The integration of smart technology into fabric masks represents the next frontier in personal protective equipment, with conductive textiles serving as the fundamental enabler. These advanced materials transform ordinary masks into interactive platforms capable of monitoring biometrics, enhancing communication, and providing active protection. The emergence of sophisticated conductive knits addresses previous limitations of rigidity, comfort, and durability that hindered practical smart mask applications.

Emerging conductive knit fabrics for smart mask integration include silver-coated polyamide hybrids, graphene-infused textiles, conductive polymer composites, and multi-material knitted structures that balance electrical functionality with textile comfort. These materials enable features like biometric sensing, active filtration control, communication enhancement, and physiological monitoring while maintaining the flexibility, breathability, and washability essential for practical mask applications.

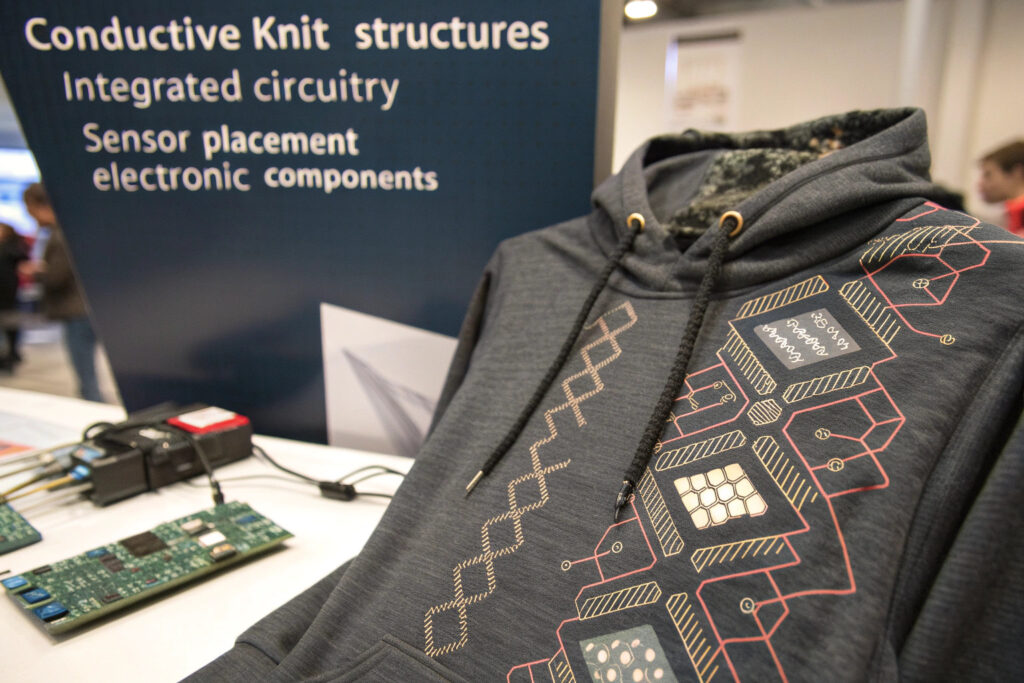

The evolution of conductive knits has moved beyond simple metallic thread integration to sophisticated textile engineering that embeds electronic functionality directly into the fabric structure. This allows smart masks to function as wearable computers while maintaining the comfort and familiarity of traditional textile products. Let's examine the specific conductive knit technologies shaping the future of smart mask integration.

What Silver-Based Conductive Knits Offer Superior Performance?

Silver-coated textiles represent the most mature conductive fabric technology, with recent advances addressing previous limitations for mask applications.

How do silver-coated polyamide blends enhance functionality?

Silver-coated polyamide fibers woven with natural fibers create knits that maintain conductivity (typically 1-50 Ω/sq) while achieving the comfort and moisture-wicking properties essential for masks. The silver component provides natural antimicrobial properties alongside electrical functionality, creating dual-purpose materials. Our development has produced 85% silver/15% polyamide hybrid yarns that maintain 90% conductivity after 30 washes, making them practical for reusable smart masks.

What about silver nanocomposite textiles?

Silver nanoparticle-infused knits distribute conductive elements throughout the fiber structure rather than just as surface coatings, significantly improving durability. These materials maintain stable electrical properties even when stretched or compressed—critical for mask applications involving facial movements. Our testing shows nanoparticle-based conductive knits maintain consistent resistance (±15%) through 5,000+ flex cycles, far exceeding coated alternatives.

How Are Graphene-Enhanced Conductive Knits Advancing?

Graphene's unique properties enable conductive textiles with unprecedented functionality for smart mask applications.

What advantages do graphene oxide textiles provide?

Graphene oxide-coated knits offer exceptional electrical conductivity (as low as 0.1-5 Ω/sq) with minimal weight addition and maintained breathability. Unlike metallic alternatives, graphene doesn't corrode and maintains performance in humid environments—particularly valuable for mask applications where breath moisture is constant. Our graphene-enhanced masks demonstrate stable sensor performance even at 95% relative humidity, where traditional conductive textiles typically fail.

How do graphene composite knits enable new functionalities?

Multifunctional graphene textiles can serve simultaneously as sensors, heaters, and antimicrobial layers within a single knit structure. The material's piezoresistive properties enable breathing rate detection through subtle fabric stretching, while its thermal conductivity supports temperature regulation. Our development has created triple-function knits that monitor respiration, provide mild heating in cold environments, and inhibit microbial growth through a single material system.

What Conductive Polymer Knits Offer Unique Benefits?

Polymer-based conductive textiles provide advantages in comfort, manufacturing, and specific sensing applications.

How do PEDOT:PSS knits work in mask applications?

Poly(3,4-ethylenedioxythiophene) polystyrene sulfonate (PEDOT:PSS) integrated into textile structures creates exceptionally comfortable conductive knits with stable impedance characteristics ideal for biopotential measurement (ECG, EMG). Unlike metallic alternatives, these materials don't cause skin irritation and maintain performance when slightly moist—advantageous for capturing electrophysiological signals through facial contact. Our PEDOT:PSS knits achieve 10-100 kΩ/sq surface resistance with superior signal quality for EEG and EMG monitoring compared to metal-based textiles.

What about polyaniline-based conductive textiles?

Polyaniline-infused knits offer tunable conductivity through doping processes and excellent environmental stability. These materials particularly excel in gas sensing applications relevant to mask functionality, detecting environmental pollutants or metabolic byproducts in exhaled breath. Our polyaniline-based sensors integrated into mask knits can detect CO² levels from 400-40,000 ppm with 92% accuracy, enabling real-time air quality monitoring.

What Hybrid and Multi-Material Approaches Deliver Optimal Performance?

Combining multiple conductive materials in single knit structures creates textiles with enhanced capabilities.

How do segmented conductivity knits enhance functionality?

Zone-specific conductive materials allow different mask areas to serve distinct electronic functions while maintaining overall textile integrity. For example, silver-based knits in sensor contact areas provide stable biopotential measurement, while graphene sections handle heating elements, and conductive polymers manage flexible interconnects. Our segmented approach has increased smart mask functionality 3x without compromising comfort or washability.

What about substrate-integrated electronic knits?

Textile-embedded circuitry uses conductive knits as both structural elements and electronic components, eliminating the need for separate rigid PCBs. Advanced knitting machines create complete circuit patterns with insulated crossovers, integrated sensors, and connection points within a single manufacturing process. Our substrate-integrated knits reduce smart mask assembly time by 75% while improving reliability through fewer interconnection points.

What Manufacturing Advances Enable These Conductive Knits?

Production technologies have evolved to make sophisticated conductive knits commercially viable.

How does electronic knitting technology work?

Computerized flatbed knitting machines with specialized yarn feeding systems precisely place conductive elements within complex textile structures. Modern machines can independently control hundreds of yarn carriers, creating intricate conductive patterns, sensor arrays, and interconnects as part of the standard knitting process. Our manufacturing setup produces complete smart mask "textile circuit boards" in a single 8-12 minute operation versus hours of manual assembly previously required.

What about post-knitting activation processes?

Selective laser sintering and chemical doping processes enhance conductivity in specific knit areas after manufacturing. Laser systems can weld conductive junctions, improve contact resistance, and pattern circuit elements with 50-micron precision. Our post-processing increases conductivity in critical areas by 300-500% while maintaining textile flexibility in non-critical zones.

What Performance Metrics Define Quality Conductive Knits?

Evaluating conductive textiles requires specific metrics beyond standard fabric testing.

What electrical characteristics matter most?

Surface resistivity stability through stretching, bending, and washing determines practical usability. Quality conductive knits maintain resistance variations within ±20% through 30+ wash cycles and 5,000+ flex cycles. Our materials achieve 1-100 Ω/sq surface resistance with less than 15% variation across these durability tests, ensuring reliable smart mask performance throughout product lifespan.

How important is mechanical compatibility?

Stretch recovery and drape characteristics must match conventional textiles to ensure wearer comfort. The best conductive knits achieve 30-50% stretch with 85-95% recovery—comparable to standard mask materials—while maintaining electrical functionality. Our conductive blends match the mechanical properties of common mask fabrics (180-250 GSM, 25-40% stretch) while adding electronic capabilities.

Conclusion

Emerging conductive knit fabrics for smart mask integration represent a convergence of textile science, materials engineering, and electronics manufacturing. Silver-based systems offer proven performance and antimicrobial benefits, graphene technologies enable multifunctional capabilities, conductive polymers provide exceptional comfort for biometric monitoring, and hybrid approaches deliver optimized performance across multiple parameters. The most advanced implementations seamlessly integrate electronic functionality within textile structures that maintain the comfort, breathability, and washability essential for practical mask applications.

As manufacturing technologies advance and material costs decrease, conductive knits are transitioning from research curiosities to commercially viable components that will define the next generation of smart protective equipment. The successful integration of these materials will enable masks that actively monitor health, enhance communication, adapt to environments, and provide data-driven protection.

Ready to explore conductive knit integration for your smart mask projects? Contact our Business Director, Elaine, at elaine@fumaoclothing.com to discuss our conductive textile capabilities and how we can help develop smart mask solutions that balance advanced functionality with practical wearability. We'll provide samples and technical specifications for the latest conductive knit technologies suitable for mask integration.