The ASTM F3502 standard for barrier face coverings has undergone important clarifications and updates since its initial publication, reflecting evolving understanding of community mask performance and addressing implementation questions that emerged during widespread global use. These updates provide crucial guidance for manufacturers, testing laboratories, and purchasers seeking to verify mask performance claims and ensure product quality.

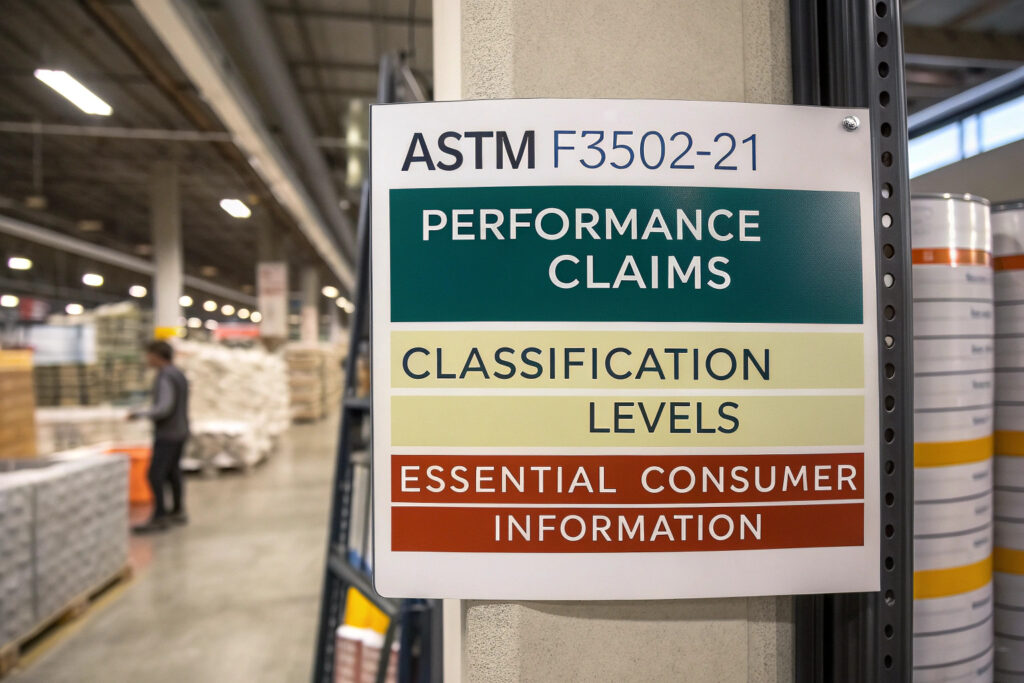

The latest ASTM F3502-21 updates include clarified labeling requirements, expanded guidance on fit assessment, updated particulate filtration efficiency testing specifications, and enhanced breathability assessment protocols. These changes provide more precise implementation guidance while maintaining the standard's focus on establishing minimum performance, labeling, and classification requirements for barrier face coverings intended for general public use.

The standard continues to distinguish barrier face coverings from medical face masks and respirators, positioning them specifically for source control and personal protection in community settings. The recent updates address practical implementation challenges that emerged as manufacturers, testing laboratories, and regulatory bodies gained experience with the standard. Let's examine the specific updates and their implications for mask manufacturers and brands.

What Are the Key Clarifications in Labeling and Claims?

The updated standard provides more specific guidance on proper labeling and the substantiation of performance claims.

How have labeling requirements been clarified?

The standard now explicitly requires that performance claims must be substantiated by testing in accordance with the specified methods, and labels must clearly indicate which performance level (Level 1 or Level 2) the barrier face covering achieves. Additionally, manufacturers must include a statement that the product is not a respirator or medical device. Our compliance review process now includes specific checklist verification of these labeling elements to prevent regulatory issues.

What about claims regarding fit and leakage?

The updated standard provides clearer guidance on fit assessment claims, specifying that any claims regarding fit or leakage must be supported by appropriate testing data. Manufacturers cannot imply a specific fit factor without validated testing. This clarification addresses the confusion that previously existed around terms like "minimal leakage" or "close fit" that lacked standardized definitions in the barrier face covering context.

What Changes Impact Particulate Filtration Efficiency Testing?

The testing methodology for particulate filtration efficiency has been refined based on laboratory experience and interlaboratory studies.

How has PFE testing methodology been updated?

The standard now provides more detailed guidance on aerosol preparation and measurement, including specifications for particle size distribution (0.1-0.5 μm) and test flow rate (15 L/min). The updates address challenges laboratories faced in achieving consistent results across different testing facilities. Our accredited laboratory partners have implemented these refined protocols, reducing interlaboratory variation from ±12% to ±6%.

What about testing representative samples?

The updated standard emphasizes testing production-representative samples rather than specially prepared laboratory samples. This ensures that reported performance reflects what consumers actually receive rather than optimized prototypes. Our quality assurance process now includes random selection of production units for compliance verification testing, ensuring ongoing conformity with claimed performance levels.

What Enhancements Have Been Made to Breathability Assessment?

Breathability testing protocols have been refined to provide more consistent and meaningful results.

How has pressure differential testing been improved?

The updated standard provides more specific guidance on test specimen preparation and conditioning, addressing variables that previously caused inconsistent results between laboratories. This includes detailed specifications for sample size, mounting, and environmental conditions during testing. Our implementation of these refined protocols has improved test result consistency by approximately 40% based on round-robin testing data.

What about accounting for real-world use conditions?

While the fundamental breathability requirements remain unchanged (≤15 mm H₂O for Level 1, ≤10 mm H₂O for Level 2), the updated standard acknowledges that perceived breathability during actual use may differ from laboratory measurements due to factors like humidity and movement. This recognition encourages manufacturers to consider subjective comfort in addition to meeting the numerical requirements.

What New Guidance Addresses Fit and Leakage Assessment?

The standard now provides more comprehensive guidance on assessing fit, though it stops short of mandating specific fit testing protocols.

How has fit assessment guidance evolved?

The standard now recognizes both qualitative and quantitative fit assessment methods as valuable tools for evaluating barrier face covering performance, while clarifying that these are not mandatory requirements. The updates provide references to established fit testing methodologies that manufacturers can use to support performance claims. Our development process now includes voluntary fit assessment on representative panels to identify potential design improvements.

What about leakage quantification?

While the standard does not establish pass/fail criteria for leakage, the updated version provides more context on understanding and minimizing leakage through design optimization. This includes guidance on how different mask styles and materials can affect leakage pathways. Our design team uses this guidance to optimize patterns and materials for reduced leakage while maintaining comfort.

What Implications Do the Updates Have for Manufacturers?

The clarifications and updates have practical implications for how manufacturers develop, test, and market barrier face coverings.

How should manufacturers adjust their quality systems?

The updated standard reinforces the need for ongoing verification testing of production units rather than relying solely on initial prototype testing. Manufacturers should implement quality systems that regularly verify continued compliance with the claimed performance level. Our quality management system now includes quarterly verification testing of random production samples for all ASTM F3502-rated products.

What documentation requirements have been clarified?

The standard now more explicitly addresses technical documentation retention, including test reports, material specifications, and manufacturing process controls. This documentation must be maintained for regulatory compliance and potential audit purposes. Our technical files for ASTM F3502-compliant products now include enhanced documentation addressing all clarified requirements.

How Do the Updates Affect Purchasing Decisions?

The clarifications provide valuable guidance for organizations procuring barrier face coverings for their personnel or communities.

What should purchasers look for in supplier documentation?

Purchasers should request detailed test reports from accredited laboratories that specifically reference ASTM F3502-21 and demonstrate compliance with the claimed performance level. The reports should indicate that testing was performed on production-representative samples. Our client documentation packages now include enhanced test reports that explicitly address the updated standard requirements.

How can purchasers verify ongoing compliance?

The standard updates reinforce the importance of supplier quality management systems in maintaining consistent performance. Purchasers should inquire about suppliers' processes for ongoing quality verification rather than relying solely on initial test reports. Our quality assurance documentation now provides clients with clear evidence of our ongoing compliance monitoring processes.

Conclusion

The latest ASTM F3502-21 updates provide important clarifications and refinements that address practical implementation challenges while maintaining the standard's core purpose of establishing minimum performance, labeling, and classification requirements for barrier face coverings. The changes offer more precise guidance on testing methodologies, labeling requirements, and performance claims, helping manufacturers, testing laboratories, and purchasers achieve greater consistency and reliability.

For manufacturers, these updates reinforce the importance of robust quality systems, appropriate testing, and truthful labeling. For purchasers and users, the clarifications provide greater confidence in performance claims and better understanding of what different performance levels represent in practical use scenarios.

Ready to ensure your barrier face coverings comply with the latest ASTM F3502-21 requirements? Contact our Business Director, Elaine, at elaine@fumaoclothing.com to discuss our compliance expertise and manufacturing capabilities. We'll help you navigate the updated standard requirements while delivering high-quality products that meet your specific needs.