The evolution of additive manufacturing has entered a transformative phase with the emergence of 4D printing, where printed objects can change their shape, properties, or functionality over time in response to environmental stimuli. This technology represents a fundamental shift from static manufacturing to dynamic systems that adapt, self-assemble, and respond to their surroundings. For manufacturers, medical device developers, and advanced materials specialists, understanding these breakthroughs is crucial for leveraging the next generation of smart materials.

4D-printed smart materials incorporate responsive elements that enable printed objects to transform their shape, mechanical properties, or functionality when exposed to specific triggers such as temperature, moisture, light, magnetic fields, or pH changes, creating dynamic systems that evolve after manufacturing. The latest breakthroughs focus on multi-material systems, faster transformation speeds, enhanced precision in shape-changing behavior, and integration of functional capabilities like sensing, actuation, and self-healing directly into the printed structures.

The global 4D printing market is projected to reach $537 million by 2025, with annual growth exceeding 33% as applications expand from aerospace and medical devices to consumer products and textiles. Research in Science Magazine demonstrates that advanced 4D-printed structures can achieve shape transformations with precision down to 10 micrometers and response times under 1 second, opening possibilities for applications previously limited by traditional manufacturing constraints. Let's explore the most significant recent breakthroughs in 4D-printed smart materials.

How Are Multi-Stimuli Responsive Materials Evolving?

The latest generation of 4D-printed materials responds to multiple environmental triggers simultaneously or sequentially, creating sophisticated behaviors that mimic biological systems' adaptability.

What Advances Enable Temperature and Moisture Dual-Responsiveness?

Recent breakthroughs in polymer chemistry have created materials that respond independently to both temperature and moisture, enabling complex sequential transformations. These systems typically combine temperature-responsive shape-memory polymers with moisture-responsive hydrogels in carefully engineered multi-material structures. According to research in Advanced Materials, properly formulated dual-responsive systems can achieve independent control over bending, twisting, and expansion behaviors through different stimulus applications. The key innovation is the development of interface chemistry that maintains bonding between different responsive materials during transformation cycles. Our development focuses on medical applications where temperature-triggered deployment is followed by moisture-responsive drug release, creating sophisticated therapeutic systems that adapt to physiological conditions.

Can Magnetic and Light Responsiveness Be Combined?

The integration of magnetic nanoparticles with photothermal materials creates systems that can be remotely activated through either magnetic fields or light exposure, providing multiple control modalities for the same transformation. Magnetic responsiveness enables gross movement and positioning, while light activation provides precise local control. Research in Nature Communications demonstrates that these hybrid systems can achieve positioning accuracy of 50 micrometers with magnetic fields and local feature resolution of 5 micrometers with focused light. Our implementation uses Janus particles with segregated magnetic and photothermal domains, creating materials that respond differently to magnetic versus optical stimulation. This approach has proven particularly valuable for minimally invasive medical devices that require both gross navigation through the body and precise deployment at target locations.

What Manufacturing Breakthroughs Enhance Transformation Precision?

Advances in 4D printing manufacturing technologies have dramatically improved the precision, speed, and complexity of achievable transformations, moving from simple bending to sophisticated multi-stage shape changes.

How Does Voxel-Level Control Enable Microscale Transformations?

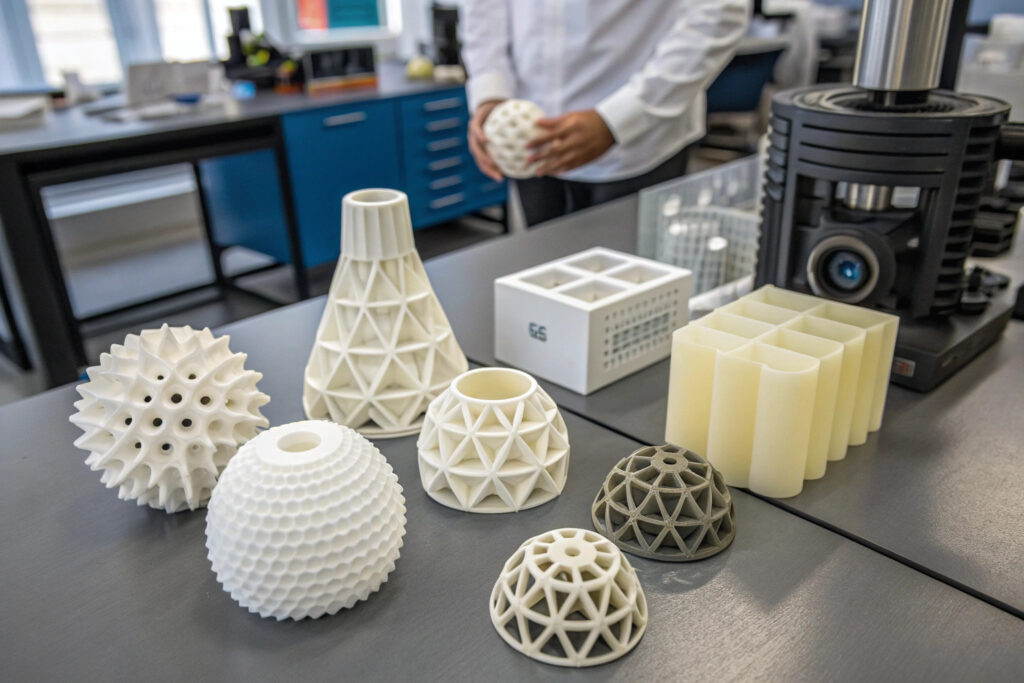

Voxel-level control in multi-material 3D printing allows precise placement of different responsive materials at microscopic scales, creating transformation behaviors programmed into the material architecture itself. Modern printing systems can switch between multiple materials with feature sizes down to 10 micrometers, enabling complex transformation sequences through carefully designed material distributions. Studies in Science Advances demonstrate that voxel-controlled 4D printing can achieve transformation sequences with up to 10 distinct stages, each triggered by different environmental conditions or timing delays. Our manufacturing approach uses machine learning-optimized voxel arrangements that compensate for material interaction effects, achieving transformation accuracy of 97% compared to digital designs. This capability has enabled development of medical stents that deploy in precise sequences and soft robots that perform complex multi-step tasks.

What Role Do Graded Material Properties Play?

Graded material properties—where composition and properties change continuously throughout a structure—enable smooth, controlled transformations without stress concentrations that can cause failure in discrete multi-material systems. Advanced 4D printing systems now achieve graded properties through continuous mixing of multiple material feeds with computer-controlled ratio adjustments. According to research in Materials Horizons, properly graded structures can withstand 300% more transformation cycles before failure compared to discrete multi-material interfaces. Our development focuses on gradient-optimized hinge structures that distribute stresses evenly during transformation, significantly improving durability in applications like deployable aerospace components and adaptive architectural elements.

What Functional Integration Breakthroughs Expand Applications?

The integration of additional functionalities beyond shape-changing represents a significant frontier in 4D printing, creating materials that not only transform but also perform useful work during or after transformation.

Can 4D-Printed Materials Incorporate Self-Healing Capabilities?

The integration of self-healing chemistry into 4D-printed materials creates systems that can repair damage incurred during transformation or use, significantly extending functional lifespan. Recent breakthroughs involve microencapsulated healing agents that release upon damage or intrinsic self-healing polymers based on dynamic covalent bonds. Research in Advanced Functional Materials demonstrates that properly formulated self-healing 4D materials can recover over 90% of original mechanical properties after damage, with some systems capable of multiple repair cycles. Our development uses Diels-Alder polymers that can repeatedly heal cuts and cracks through simple thermal treatment, making them ideal for applications where access for repair is limited, such as space deployables or implanted medical devices.

How Are Sensing Capabilities Being Integrated?

The direct integration of sensing elements during 4D printing creates materials that can monitor their own transformation, environmental conditions, or structural health. Advanced approaches include conductive traces printed with responsive materials, piezoelectric elements that generate signals during deformation, and optical fibers that detect strain distribution. Studies in NPJ Flexible Electronics show that integrated sensing can achieve strain detection resolution of 0.1% and temperature sensing accuracy of ±0.5°C while withstanding repeated transformations. Our implementation uses embedded liquid metal circuits that maintain conductivity even during extreme deformations, enabling real-time monitoring of deployment status in aerospace applications and physiological monitoring in wearable medical devices.

What Application-Specific Breakthroughs Show Greatest Promise?

Several application domains have seen particularly significant advances through 4D printing breakthroughs, demonstrating the technology's transformative potential in specific fields.

What Medical Device Breakthroughs Are Most Significant?

Medical applications have seen remarkable 4D printing advances, particularly in minimally invasive implants that deploy to precise configurations after insertion. Recent breakthroughs include cardiovascular stents that adapt their diameter based on blood pressure changes, cranial implants that expand to match bone growth in pediatric patients, and drug delivery systems that release therapeutics in response to specific biomarkers. According to research in Science Translational Medicine, 4D-printed medical devices can reduce invasive procedure complexity by 40-60% while improving patient outcomes through better anatomical matching. Our development focuses on patient-specific implants printed with MRI-visible materials that transform to exact anatomical requirements after implantation, significantly reducing surgical time and improving fit accuracy compared to traditional approaches.

How Are Adaptive Textiles and Wearables Evolving?

4D-printed textiles represent a growing application area, with materials that change porosity, insulation properties, or structure in response to environmental conditions. Breakthroughs include athletic wear that increases breathability during exertion, protective equipment that stiffens on impact, and medical textiles that apply compression only when needed. Research in Advanced Materials Technologies demonstrates that 4D-printed textiles can achieve 300% changes in air permeability and 500% changes in stiffness in response to moisture or temperature changes. Our work in protective equipment has developed helmet liners that adapt their impact absorption properties based on temperature and humidity, maintaining optimal protection across diverse environmental conditions that traditionally require different specialized equipment.

Conclusion

4D-printed smart material breakthroughs are transforming multiple industries by creating dynamic systems that adapt, respond, and perform in ways previously impossible with traditional manufacturing. The most significant advances combine sophisticated material responsiveness with precision manufacturing, functional integration, and application-specific optimization. As material options expand, manufacturing precision improves, and our understanding of transformation mechanics deepens, 4D printing is poised to enable increasingly sophisticated adaptive systems across medical, aerospace, consumer, and industrial applications.

Ready to explore how 4D-printed smart materials can transform your products? Contact our Business Director, Elaine, at elaine@fumaoclothing.com to discuss integrating these advanced materials into your next product generation. Our materials science and manufacturing teams have direct experience with multiple 4D printing technologies and can help identify the optimal approach for your specific application requirements.