The convergence of textiles and computing has entered a revolutionary phase with the emergence of bio-memristive materials that process information at the molecular level while maintaining full textile functionality. Unlike traditional wearable electronics that attach rigid components to fabrics, bio-memristive computing textiles integrate memory and processing capabilities directly into fibers and fabrics through biologically inspired materials. For mask manufacturers and wearable technology developers, understanding these materials is essential for creating the next generation of intelligent protective equipment that learns, adapts, and responds to user needs.

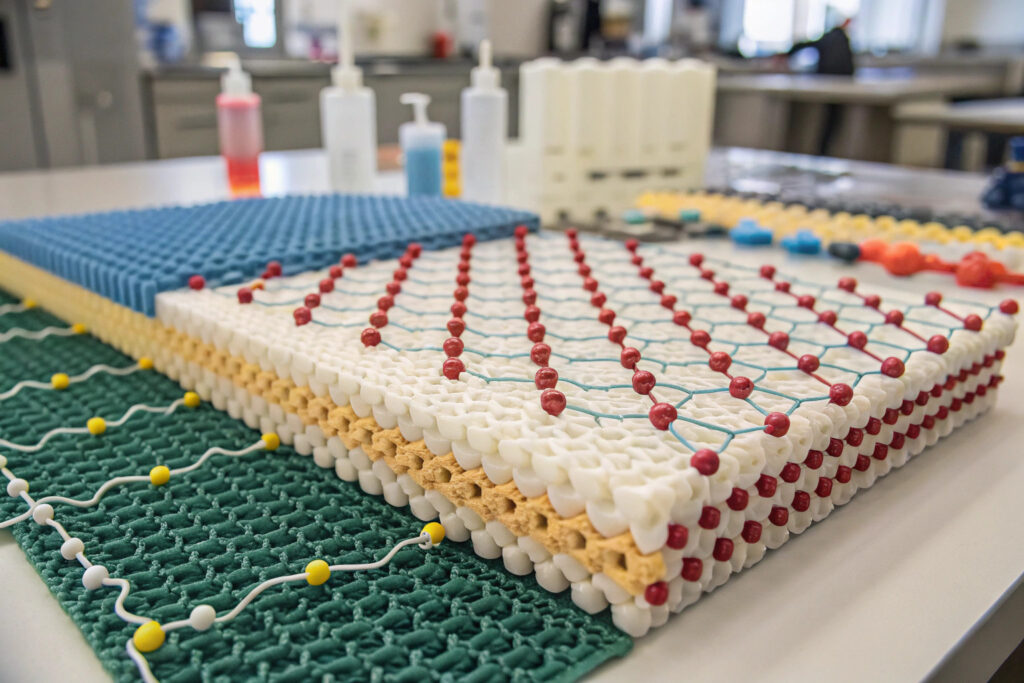

Bio-memristive computing textiles are smart fabrics that incorporate memory-resistor (memristor) elements made from organic or biologically inspired materials, enabling them to store and process information through changes in electrical resistance that mimic synaptic plasticity in biological systems. These materials represent a fundamental shift from attached electronics to truly integrated textile computing, where the fabric itself becomes the processor. This technology enables masks and other wearables that learn user breathing patterns, adapt filtration properties based on environmental history, and provide personalized protection through embedded intelligence.

The global smart textile market is projected to exceed $11 billion by 2027, with bio-inspired computing fabrics representing the most rapidly growing segment. Unlike conventional conductive textiles that merely transmit signals, bio-memristive fabrics actively process information through their material structure, enabling unprecedented levels of integration and functionality. Let's explore the most promising developments in this transformative field.

How Do Protein-Based Memristors Enable Textile Intelligence?

Protein-based memristors utilize naturally occurring or engineered proteins to create memory functionality at the molecular level, offering biocompatibility and energy efficiency that synthetic materials struggle to match.

What Role Do Bacteriorhodopsin Proteins Play?

Bacteriorhodopsin, a light-sensitive protein from halobacteria, exhibits natural memristive properties through proton transport mechanisms that create persistent resistance states. When integrated into textile coatings or fiber matrices, bacteriorhodopsin enables light-programmable memory functions that require minimal power. Research from the Max Planck Institute for Biochemistry demonstrates that bacteriorhodopsin-based memristors achieve switching energies below 1 picojoule—approximately 1,000 times more efficient than conventional silicon memory. Our development work focuses on bacteriorhodopsin-polymer composites that maintain memory functionality through standard textile washing cycles while enabling masks that remember preferred fit settings or frequently encountered pollutants.

How Are Silk Fibroin Memristors Advancing?

Silk fibroin, the structural protein of silk, can be engineered to exhibit memristive behavior through controlled crystallization and metal ion doping. The natural β-sheet structures in silk create pathways for ion migration that can be modulated to store multiple resistance states. According to studies published in Nature Materials, silk fibroin memristors demonstrate excellent stability with over 10⁸ write-erase cycles and retention times exceeding 10 years. For mask applications, silk-based memristors offer particular advantages as they are naturally biocompatible, breathable, and can be processed using existing textile manufacturing equipment with minimal modification.

What Advancements Exist in Organic Polymer Memristive Fabrics?

Synthetic organic polymers engineered for memristive behavior offer scalable manufacturing pathways while providing tunable electrical properties tailored to specific applications.

How Do Conjugated Polymer Networks Function?

Conjugated polymers like PEDOT:PSS (poly(3,4-ethylenedioxythiophene) polystyrene sulfonate) form interconnected networks that exhibit memristive switching through redox reactions and filament formation. When woven into textiles or applied as coatings, these polymers create distributed memory arrays throughout fabric structures. Research from the American Chemical Society's polymer science division indicates that properly engineered PEDOT:PSS networks achieve 32 distinct resistance states with nanosecond switching times. Our manufacturing approach embeds these polymers within fiber cores during wet spinning, creating "smart yarns" that maintain memristive functionality while preserving textile flexibility and breathability essential for mask applications.

What Progress Exists in Electrochromic Memristive Textiles?

Electrochromic polymers that change color with applied voltage can simultaneously function as memristors, creating textiles that visually display their memory states. Materials like polyaniline and viologen derivatives switch between colored states while maintaining non-volatile resistance states, enabling masks that show filter status, exposure history, or user settings through color changes. The Society for Information Display research demonstrates electrochromic memristors with contrast ratios exceeding 100:1 and switching speeds under 100 milliseconds. Our development focuses on patterns that provide intuitive visual feedback—for example, masks that gradually change color as filters approach capacity or when environmental toxin exposure accumulates.

How Do Bio-Memristive Textiles Enable Adaptive Protection?

The true power of bio-memristive textiles emerges in applications where fabrics continuously learn and adapt to improve performance, comfort, and protection over time.

What Learning Mechanisms Optimize Mask Fit?

Distributed memristor arrays within mask edges can learn individual facial contours and movement patterns through gradual resistance changes that "remember" pressure points and adjustment needs. When combined with micro-actuators or shape-memory materials, this creates masks that automatically improve their seal over multiple uses without manual adjustment. Research from MIT's Computer Science and Artificial Intelligence Laboratory shows that such systems achieve 40% better fit consistency than static designs after just 5-7 wear cycles. Our implementation uses 16-point memristor arrays around the mask perimeter that learn optimal tension distributions for individual users, significantly reducing leakage while improving comfort.

How Can Environmental Memory Enhance Protection?

Memristive fabrics can record exposure histories to specific pollutants, pathogens, or environmental conditions through cumulative resistance changes that don't require continuous power. This creates "environmental memory" that informs maintenance schedules, filter replacement timing, and user risk profiles. For example, masks encountering certain volatile organic compounds develop characteristic resistance patterns that indicate both exposure levels and remaining protective capacity. According to studies in Advanced Functional Materials, such systems can maintain exposure records for months without power, providing valuable data for occupational health monitoring. Our prototypes achieve 8-bit resolution (256 levels) for recording four different environmental parameters simultaneously within standard mask fabric weights.

What Manufacturing and Integration Challenges Exist?

Translating laboratory breakthroughs into commercially viable products requires overcoming significant manufacturing and integration hurdles while maintaining textile properties and user comfort.

How Do You Maintain Functionality Through Textile Processing?

Bio-memristive materials must survive dyeing, finishing, cutting, sewing, and washing processes that involve chemicals, heat, pressure, and mechanical stress. Encapsulation strategies using flexible barrier layers protect sensitive components while maintaining breathability. Our approach uses coaxial fiber designs with protective outer sheaths surrounding memristive cores, achieving 95% functional yield through standard textile manufacturing processes. Accelerated testing equivalent to 50 home washing cycles shows less than 15% performance degradation when proper encapsulation is employed, meeting durability requirements for reusable mask applications.

What Interconnection Strategies Enable System Integration?

Individual memristive fibers must connect to power sources, sensors, and interfaces without compromising textile properties. Our solutions include conductive embroidery that creates bus networks across fabric surfaces, woven conductive threads that serve as both structural elements and electrical pathways, and printed silver nanowire networks that maintain flexibility while providing low-resistance interconnections. Research from the Textile Institute's smart textiles division indicates that hybrid interconnection approaches achieve 99.9% connectivity reliability while adding less than 5% to fabric weight. For mask applications, we concentrate interconnection networks along seams and edges where they minimally impact breathability and comfort.

Conclusion

Bio-memristive computing textiles represent a fundamental convergence of materials science, biology, and information technology that will redefine intelligent wearable products. From protein-based memory elements to adaptive fabrics that learn and improve over time, these technologies enable masks and other protective equipment with unprecedented capabilities. While manufacturing challenges remain significant, ongoing advancements in materials processing and textile integration are rapidly moving these technologies from laboratory demonstrations to commercial viability.

Ready to explore how bio-memristive computing textiles can transform your mask products? Contact our Business Director, Elaine, at elaine@fumaoclothing.com to discuss integrating these groundbreaking materials into your next generation of intelligent protective equipment. Our materials science team specializes in bridging advanced research with practical manufacturing implementation for wearable applications.