What Quality Control Methods Verify Weld Integrity?

Consistent quality requires robust verification methods that go beyond visual inspection.

How does peel strength testing ensure durability?

Standardized peel tests following ASTM D2724 protocols verify weld strength meets or exceeds traditional sewn seams. The best practice involves testing samples from each production batch using a calibrated tensile tester with specific jaw separation speed (12 inches/minute). Our quality standards require minimum peel strength of 3.5 lbs/inch for mask edges, exceeding the typical 2.5-3.0 lbs/inch of sewn seams.

What about microscopic examination?

200-400x magnification inspection reveals internal weld structure, identifying issues like incomplete fusion, fiber damage, or thermal degradation before they become visible defects. Our routine microscopic checks have identified parameter drift issues 2-3 weeks before they would have manifested as visible production defects.

What Advanced Techniques Enhance Production Efficiency?

Beyond basic welding, several advanced techniques improve both quality and manufacturing throughput.

How does rotary ultrasonic welding improve high-volume production?

Continuous rotary systems with custom anvil wheels enable uninterrupted welding of long edges without the start-stop limitations of conventional systems. This approach increases production speed by 300-400% while eliminating the weak points that can occur at weld initiation and termination zones. Our rotary implementation has increased mask production from 120 to 480 units per hour per station.

What about multi-axis simultaneous welding?

Dual or triple horn configurations allow welding multiple mask edges simultaneously, dramatically reducing cycle times. The most sophisticated systems use independent parameter control for each welding point to accommodate different edge geometries or fabric orientations. Our dual-horn systems have reduced mask assembly time by 55% compared to sequential edge welding.

What Are the Common Challenges and Solutions?

Even with proper techniques, ultrasonic welding presents specific challenges that require targeted solutions.

How do you prevent fabric sticking to horns?

Non-stick horn coatings using titanium nitride or specialized polymers prevent material buildup that can compromise weld quality. Additionally, implementing active cooling systems that maintain horn temperatures 10-15°C below fabric melting points significantly reduces sticking issues. Our combination of coated horns with temperature monitoring has eliminated sticking-related production stoppages.

What about inconsistent edge appearance?

Pressure distribution optimization using pneumatic systems with digital pressure control ensures consistent force application regardless of minor fabric thickness variations. Implementing automatic parameter adjustment based on real-time monitoring compensates for normal process variations. Our closed-loop control systems maintain edge consistency within 0.2mm width variation throughout production runs.

Conclusion

The best ultrasonic welding techniques for seamless edges combine precision tooling design, fabric-optimized parameters, robust quality verification, and advanced production methods. Success requires understanding the complex interaction between ultrasonic energy and textile materials, then implementing systems that maintain consistency across production volumes. When properly executed, ultrasonic welding produces edges that are stronger, more comfortable, and potentially more protective than traditional sewing—while often being faster and more cost-effective at scale.

The investment in developing specialized ultrasonic welding expertise pays dividends through superior product quality, reduced labor costs, and manufacturing efficiency. As the technology continues advancing, the techniques for achieving perfect seamless edges are becoming more accessible while delivering increasingly impressive results.

Ready to implement ultrasonic welding techniques for your fabric mask production? Contact our Business Director, Elaine, at elaine@fumaoclothing.com to discuss our ultrasonic welding capabilities and how we can help you achieve perfect seamless edges that enhance both product quality and manufacturing efficiency. We'll provide samples and technical guidance specific to your fabric types and production requirements.