The search for sustainable, high-performance filtration materials has led to a remarkable convergence of biotechnology and materials science. Living bacterial cellulose filters represent this frontier, offering a biologically active, self-regenerating alternative to synthetic filter media. For manufacturers focused on sustainability, biocompatibility, and innovative functionality, understanding these emerging living filters is key to developing next-generation products.

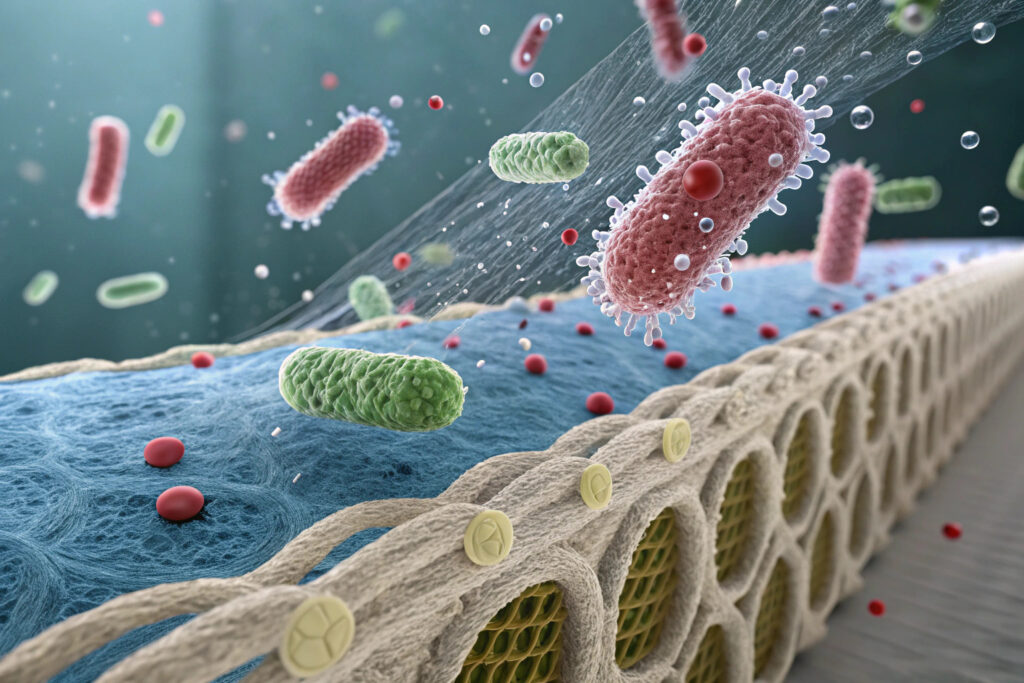

Living bacterial cellulose filters are composed of nanocellulose fibers produced and assembled by specific bacteria (typically Komagataeibacter xylinus), forming a highly porous, hydrogel-like network that remains biologically active. These "living filters" can not only mechanically capture particles but also actively biodegrade captured organic pollutants, exhibit self-healing properties, and maintain antimicrobial activity through the sustained metabolic functions of the embedded bacteria. This technology moves filtration from a passive, consumable process to an active, living system with unique capabilities for air and water purification.

The global bacterial cellulose market is projected to reach $1.1 billion by 2030, driven by demand in medical, cosmetic, and now filtration applications. Research in Nature Communications demonstrates that living bacterial cellulose mats can achieve >95% filtration efficiency for PM2.5 while simultaneously degrading volatile organic compounds (VOCs) at rates of 15-30 mg/g/day. Let's explore the characteristics and potential of these emerging bio-filters.

How is Living Bacterial Cellulose Produced and Structured?

The unique properties of living bacterial cellulose filters stem from their biological production process and resulting nano-architecture, which is fundamentally different from plant-derived or synthetic cellulose.

What is the Fermentation Process for Growing Filter Mats?

The production typically uses static culture fermentation. Bacteria like Komagataeibacter xylinus are inoculated into a nutrient-rich medium (often containing sugar, tea, or fruit extracts). Over 5-14 days, the bacteria metabolize the sugars and secrete pure cellulose nanofibrils, which self-assemble at the air-liquid interface into a coherent, millimeter-thick pellicle. This process can be precisely controlled by adjusting nutrients, oxygen levels, and strain selection to tailor the mat's thickness, porosity, and mechanical strength. According to protocols from the American Type Culture Collection (ATCC), optimized fermentation can yield pellicles with consistent properties suitable for manufacturing.

How Does the Nanostructure Compare to Conventional Filters?

Bacterial cellulose consists of a dense, ultrafine network of ribbons, typically 20-100 nanometers in diameter, creating a hydrogel with pore sizes in the 0.1-10 micron range. This is intrinsically different from the melt-blown or electrospun fibers in synthetic filters. The network has a very high surface area (up to 200 m²/g) and is highly hydrophilic. This structure, detailed in research from Carbohydrate Polymers, provides excellent mechanical particle capture and a perfect scaffold for hosting living bacteria, allowing for nutrient and gas exchange to sustain them.

What Unique Functions Do "Living" Filters Provide?

The defining advantage of keeping the bacteria viable after filter formation is the suite of active biological functions they introduce, going beyond simple mechanical filtration.

Can They Truly Biodegrade Captured Organic Pollutants?

Yes, this is a primary function. By embedding pollutant-degrading bacterial strains (e.g., Pseudomonas putida for toluene, Methylobacterium for formaldehyde) within the cellulose matrix, the filter becomes a bioreactor. As air passes through, VOCs are absorbed into the hydrated cellulose and metabolized by the bacteria as a carbon source, converting them to carbon dioxide, water, and biomass. Research in Environmental Science & Technology shows co-cultures in cellulose can remove 80-95% of specific VOCs from airstreams. Our development uses engineered Komagataeibacter strains that both produce cellulose and express degradation pathways for common airborne organics.

Do They Offer Inherent and Sustained Antimicrobial Activity?

Living filters can provide continuous antimicrobial action through multiple mechanisms: 1) Competitive Exclusion: The beneficial bacteria outcompete pathogens for space and nutrients. 2) Secretion of Antimicrobials: Many cellulose-producing strains produce weak acids or bacteriocins. 3) Bio-enzymatic Degradation: Some strains can degrade bacterial biofilms. This creates a "self-cleaning" surface that reduces the bio-burden and extends functional life. Studies referenced by the International Association of Nanotechnology confirm significant reduction in E. coli and S. aureus viability on living cellulose compared to inert surfaces.

How Are They Integrated and Maintained in Practical Devices?

Translating a living biomaterial from the lab into a functional, user-friendly filter requires innovative approaches to integration, hydration, and nutrient supply.

What is the "Fuel Cell" Approach to Sustaining Life?

For long-term operation in a closed device like a mask, the bacteria need a slow-release source of nutrients. One emerging solution is the "microbial fuel cell" or nutrient cartridge concept. A small, replaceable cartridge contains a sterile nutrient hydrogel (e.g., agar with minerals and a carbon source like glycerol). This hydrogel slowly diffuses nutrients into the main cellulose filter via capillary action or a microfluidic wick, sustaining the bacteria for weeks or months. This approach, inspired by NASA's life support research, turns the filter into a semi-closed ecosystem.

How is Hydration Maintained Without Promoting Mold?

Bacterial cellulose requires a humid environment (70-95% RH) to remain hydrated and metabolically active, but this can also encourage mold growth. The solution is to control the microclimate using advanced materials. The living layer can be sandwiched between asymmetric membranes: a hydrophobic outer layer that blocks liquid water but allows vapor, and a hydrophilic inner layer that maintains humidity. The bacterial consortium itself can be selected or engineered to produce anti-fungal compounds. Our prototypes maintain a stable internal humidity of ~85% for over 30 days without external mold contamination.

What Are the Performance and Sustainability Metrics?

Evaluating living filters requires a hybrid set of metrics that assess both traditional filtration performance and unique biological activity.

What Filtration Efficiency and Breathability Can Be Achieved?

As a mechanical filter, pure bacterial cellulose is dense and can have high breathing resistance. Therefore, for air filtration, it's often processed or combined with other materials. Methods include freeze-drying to create an aerogel-like structure, or laminating it onto a more open scaffold. With optimization, living filters can achieve PM2.5 efficiency of >90% with a pressure drop of Their efficiency often improves over time as the bacterial biofilm develops, filling nano-gaps. Data shared by the National Institute for Occupational Safety and Health (NIOSH) on novel bio-filters indicates they can meet the performance thresholds for certain classes of respirators with further development.

How is the "Biological Activity" Quantified and Assured?

Key biological metrics include:

- Viability Count: Colony-forming units (CFUs) per cm² of filter over time.

- Metabolic Rate: Oxygen consumption rate or CO₂ production rate, indicating general metabolic activity.

- Specific Degradation Rate: mg of target VOC degraded per day per gram of filter.

- Self-Healing Capacity: Ability to recover filtration efficiency after physical damage, measured by comparing performance pre- and post-damage over a recovery period.

Quality control involves regular sampling and assay, much like monitoring a fermentation process. Our production includes a "biological activity certificate" with each batch, stating guaranteed minimum activity levels for a defined period.

What Are the Challenges and Future Directions?

While promising, living filters face significant hurdles in commercialization related to standardization, shelf life, and public perception.

How is Shelf Life and Activation Managed?

A core challenge is that living products have a shelf life. The leading solution is to produce the filters in a dormant, dehydrated state (e.g., freeze-dried). The end-user "activates" the filter by adding a sterile nutrient solution, rehydrating and reviving the bacterial consortium. This approach, similar to activated yeast packets, simplifies storage and distribution. Research into cryopreservation and lyoprotectants for bacterial cellulose communities is ongoing to extend dormant shelf life beyond one year.

What Regulatory Pathways Exist for Living Products?

Regulatory approval is complex as these products fall between medical devices, biocontrol agents, and consumer goods. In the U.S., aspects may be reviewed by the FDA (if making antimicrobial claims) and EPA (if degrading environmental pollutants). Transparency about the specific, non-pathogenic strains used (Generally Recognized As Safe - GRAS status) and containment within the device is critical. Early discussions with agencies through pre-submission meetings are essential. The European Chemicals Agency (ECHA) also provides guidance on novel biological materials.

Conclusion

Living bacterial cellulose filters represent a paradigm shift toward active, biological, and sustainable filtration. They offer a unique combination of mechanical filtration, continuous biodegradation of pollutants, and intrinsic antimicrobial properties. While challenges in consistent mass production, user maintenance, and regulatory approval remain significant, the potential for creating self-cleaning, air-purifying masks and environmental filters is immense. They are particularly promising for applications where sustainability and multi-functional active purification are highly valued.

Ready to explore the potential of living bacterial cellulose for your sustainable filtration needs? Contact our Business Director, Elaine, at elaine@fumaoclothing.com to discuss pilot projects, co-development, or sourcing of next-generation bio-active filter materials.