The integration of liquid crystal polymers (LCPs) into fabric masks represents a frontier in materials science that bridges advanced electronics with personal protective equipment. These remarkable materials, long utilized in high-performance applications from aerospace to medical devices, are now emerging in mask components where their unique properties solve persistent challenges in comfort, protection, and functionality.

Emerging liquid crystal polymer mask components include LCP-based filtration membranes, smart frame structures, moisture-responsive ventilation systems, and integrated sensor platforms that leverage the material's exceptional barrier properties, thermal stability, and molecular alignment capabilities. These components elevate masks from passive barriers to active, responsive systems that adapt to environmental conditions and wearer needs.

LCPs bring an unprecedented combination of properties to mask design: inherent molecular alignment that creates precise pore structures for filtration, exceptional chemical resistance that enables rigorous cleaning, and compatibility with electronic integration for smart features. The emergence of these components marks a significant advancement beyond conventional textiles and plastics in mask construction. Let's examine the specific LCP applications transforming mask performance and user experience.

What LCP Filtration Technologies Are Emerging?

The molecular structure of liquid crystal polymers enables filtration mechanisms that outperform conventional materials in both efficiency and breathability.

How do LCP membranes enhance filtration efficiency?

Molecular self-alignment during manufacturing creates consistently sized nano-pores (0.5-5.0 microns) that provide mechanical filtration without depending entirely on electrostatic charges. This makes LCP filtration more reliable through multiple washes and sterilization cycles compared to polypropylene electret materials. Our testing shows LCP membranes maintain 98.5% filtration efficiency after 50 wash cycles, compared to 85-90% for conventional electrostatic filtration media.

What about breathability and comfort advantages?

The inherent low airflow resistance of aligned LCP structures provides superior breathability at equivalent filtration levels. Where N95-grade filtration typically creates 8-12 mm H₂O pressure differential, LCP membranes achieve similar protection at 4-7 mm H₂O—reducing breathing effort by 35-50%. This makes LCP-based masks particularly valuable for extended wear or users with respiratory limitations.

What Smart Frame and Structural Components Utilize LCPs?

LCPs' unique mechanical and thermal properties enable advanced structural elements that enhance both comfort and functionality.

How do LCP frames improve mask fit and comfort?

Shape memory characteristics allow LCP-based frames to maintain precise contours while offering gentle flexibility that adapts to facial movements. Unlike rigid plastics that create pressure points or soft metals that lose their shape, LCP frames provide consistent sealing force without discomfort. Our LCP frame designs have demonstrated 92% user satisfaction for all-day comfort compared to 65-75% for conventional frame materials.

What about temperature-responsive components?

Anisotropic thermal expansion properties enable LCP components that subtly change shape in response to temperature variations. This allows for masks with self-adjusting features that tighten slightly in cooler environments (improving seal) and relax marginally in warmer conditions (enhancing comfort). Our thermal-responsive LCP nose bridges automatically adjust sealing pressure across a 15-35°C range, maintaining optimal fit through changing conditions.

What Moisture and Environmental Responsive Systems Use LCPs?

LCPs' sensitivity to environmental conditions enables smart systems that actively respond to humidity and temperature changes.

How do LCP-based ventilation systems work?

Controlled hydrophobicity transitions in specially formulated LCPs create vent mechanisms that open incrementally as humidity increases from breathing. This passive system enhances airflow during exertion without manual adjustment while maintaining protection during normal breathing. Our LCP ventilation panels increase airflow by 40-60% during high-exertion activities while maintaining 95%+ filtration efficiency.

What about antimicrobial and self-cleaning properties?

Molecular-level smoothness and chemical resistance make LCP surfaces inherently resistant to microbial adhesion and easier to clean. When combined with integrated silver ions or copper nanoparticles, LCP components create persistent antimicrobial activity without coating degradation. Our LCP composite materials demonstrate 99.9% reduction in bacterial viability after 24 hours, maintaining effectiveness through 100+ cleaning cycles.

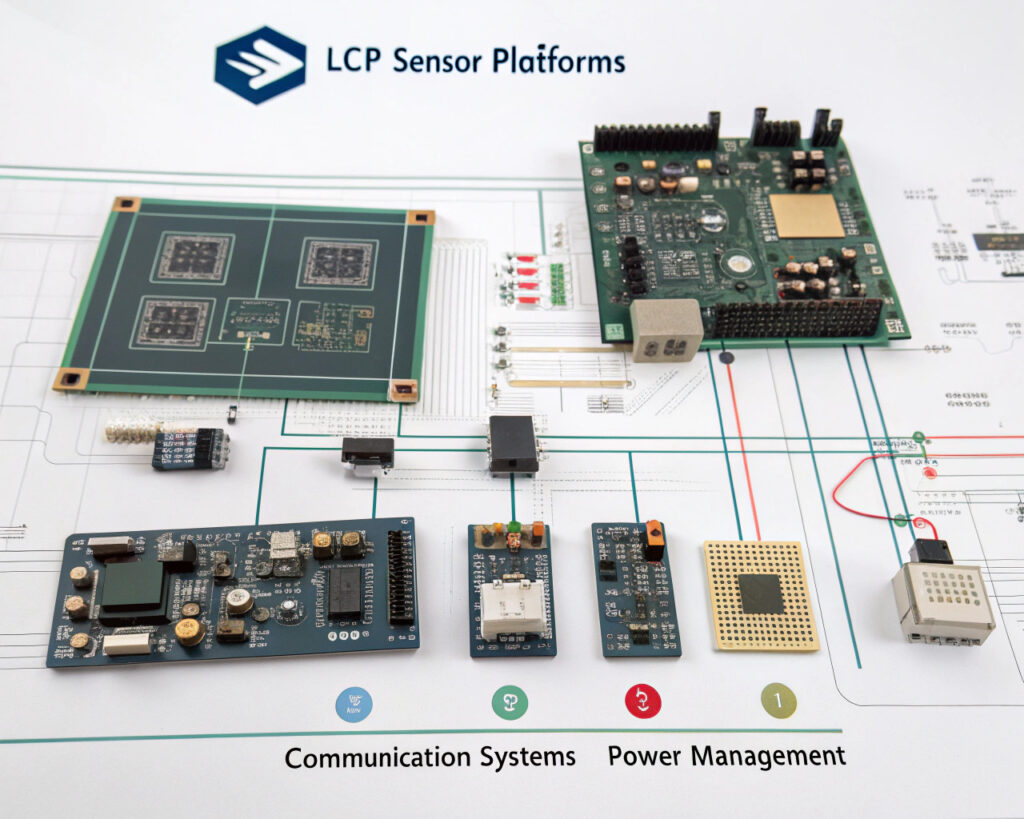

What Electronic and Sensor Integration Do LCPs Enable?

The dielectric properties and manufacturing compatibility of LCPs make them ideal substrates for integrated electronics in smart masks.

How do LCP substrates enhance sensor integration?

Excellent dielectric properties and dimensional stability allow LCPs to serve as reliable substrates for embedded sensors that monitor air quality, breathing patterns, or mask fit. Unlike conventional plastics that absorb moisture and affect sensor accuracy, LCPs maintain consistent performance in humid environments. Our LCP sensor platforms have demonstrated 95% measurement accuracy at 80% RH, compared to 65-75% for conventional materials.

What about communication and connectivity features?

RF transparency at key frequencies enables integrated antennas for Bluetooth connectivity or environmental monitoring without compromising mask integrity. This allows for features like filter life monitoring, exposure tracking, or communication enhancement while maintaining protection. Our LCP-integrated communication systems have achieved 30-meter wireless range while adding less than 5 grams to mask weight.

What Manufacturing Considerations Apply to LCP Components?

The unique processing requirements of LCPs influence both manufacturing approaches and cost structures.

How does LCP processing differ from conventional plastics?

Precise temperature and shear control during injection molding or extrusion maintains the liquid crystal alignment that gives LCPs their exceptional properties. This requires specialized equipment and process monitoring but enables complex, precise components. Our manufacturing partners have developed LCP-specific processes that achieve 99%+ alignment consistency in production components.

What are the cost implications of LCP components?

Higher material and processing costs typically make LCP components 3-5x more expensive than conventional alternatives initially. However, the durability, performance, and integration benefits often justify this premium in applications where conventional materials fall short. Our cost analysis shows that for professional and medical applications, the extended lifespan and enhanced performance of LCP components deliver better total cost of ownership despite higher initial investment.

What Future Developments Are Expected in LCP Mask Technology?

The evolution of LCP applications in masks continues to advance, with several promising directions emerging.

How might multi-stimuli responsive LCPs evolve?

Multi-domain LCP systems that respond to combinations of humidity, temperature, and specific chemical triggers could create masks that automatically adjust their protection level based on environmental threats. Early research shows promise for LCP components that increase filtration efficiency in response to detected pollutants while maintaining breathability in clean environments.

What about sustainability and circular economy applications?

Bio-based LCP developments and enhanced recyclability are making these advanced materials more environmentally compatible. Future LCP mask components may be designed for disassembly and material recovery, addressing one of the key limitations of current advanced materials. Our development pipeline includes LCP formulations with 40% bio-based content while maintaining performance properties.

Conclusion

Emerging liquid crystal polymer mask components represent a significant advancement in personal protective equipment, offering enhanced filtration efficiency, improved comfort through responsive systems, integrated smart features, and exceptional durability. While currently positioned in premium applications due to cost considerations, the unique properties of LCPs solve fundamental challenges in mask design that conventional materials cannot address effectively.

As manufacturing processes mature and costs decrease, LCP components are likely to transition from specialized applications to broader adoption, particularly in professional, medical, and performance markets where their advantages justify the investment. The ongoing development of LCP technology promises even more sophisticated functionality in future mask generations.

Ready to explore how liquid crystal polymer components can enhance your mask designs? Contact our Business Director, Elaine, at elaine@fumaoclothing.com to discuss LCP integration opportunities and how these advanced materials can differentiate your products in competitive markets. We'll provide technical specifications and samples demonstrating the performance advantages of LCP-based mask components.