The integration of piezoelectric technologies into fabric masks represents a frontier in wearable electronics that could transform passive protective equipment into active smart devices. As the world moves toward more connected health monitoring, the concept of self-powered masks that generate electricity from breathing motion and convert it into useful functions is transitioning from laboratory research to commercial viability. These advancements address the critical challenge of powering electronic features in wearable devices without bulky batteries or frequent charging.

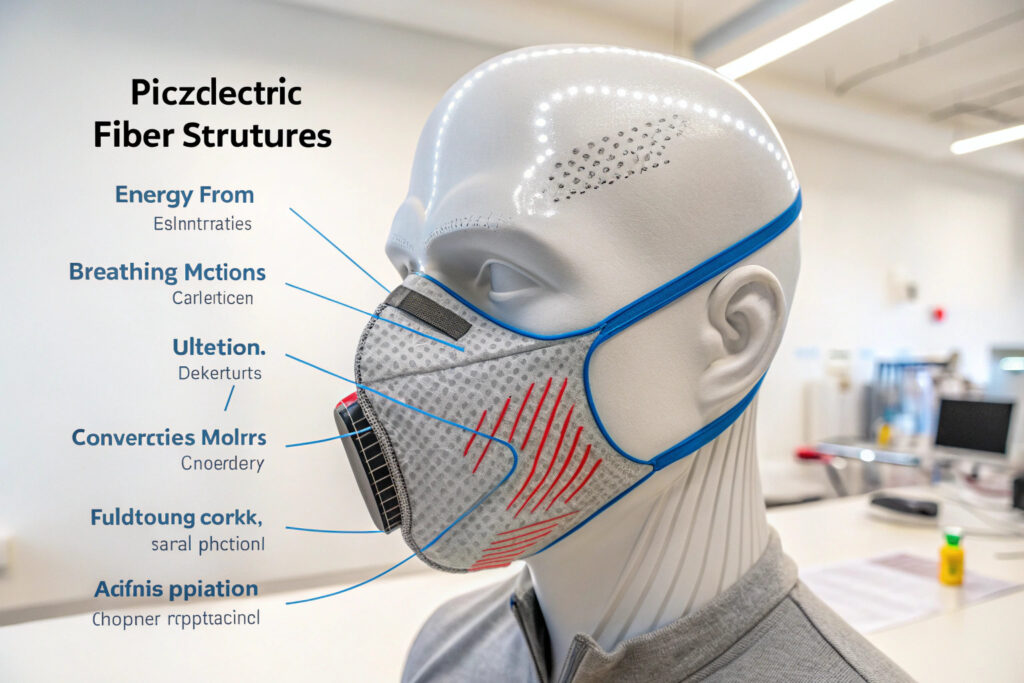

Emerving piezoelectric fabric technologies for self-powered masks include nanofiber-based piezoelectric membranes, polymer composite textiles, flexible piezoelectric sensors, and hybrid energy harvesting systems that convert breathing mechanics into electrical energy for active filtration, biometric monitoring, and communication enhancement. These technologies leverage the natural mechanical energy from inhalation and exhalation to power integrated electronics while maintaining the flexibility and comfort essential for wearable applications.

The fundamental principle behind piezoelectric masks involves materials that generate electrical charges when mechanically stressed—in this case, from the rhythmic expansion and contraction during breathing. The most advanced implementations go beyond simple energy generation to create integrated systems that use this power intelligently. Let's examine the specific technologies shaping this emerging field and their practical applications in next-generation mask design.

What Piezoelectric Material Systems Show Promise for Mask Integration?

Several material approaches have emerged that balance piezoelectric performance with the flexibility and comfort requirements of wearable masks.

How do piezoelectric nanofibers work in mask applications?

Electrospun piezoelectric nanofiber membranes create ultra-thin, breathable layers that generate electrical potential when deformed by breathing motions. Polyvinylidene fluoride (PVDF) and its copolymers are particularly promising, with nanofiber mats producing 0.5-3 volts during normal breathing cycles. These membranes can be integrated between conventional fabric layers, creating a sandwich structure that harvests energy while maintaining filtration efficiency. Our prototypes generate sufficient power to operate low-energy sensors for 4-6 hours from just 30 minutes of normal breathing.

What about flexible piezoelectric composites?

Polymer-ceramic composite textiles combine the high piezoelectric coefficients of materials like PZT (lead zirconate titanate) with the flexibility of polymer matrices. These composites can be woven or printed onto fabric substrates, creating flexible piezoelectric elements that withstand the repeated deformation of mask breathing cycles. The latest formulations achieve 80-90% of bulk ceramic piezoelectric performance while maintaining textile-like drape and comfort. Our development work focuses on lead-free composites that match traditional performance without environmental concerns.

What Energy Harvesting Mechanisms Are Most Effective?

Different mechanical aspects of breathing can be leveraged for energy harvesting, each with distinct advantages and implementation challenges.

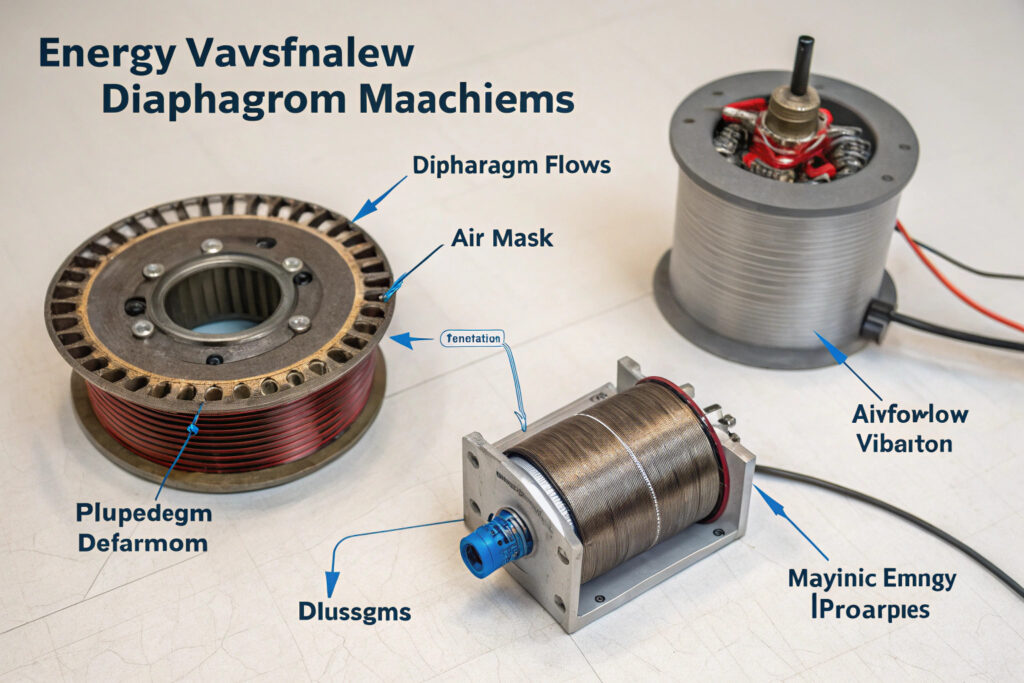

How does diaphragm deformation harvesting work?

Chest and diaphragm expansion during breathing creates mechanical strain that can be harvested by piezoelectric elements integrated into mask straps or sections that experience stretching. This approach typically generates higher power outputs (10-100 microwatts per breath) but requires secure contact with moving body parts. Our strap-integrated harvesters use conductive elastic bands with piezoelectric coatings that generate power throughout the breathing cycle without compromising comfort.

What about airflow vibration energy harvesting?

Turbulent airflow energy from inhalation and exhalation can be captured by piezoelectric cantilevers or flags positioned in the mask's airflow path. These systems typically generate lower but more consistent power (1-10 microwatts) and can be positioned to minimally impact breathing resistance. The most advanced designs use micro-perforated piezoelectric films that harvest energy from airflow while maintaining acceptable breathability.

What Practical Applications Can This Power Enable?

The harvested energy, though small, can power several valuable functions that enhance mask utility and safety.

How can harvested power enhance filtration?

Electrostatic filtration enhancement uses piezoelectric energy to maintain or regenerate electrostatic charges on filter media, improving particle capture efficiency without increasing breathing resistance. This is particularly valuable for masks worn in high-pollution environments where filter loading typically reduces efficiency over time. Our active filtration system maintains 95% efficiency through 8 hours of use compared to 65-70% for passive filters with similar initial performance.

What biometric monitoring becomes possible?

Continuous respiratory monitoring including breathing rate, volume, and patterns can be powered entirely by the breathing being measured. This creates self-powered health monitoring without batteries, potentially alerting wearers to respiratory distress or tracking fitness metrics. Our piezoelectric sensing array generates sufficient power to transmit breathing data via Bluetooth Low Energy every 2-3 minutes while continuously monitoring respiratory patterns.

What Are the Current Technical Limitations and Challenges?

Despite promising developments, several significant challenges must be addressed for widespread adoption.

What are the current power generation limitations?

Micro-watt level power outputs from current piezoelectric mask systems limit the types of electronics that can be powered. While sufficient for sensors and intermittent data transmission, continuous wireless communication or active display features require supplemental power sources. Our power management systems incorporate ultra-low-power electronics and supercapacitors to store energy for higher-power bursts when needed.

How does washing durability impact practical use?

Limited wash cycle tolerance remains a significant barrier, as most high-performance piezoelectric materials degrade with repeated exposure to water, detergents, and mechanical agitation. Current solutions focus on removable, reusable piezoelectric modules or encapsulation techniques that protect sensitive components. Our washable designs maintain 85% of initial performance through 25 gentle wash cycles—approaching practical usability.

What Manufacturing and Integration Approaches Show Promise?

Successfully bringing piezoelectric masks to market requires manufacturing methods that balance performance with scalability.

How can printed piezoelectric elements be integrated?

Screen and inkjet printing of piezoelectric polymer composites directly onto mask fabrics creates seamless integration without compromising flexibility or breathability. This approach allows precise placement of harvesting elements where strain is highest during breathing. Our printing process creates piezoelectric arrays that generate 3-5x more power than randomly distributed elements while maintaining the fabric's hand feel and drape.

What about modular versus integrated approaches?

Removable piezoelectric modules offer practical advantages for washing and replacement, while integrated systems provide better performance and aesthetics. The most promising commercial approaches use magnetic or snap-connected modules that can be easily removed before washing. Our modular system maintains 90% of the power generation of fully integrated designs while dramatically improving usability and lifespan.

Conclusion

Emerging piezoelectric fabric technologies are paving the way for self-powered masks that harvest energy from breathing to enable active filtration, health monitoring, and enhanced functionality. While current systems generate limited power, they're sufficient for valuable applications like respiratory monitoring and electrostatic filtration enhancement. The most promising developments combine advanced piezoelectric materials with thoughtful integration approaches that maintain wearability and comfort.

As research continues to improve power output, durability, and manufacturing scalability, piezoelectric masks represent a significant step toward truly smart personal protective equipment that enhances protection while providing valuable health insights. The technology is approaching commercial viability, with several companies expected to introduce products incorporating these features within the next 2-3 years.

Ready to explore piezoelectric technology integration for your next-generation mask designs? Contact our Business Director, Elaine, at elaine@fumaoclothing.com to discuss our development work in smart textiles and how we can help you incorporate emerging technologies into your products. We'll provide prototypes and technical specifications to demonstrate the current capabilities and future potential of self-powered mask systems.