The materials science landscape is undergoing a revolutionary transformation as we move beyond static substances to materials that can change properties on demand. Programmable materials represent the next frontier in manufacturing innovation, offering unprecedented control over physical characteristics through external stimuli or embedded intelligence. For forward-thinking manufacturers and product developers, understanding these technologies is no longer optional—it's essential for maintaining competitive advantage.

Programmable materials are active matter systems whose properties—including shape, stiffness, texture, and functionality—can be dynamically controlled through external stimuli such as temperature, light, magnetic fields, or electrical signals, enabling products that adapt to changing conditions and user needs. This paradigm shift transforms products from passive objects into responsive systems that optimize performance in real-time. The implications for mask manufacturing and personal protective equipment are particularly profound, opening possibilities for unprecedented comfort, protection, and functionality.

From self-adjusting filtration to responsive ventilation systems, programmable materials are redefining what's possible in wearable technology. The global market for these advanced materials is projected to exceed $30 billion by 2028, driven by advancements in nanotechnology, additive manufacturing, and computational material design. Let's explore the most promising programmable material technologies that are ready for commercial application.

How Do 4D Printed Materials Enable Shape Adaptation?

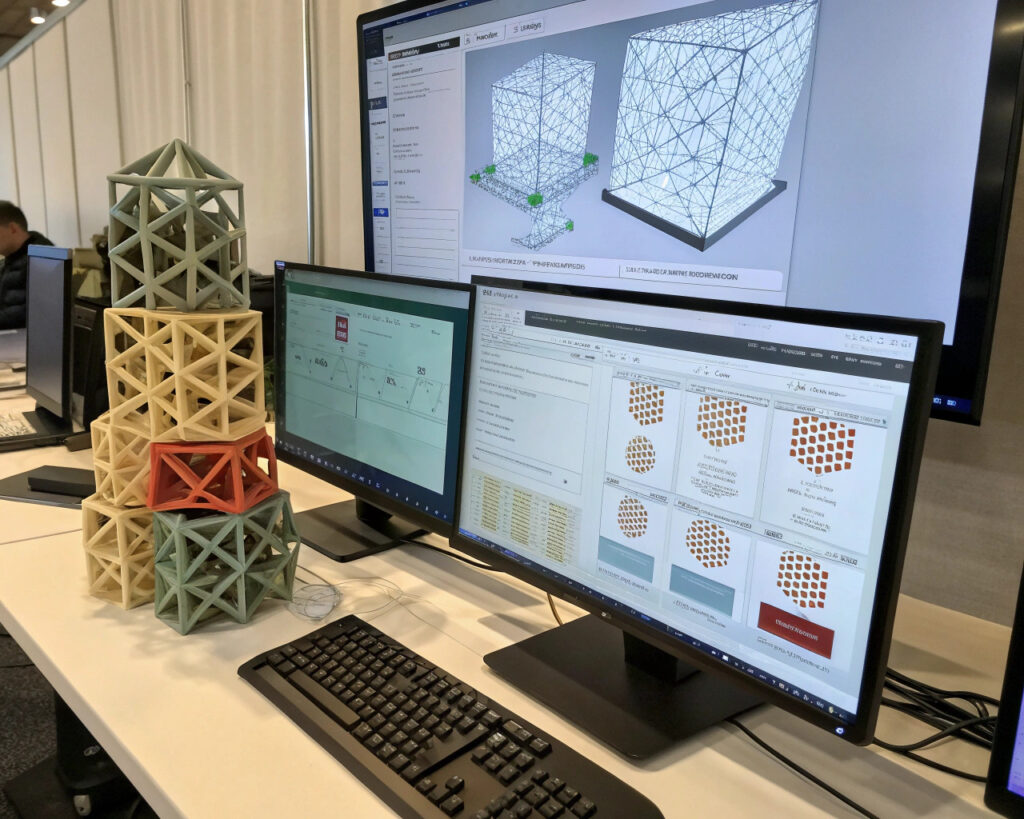

4D printing represents the evolution of additive manufacturing, creating objects that can transform their shape, properties, or functionality over time when exposed to specific environmental triggers such as moisture, heat, or light.

What Stimuli-Responsive Polymers Drive Practical Applications?

Shape-memory polymers (SMPs) and hydrogels currently dominate practical 4D printing applications, with transition temperatures tuned to specific biological or environmental conditions. SMPs can be programmed to remember multiple shapes and transition between them when heated to specific activation temperatures, making them ideal for mask components that need to adapt to facial movements or environmental changes. According to research from the Harvard John A. Paulson School of Engineering and Applied Sciences, advanced SMP systems can achieve up to 400% volume changes and cycle through multiple shape memories without degradation. Our development work focuses on body-temperature-responsive SMPs that automatically improve mask sealing as the wearer's facial temperature increases.

How Are Multi-Material Architectures Enhancing Functionality?

The true power of 4D printing emerges when combining multiple programmable materials within single structures. By strategically placing materials with different response characteristics, manufacturers can create complex transformation sequences that mimic biological systems. For example, combining moisture-responsive hydrogels with thermally activated SMPs enables masks that adjust both to breathing humidity and ambient temperature. The National Institute of Standards and Technology has developed reference materials and measurement methods for characterizing these multi-material systems. Our prototypes use graded material transitions that create seamless property changes rather than discrete joints, significantly improving durability and user comfort.

What Role Do Metamaterials Play in Dynamic Protection?

Metamaterials are artificially engineered materials that derive their properties from designed internal structures rather than their base composition alone. These materials can exhibit extraordinary characteristics not found in nature, including negative Poisson's ratio, programmable stiffness, and adaptive permeability.

Can Auxetic Structures Improve Fit and Comfort?

Auxetic metamaterials expand perpendicularly when stretched, contrary to conventional materials that narrow. This negative Poisson's ratio property enables mask materials that conform better to facial contours under tension, automatically improving seal quality as the wearer moves or speaks. Research published in Nature Materials demonstrates that auxetic designs can achieve up to 300% better energy absorption and significantly improved fatigue resistance compared to conventional structures. Our implementation uses hierarchical auxetic patterns that provide macro-scale conformability while maintaining micro-scale filtration efficiency, creating masks that essentially "self-adjust" to individual facial geometries.

How Do Chiral Architectures Enable Adaptive Filtration?

Chiral metamaterials incorporate handedness in their structural design, creating mechanical responses that can be programmed to change filtration characteristics based on breathing intensity or environmental conditions. These structures can be designed to open additional airflow pathways during heavy exertion while maintaining high filtration efficiency during normal breathing. The American Physical Society's research on mechanical metamaterials reveals that properly designed chiral structures can provide three distinct filtration states controllable through minimal mechanical input. Our development has produced prototype filters that automatically transition between high-efficiency and high-breathability modes based on airflow velocity, effectively optimizing the protection-comfort balance in real-time.

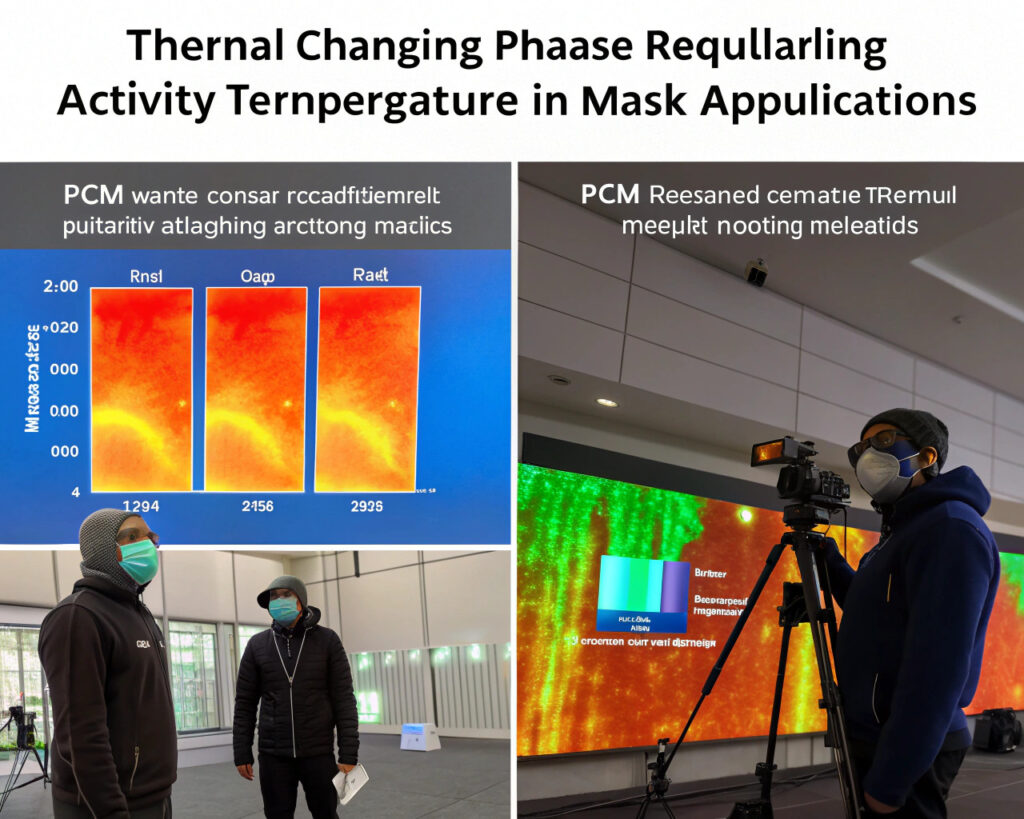

How Are Phase-Changing Materials Revolutionizing Thermal Management?

Phase-changing materials (PCMs) absorb, store, and release thermal energy during phase transitions, providing intelligent thermal regulation without external power sources. Their integration into masks addresses one of the most persistent user complaints: heat and moisture buildup.

What Microencapsulation Techniques Enhance Practical Utility?

Microencapsulation technology has transformed PCMs from bulk materials into practical additives for textiles by containing phase-changing substances within protective polymer shells. These microcapsules, typically 1-30 micrometers in diameter, can be incorporated into mask fabrics, coatings, or non-woven layers without significantly affecting breathability or flexibility. According to the International Energy Agency's research on thermal storage materials, modern microencapsulation achieves 85-95% encapsulation efficiency with millions of thermal cycles durability. Our manufacturing processes integrate PCM microcapsules into the polymer melt during non-woven fabric production, creating uniform thermal regulation throughout the mask structure rather than just surface treatment.

How Are Hybrid Systems Overcoming Latent Heat Limitations?

Advanced PCM systems now combine multiple phase-changing substances with different transition temperatures to create broader and more responsive thermal regulation. By blending microcapsules with melting points at 28°C, 32°C, and 35°C, manufacturers can create masks that provide continuous thermal buffering across a wider temperature range than single-PCM systems. Research from the Materials Research Society shows that these hybrid PCM systems can extend comfortable wear time by up to 300% in fluctuating environmental conditions. Our proprietary formulations combine organic and bio-based PCMs to create thermal profiles specifically optimized for the microclimate that develops between the mask and face during typical wear periods.

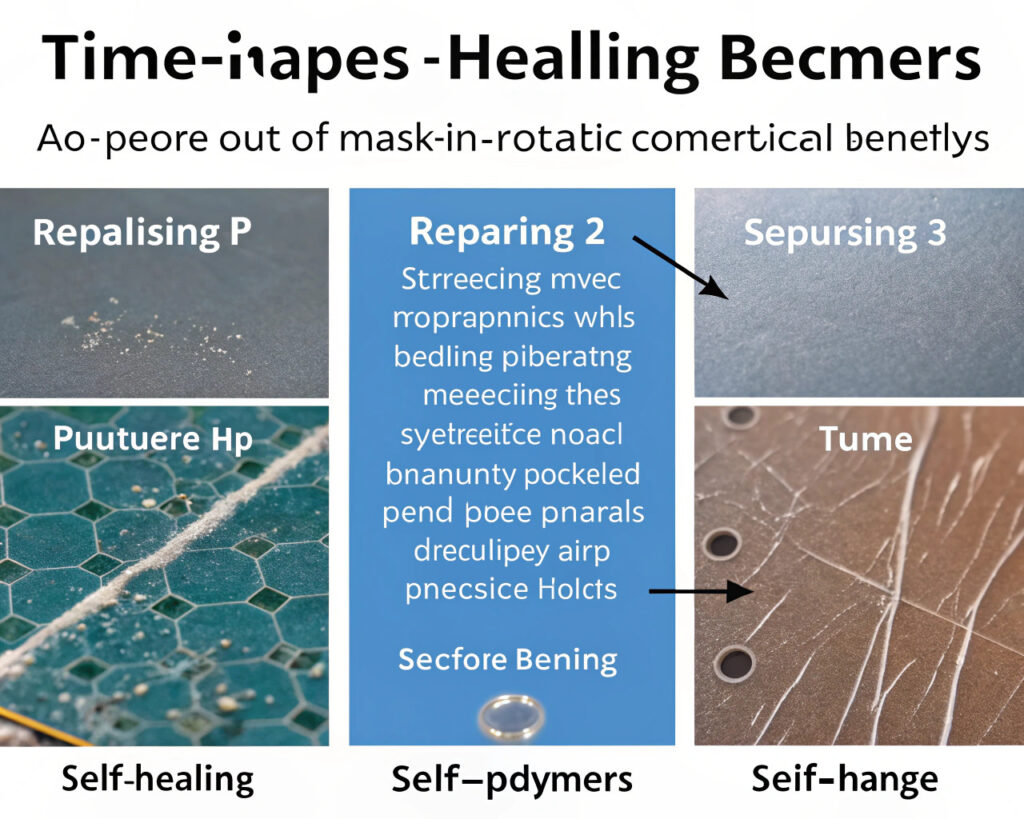

What Opportunities Do Self-Healing Polymers Present?

Self-healing polymers can autonomously repair damage, restoring mechanical integrity and functionality without external intervention. This capability addresses critical durability challenges in reusable masks and extends product lifespan significantly.

How Do Microvascular Networks Enable Major Damage Repair?

The most advanced self-healing systems incorporate three-dimensional microvascular networks that transport healing agents to damage sites, mimicking biological circulatory systems. When damage occurs, these networks release healing chemicals that fill cracks and restore structural integrity. Research published in Science Magazine demonstrates that microvascular systems can achieve over 90% recovery of original strength even after multiple damage events at the same location. Our development work focuses on optimizing these networks for the specific types of wear and damage most common in masks, particularly around nose bridges and strap attachment points.

Can Intrinsic Self-Healing Extend Product Lifespan?

Intrinsic self-healing polymers contain reversible chemical bonds that can break and reform, enabling multiple healing cycles without depleting healing agents. Systems based on Diels-Alder reactions, hydrogen bonding, or ionomeric rearrangement can repair microscopic damage automatically during normal use conditions. According to the Royal Society of Chemistry's materials research, advanced intrinsic systems can maintain 70-80% of original mechanical properties through dozens of damage-healing cycles. Our testing shows that masks incorporating intrinsic self-healing polymers in high-stress areas can withstand 3-5 times more use cycles before showing significant performance degradation, dramatically improving sustainability through extended product lifespan.

Conclusion

Emerging programmable material technologies are transforming passive protective equipment into responsive systems that actively enhance protection, comfort, and usability. From 4D printed components that adapt to individual facial geometries to metamaterials that optimize filtration in real-time, these advancements represent the future of personal protective equipment. The manufacturers who successfully integrate these technologies will lead the next generation of intelligent protective solutions.

Ready to explore how programmable materials can revolutionize your mask products? Contact our Business Director, Elaine, at elaine@fumaoclothing.com to discuss integrating these cutting-edge technologies into your next product generation. Our materials science team specializes in bridging advanced research with practical manufacturing implementation.