The convergence of additive manufacturing, smart materials, and sustainable design is giving rise to a revolutionary class of substances: 4D-printed biodegradable smart materials. Unlike conventional 3D printing that creates static objects, 4D printing produces structures that can transform their shape, properties, or functionality over time in response to environmental stimuli—and now, they're designed to safely biodegrade after their useful life. For mask manufacturers and wearable technology developers, these materials offer a pathway to creating adaptive, high-performance products with a radically reduced environmental footprint.

The latest 4D-printed biodegradable smart materials are composed of bio-based polymers and composites that are programmed during the printing process to undergo predictable shape-memory transformations, property changes, or even self-assembly when triggered by body heat, moisture, or specific pH levels, while ultimately breaking down into non-toxic components in industrial compost or marine environments. This technology enables masks that adapt their fit post-manufacturing, filters that change porosity based on humidity, or components that self-disassemble for easier recycling, all while aligning with the strictest circular economy principles.

The global market for 4D printing is projected to reach $537 million by 2030, with healthcare and wearable tech as primary drivers. The "fourth dimension" is time-responsive behavior, and when combined with certified biodegradability, it addresses two major industry pain points: static product limitations and plastic waste. These materials aren't just futuristic concepts; they are entering pilot production with defined degradation timelines and tunable transformation triggers. Let's explore the most advanced formulations and their practical applications.

What Bio-Based Polymers Form the Foundation?

The backbone of these materials is a new generation of polymers derived from renewable resources, engineered not just for printability but for programmable responsiveness and controlled degradation.

Why Are Shape-Memory PHAs Leading for Wearable Applications?

Polyhydroxyalkanoates (PHAs), produced by bacterial fermentation of plant sugars, are emerging as the premier shape-memory biodegradable polymer for 4D printing. Unlike PLA, which is brittle, certain PHAs like poly(3-hydroxybutyrate-co-3-hydroxyvalerate) – PHBV – exhibit excellent elasticity and a tunable glass transition temperature (Tg). By programming the print path and annealing the structure at a specific temperature (e.g., 60°C), a PHA-based mask component can be "set" to a temporary shape (flat for packaging) and then recover to its original, complex shape (a 3D contour) when warmed by the wearer's face (~35°C). Research in Advanced Science shows PHA-based 4D structures achieving over 98% shape recovery and fully biodegrading in soil within 6-24 months. Sourcing involves partnering with biopolymer specialists who can supply PHA compounds with consistent Tg for reliable 4D programming.

How Do Chitosan-Based Hydrogels Enable Moisture-Responsive Actuation?

Chitosan, derived from chitin in crustacean shells, forms pH-responsive and moisture-sensitive hydrogels ideal for 4D printing via direct ink writing (DIW). When printed in a specific pattern and crosslinked, chitosan hydrogels can swell or contract dramatically in response to humidity changes from breathing. For a mask, this could be used to create an intelligent seal that tightens in moist conditions (improving fit during exertion) or to design moisture-activated valves that open for better ventilation. According to studies in the Carbohydrate Polymers journal, 4D-printed chitosan structures can achieve over 300% volume change. The key sourcing parameter is the degree of deacetylation (DDA) of the chitosan, which controls its swelling ratio and biodegradation rate.

What Stimuli-Responsive Mechanisms Are Most Practical?

The "smart" behavior is dictated by the incorporated stimuli-responsive mechanisms. The latest advances focus on triggers that are naturally present in the use environment, like body heat, sweat, or the carbon dioxide in exhaled breath.

How is Body Heat Used as a Reliable Trigger?

Body heat is a consistent, low-energy trigger. The mechanism relies on shape-memory polymers (SMPs) with a Tg slightly above room temperature but below skin temperature (typically 30-40°C). During 4D printing, the material is deposited in a strained configuration. When later heated by the face, the polymer chains gain mobility and return to their "remembered," relaxed state, causing the part to fold, bend, or expand. Advanced formulations now use graded or multi-material printing to create parts that transform in a specific sequence. For instance, the nose bridge area of a mask might activate first (at 32°C) to secure the mask, followed by the cheek flaps (at 35°C) for a complete seal. This graded response requires precise control over the polymer chemistry and print parameters, offered by specialized 4D printing service bureaus.

Can CO2-Responsive Materials Create "Breathing" Filters?

Emerging research focuses on materials that respond to carbon dioxide, a major component of exhaled breath. Polymers containing CO2-responsive groups like amidines change their hydrophilicity when exposed to CO2 in the presence of moisture. In a 4D-printed filter matrix, this could cause the pores to temporarily widen during exhalation (high CO2) to reduce breathing resistance, and then tighten during inhalation (ambient air, low CO2) to maximize filtration. Papers in Nature Communications detail such gas-responsive gels. While still in early stages, sourcing this technology involves engaging with university spin-offs and chemical companies developing functional monomers for additive manufacturing.

What Ensures Predictable and Safe Biodegradation?

For true sustainability, the material must not only biodegrade but do so in a predictable timeframe and into harmless byproducts, without generating microplastics.

How Are Degradation Rates Programmed During Printing?

The degradation rate can be "programmed" through material composition and print architecture. By blending fast-degrading polymers (like thermoplastic starch) with slower-degrading ones (like PHA) in specific voxel patterns during multi-material 4D printing, manufacturers can create parts with differential degradation. For example, the structural frame of a mask might degrade in 12 months, while a moisture-responsive seal degrades in 3 months. Furthermore, printing highly porous infill structures increases surface area for microbial attack, accelerating breakdown. Suppliers should provide degradation data according to international standards such as ISO 14855 (compost) or ASTM D6691 (marine).

What Certifications Verify Non-Toxicity of Byproducts?

Biodegradation is meaningless if it leaves toxic residues. Sourcing must focus on materials that have obtained recognized ecotoxicity certifications. The most rigorous is the OK compost INDUSTRIAL certification (by TÜV Austria), which verifies complete biodegradation in an industrial composting plant within 6 months and that the resulting compost supports plant growth. For marine environments, the OK biodegradable MARINE certification is key. These certifications require testing on the final printed product, not just the raw polymer. Reputable suppliers will have these certificates and can guide you through the process of certifying your final 4D-printed component.

What Are the Manufacturing and Integration Pathways?

Moving from lab samples to integrated, mass-produced components requires scalable printing technologies and designs that complement existing manufacturing lines.

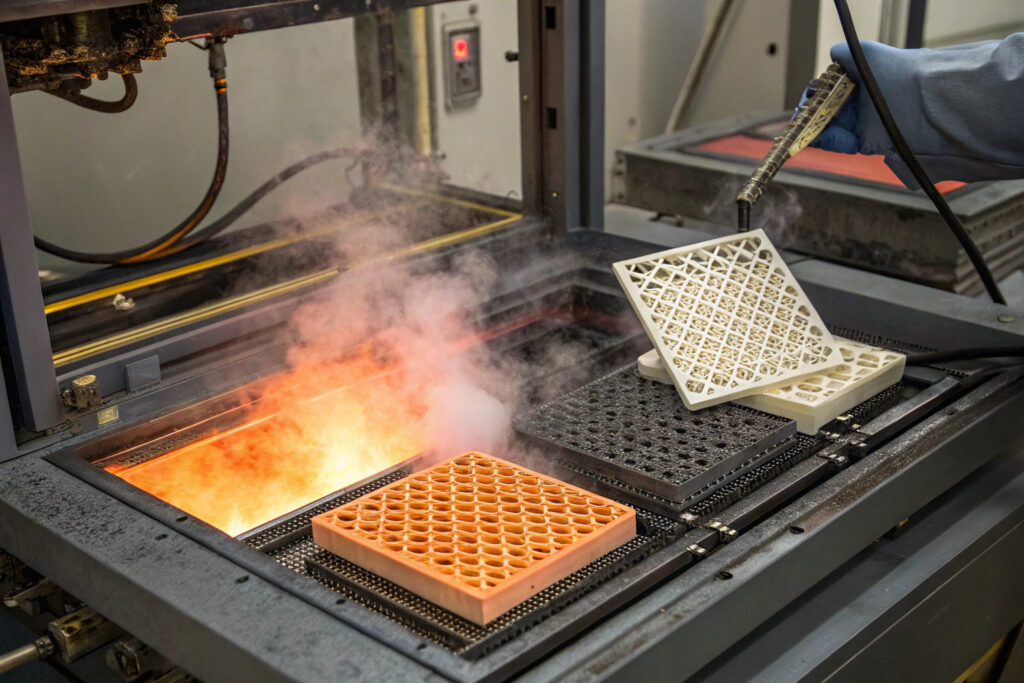

Which 4D Printing Technologies Are Scalable?

While inkjet and stereolithography (SLA) are used in research, fused deposition modeling (FDM) with smart filaments and direct ink writing (DIW) of pastes are the most scalable for wearable components. Multi-nozzle FDM systems can now print composites with spatially varying properties by switching filaments layer by layer. DIW is ideal for hydrogel-based responsive materials. The industry is moving towards roll-to-roll compatible printing of 2D preforms that later self-fold into 3D shapes (4D origami), which is highly scalable. Sourcing may involve contracting with specialized 4D printing manufacturers who have pilot-scale FDM or DIW lines capable of handling biodegradable smart materials.

How Are 4D Components Integrated into Final Products?

The most feasible strategy is hybrid manufacturing. The 4D-printed smart component (e.g., a self-adjusting seal, a responsive filter insert, or a transforming exhalation valve) is produced separately and then integrated into a conventionally manufactured mask body via biodegradable adhesives, ultrasonic welding (for thermoplastics), or mechanical snaps. This allows the high-value, complex functionality of 4D printing to be utilized where it provides the most benefit, without requiring the entire product to be printed. Design for disassembly should be considered so the 4D component can be separated for directed composting at end-of-life.

Conclusion

The latest 4D-printed biodegradable smart materials represent a pinnacle of sustainable engineering, combining programmed intelligence with environmental responsibility. For mask innovation, they enable products that adapt to the user and the environment in ways previously impossible, while guaranteeing a clean, non-toxic end-of-life. While challenges remain in scaling production and reducing costs, the trajectory is clear: the future of high-performance, sustainable wearables will be shaped by materials that are not only made from nature but are designed to intelligently interact with it and return to it.

Ready to pioneer the next generation of adaptive, sustainable masks with 4D-printed smart materials? Contact our Business Director, Elaine, at elaine@fumaoclothing.com. Our R&D team is actively exploring partnerships with leading material developers to bring these transformative technologies from the lab to functional, market-ready products.