Conventional air filtration relies on passive physical barriers or chemical reactions that have inherent limitations—fixed pore sizes, saturation points, and the inability to selectively neutralize specific biological threats. The emerging field of synthetic biology is revolutionizing this paradigm by engineering living cells and biomolecular systems to actively sense, capture, and degrade airborne pathogens and pollutants. For manufacturers at the forefront of protective equipment, understanding these bio-hybrid systems is key to developing the next generation of intelligent, self-regenerating filtration.

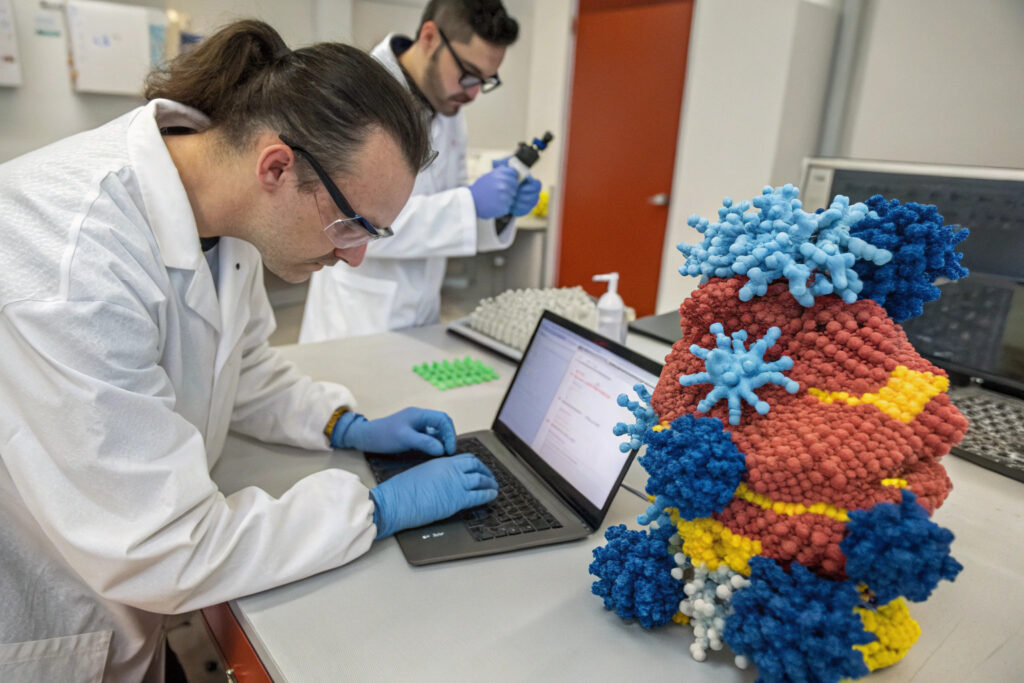

Emerging synthetic biology air filtration systems integrate engineered biological components—such as designer proteins, reprogrammed bacterial consortia, or cell-free metabolic pathways—into filter matrices to create 'living filters' that actively neutralize threats, self-repair, and adapt to environmental changes, moving beyond passive capture to active biological processing of airborne contaminants. This approach leverages billions of years of evolutionary refinement in biological recognition and catalysis, redirecting it for human protection in a controlled, safe, and scalable manner.

The synthetic biology market is projected to exceed $35 billion by 2027, with significant investment flowing into bio-remediation and biomedical applications. Translating this into air filtration represents a frontier where biological precision meets materials engineering. Unlike a HEPA filter that merely traps viruses, a synthetic biology filter could identify, enzymatically dismantle, and use their components as fuel. Let's examine the most promising architectures moving from lab to commercial scale.

What Are Engineered Protein-Based Capture and Neutralization Systems?

The most immediate applications involve designer proteins that can be produced at scale and integrated into fibrous matrices without living cells, offering a blend of high activity and simplified regulatory approval.

How Do Hyper-Stable Binding Proteins Target Specific Pathogens?

Researchers are using computational protein design (e.g., with tools like Rosetta) to create hyper-stable mini-proteins that bind with ultra-high affinity to conserved regions of viral surface proteins, such as the SARS-CoV-2 spike protein or influenza hemagglutinin. These designed proteins, often based on scaffolds like affibodies or monobodies, are orders of magnitude smaller and more stable than conventional antibodies. Once bound, they can irreversibly neutralize the pathogen by blocking cell entry or triggering conformational changes. According to research published in Science, such proteins retain function after being spray-dried onto surfaces and can withstand moderate temperature fluctuations. Sourcing involves partnering with biotech firms specializing in computational protein design and GMP bio-production.

What is the Role of Engineered Lytic Enzymes?

Beyond capture, engineered lytic enzymes provide active destruction. Bacteriophage-derived lysins, engineered to have broad-spectrum activity, can be designed to puncture the membranes of specific categories of bacteria (e.g., Gram-positive) upon contact. For viruses, engineered viral lytic enzymes or programmable DNA/RNA nucleases can be designed to degrade the genetic material of target pathogens upon capture. These enzymes are immobilized on filter fibers using enzyme-friendly covalent linkage strategies. The key sourcing consideration is the activity half-life of the immobilized enzyme under flowing, dry air conditions. Suppliers should provide data on enzymatic activity retention over time and after exposure to environmental stressors.

How Are Living Bacterial Consortia Being Safely Contained in Filters?

More advanced systems employ communities of non-pathogenic, engineered bacteria that perform complex biochemical filtration tasks. The central challenge is absolute containment—ensuring bacteria stay within the filter while performing their function.

What Containment Strategies Enable Safe Use?

Double containment is the prevailing strategy. First, bacteria are engineered with multiple 'suicide switches' (e.g., based on the lack of a supplied essential nutrient outside the capsule). Second, they are physically encapsulated within semi-permeable polymer microcapsules or hydrogel beads that allow air and small pollutant molecules to diffuse in, but prevent bacterial cells from escaping. These bead-filled layers are then sandwiched between upstream pre-filters and downstream sterile absolute barriers (e.g., nanofiber layers). Frameworks from the NIH Guidelines for Recombinant DNA and the EPA's regulations on microbial products provide the containment design roadmap. Sourcing requires partners with rigorous biocontainment expertise and a quality control system to test containment integrity for every production batch.

What Metabolic Pathways Are Engineered for Pollutant Breakdown?

Bacteria can be reprogrammed to use airborne pollutants as their sole carbon or energy source. For example, the soil bacterium Pseudomonas putida has been engineered with metabolic pathways to break down toxic VOCs like benzene, toluene, and formaldehyde into harmless metabolites. Other strains are designed to capture and reduce heavy metal particles. The synthesis of these pathways is guided by databases like BioCyc and the Joint BioEnergy Institute's tools. When sourcing, evaluate the stability of the engineered genetic circuit over many bacterial generations within the capsule and the efficiency of pollutant removal under realistic, low-concentration, flowing air conditions.

What Are Cell-Free Synthetic Biology Systems?

Cell-free systems extract the molecular machinery of life—ribosomes, enzymes, cofactors—from cells and utilize them in vitro, offering the programmability of biology without the complications of living, replicating organisms.

How Do Freeze-Dried, Field-Deployable Circuits Work?

The breakthrough for filtration is the development of freeze-dried, shelf-stable cell-free reactions. These pellets contain all biomolecular components needed for transcription and translation (TX-TL) lyophilized onto a porous substrate. When rehydrated by ambient humidity, they can be programmed with synthetic DNA to perform functions like pathogen detection, signal amplification, and production of a therapeutic or degrading agent. Research from the Wyss Institute has demonstrated such systems can remain stable for over a year at room temperature. For masks, this could enable a filter that changes color upon detecting a specific virus, or that releases a burst of neutralizing enzymes only when triggered. Sourcing this technology involves engaging with pioneers in cell-free biomanufacturing.

What Sensing and Response Capabilities Are Possible?

Cell-free systems can be programmed with sophisticated genetic logic gates (AND, OR, NOT). This allows for highly specific detection: for instance, only activating a response if both a viral RNA signature and a marker of human inflammatory response (like a specific miRNA in exhaled breath condensate) are present, indicating an active infection. The response could be the production of a biodegradable bioluminescent signal for the wearer, or the localized release of an antiviral peptide. Sourcing requires defining the desired detection logic and the stability of the freeze-dried components under the variable humidity and temperature conditions inside a mask.

What Are the Manufacturing and Regulatory Pathways?

Scaling and gaining approval for bio-hybrid filters present unique challenges compared to traditional materials, requiring novel manufacturing approaches and early regulatory engagement.

How Are Biological Components Integrated at Scale?

Integration methods must preserve biological function. Spray-coating with biocompatible adhesives, inkjet printing of biological inks, and electrospinning of polymer-biology hybrid fibers are leading techniques. For cell-free systems, immersion coating followed by controlled lyophilization is key. The entire process requires strict control over temperature, pH, and sterility at specific stages. Manufacturing partners need expertise in both bioprocess engineering and non-woven textile production—a rare combination. Pilot production lines are now being established to demonstrate this convergence.

How to Navigate the Regulatory Landscape for Bio-Hybrid PPE?

Regulatory classification is complex. A filter with immobilized, non-replicating engineered proteins may be regulated as a medical device (e.g., FDA Class II, CE MDD). A product containing contained, living genetically modified microorganisms (GMOs) may fall under both medical device and GMO/biopesticide regulations (EPA, USDA). Early and frequent consultation with regulators is imperative. The pathway involves demonstrating: 1) Safety: No release of GMOs, no toxicity or allergenicity from biological components. 2) Efficacy: Consistent biocidal or filtration performance per relevant standards (e.g., ASTM F3502, NIOSH). 3) Manufacturing Quality: Consistent activity and purity batch-to-batch. Sourcing must include partners with a clear regulatory strategy and experience in submitting Biologics Master Files.

Conclusion

Synthetic biology air filtration systems represent a paradigm shift from inert materials to dynamic, biologically active protection. From engineered proteins and contained bacterial consortia to programmable cell-free circuits, these technologies offer the potential for filters that adapt, regenerate, and provide targeted defense. While challenges in manufacturing scalability, long-term stability, and regulatory approval remain significant, the trajectory is clear: the future of high-performance filtration will incorporate principles of biological design. Early engagement with innovators in this space is crucial for companies aiming to lead the next wave of personal protective equipment.

Ready to explore the frontier of synthetic biology for advanced air filtration in your products? Contact our Business Director, Elaine, at elaine@fumaoclothing.com. We are actively monitoring and partnering with pioneers in this field to bring biologically intelligent protection from the lab to practical, manufacturable mask solutions.