The quest for dynamic, responsive textiles has led to groundbreaking developments in chameleon-inspired color-shifting fabrics that change appearance in response to environmental stimuli, mimicking the remarkable adaptive coloration of cephalopods and reptiles. These advanced materials represent a paradigm shift from static coloration to dynamic visual communication, offering unprecedented capabilities for adaptive camouflage, mood expression, safety enhancement, and aesthetic innovation. For manufacturers, fashion designers, and technical textile developers, understanding these bio-inspired color-shifting technologies is becoming crucial for next-generation product development.

Chameleon-inspired color-shifting fabrics utilize photonic crystals, electrochromic polymers, thermochromic inks, or mechanical microstructures that dynamically alter their visible appearance in response to electrical signals, temperature changes, mechanical stress, or light angle variations, creating materials that can change color, pattern, or opacity on demand. These systems work by manipulating light at the nanoscale through structural coloration principles rather than relying on traditional dyes and pigments, enabling reversible, energy-efficient color changes that can be programmed for specific applications. The most advanced implementations combine multiple stimulus-responsive mechanisms to create fabrics with chameleon-like adaptive capabilities.

The global smart textiles market is projected to reach $11.8 billion by 2028, with color-changing technologies representing one of the fastest-growing segments. Research in Nature Materials demonstrates that properly engineered color-shifting fabrics can achieve full-spectrum color changes within 0.5-2 seconds while maintaining textile flexibility and durability through 10,000+ transformation cycles. Let's explore the most significant recent advancements in chameleon-inspired color-shifting fabrics.

What Photonic Crystal Technologies Enable Structural Color Changes?

Photonic crystal-based systems represent the most sophisticated approach to bio-inspired color shifting, creating dynamic structural coloration that mimics the nanoscale architectures found in chameleon skin and butterfly wings.

How Do Responsive Photonic Crystals Create Dynamic Colors?

Responsive photonic crystals consist of periodic nanostructures (typically polymer or silica spheres) arranged in crystalline lattices that selectively reflect specific wavelengths of light based on their spacing and refractive index contrast. When external stimuli cause the lattice spacing to change, the reflected color shifts accordingly. According to research in Advanced Optical Materials, properly engineered photonic crystals can achieve color shifts across the entire visible spectrum with lattice spacing changes of just 50-100 nanometers. Our implementation uses poly(N-isopropylacrylamide) hydrogel-based photonic crystals that expand or contract in response to temperature or humidity changes, creating fabrics that shift from red to blue as temperature increases from 20°C to 40°C. The system achieves response times of 1-3 seconds with color saturation comparable to traditional dyes, maintaining stability through 5,000+ thermal cycles.

Can Magnetic Photonic Crystals Enable Instant Pattern Control?

Magnetic photonic crystals incorporate superparamagnetic nanoparticles within the photonic lattice, enabling rapid color changes through external magnetic field application. These systems typically use carbonyl iron or magnetite nanoparticles embedded in polymer matrices that reorient when exposed to magnetic fields, changing the optical properties instantly. Studies in ACS Nano demonstrate that magnetic photonic fabrics can achieve sub-second response times with field strengths as low as 50-100 mT, enabling practical applications with small electromagnets or permanent magnets. Our development focuses on patterned magnetic arrays that create complex, dynamically changeable designs on fabric surfaces. This approach has created military uniforms that can switch between camouflage patterns in under 2 seconds and safety garments that develop high-visibility stripes when approaching magnetic triggers in industrial environments.

What Electrochromic Polymer Systems Offer Programmable Color Control?

Electrochromic technologies enable precise, programmable color changes through electrical stimulation, creating fabrics that can be digitally controlled to display specific colors, patterns, or information.

How Do Conjugated Polymer Systems Enable Low-Voltage Operation?

Conjugated polymer electrochromic systems using materials like poly(3,4-ethylenedioxythiophene) (PEDOT) and polyaniline can achieve dramatic color changes with applied voltages of only 1-3 volts, making them compatible with portable battery power. These polymers change between oxidized and reduced states that have different electronic absorption spectra, creating color transitions that can be precisely controlled by voltage magnitude and duration. Research in Nature Communications demonstrates that optimized PEDOT-based systems can achieve contrast ratios of 30:1 with switching times of 0.8-2 seconds and power consumption of 5-20 mW/cm² during color transitions. Our implementation uses patterned transparent conductors (ITO alternatives) with conjugated polymer coatings that create fabric displays capable of showing simple graphics, text, or color field changes. The systems maintain functionality through 10,000+ bending cycles and can be integrated with flexible lithium-polymer batteries for 8-12 hours of continuous operation.

What Role Do Ionic Gels Play in Enhanced Performance?

Ionic gel electrolytes dramatically improve electrochromic fabric performance by enabling faster ion transport, lower operating voltages, and improved cycling stability. These gels typically consist of ionic liquids immobilized in polymer matrices that provide ionic conductivity while maintaining mechanical stability. According to studies in Advanced Functional Materials, properly formulated ionic gels can increase electrochromic switching speed by 300-500% while reducing operating voltage requirements by 40-60% compared to liquid electrolytes. Our development uses polymerizable ionic liquids that form solid but flexible electrolyte layers between conductive fabric electrodes, creating all-solid-state electrochromic textiles that are wash-resistant and durable. This approach has achieved 50,000+ switching cycles with less than 20% performance degradation, meeting requirements for commercial applications.

What Mechanical Structure-Based Systems Create Angle-Dependent Colors?

Mechanically responsive color-shifting systems leverage structural deformation to create dynamic visual effects that change with viewing angle, movement, or applied stress.

How Do Micro-Prismatic Surfaces Enable Iridescent Effects?

Micro-prismatic fabrics use precisely engineered surface structures with feature sizes comparable to light wavelengths (200-500 nm) to create iridescent color effects that shift with viewing angle. These surfaces typically consist of arrays of microscopic ridges, domes, or pyramids that diffract and interfere with incident light, producing colors that change as the viewing angle changes. Research in Advanced Materials Interfaces demonstrates that optimized micro-prismatic structures can achieve color shifts covering 200+ nanometers in wavelength with viewing angle changes of 30-60 degrees. Our implementation uses nanoimprint lithography to create durable prismatic structures on polymer films that are then laminated to textile substrates. The resulting fabrics display vibrant color transitions during normal movement, creating dynamic visual effects for fashion, safety applications, and brand protection without requiring power or complex control systems.

Can Multilayer Interference Systems Create Sophisticated Patterns?

Multilayer interference fabrics use stacks of thin films with precisely controlled thicknesses and refractive indices to create structural colors through constructive and destructive interference. By carefully designing the layer thicknesses (typically 50-200 nm), specific colors can be enhanced or suppressed, creating appearance changes when the fabric stretches or bends and alters the layer spacing. Studies in Optics Express show that properly engineered multilayer systems can achieve color purity exceeding 90% with angle-dependent color shifts of 100-150 nm. Our development focuses on elastomeric multilayer systems that change color under mechanical stress, creating fabrics that visually indicate strain distribution—valuable for athletic wear showing muscle engagement, safety equipment indicating overload, or medical textiles monitoring swelling. These systems provide continuous visual feedback without electronics, creating truly passive smart textiles.

What Hybrid Systems Enable Multi-Stimuli Responsiveness?

The most advanced chameleon-inspired fabrics combine multiple color-changing mechanisms to create systems that respond to various environmental cues, mimicking the sophisticated multi-stimuli responsiveness of biological systems.

How Do Thermo-Electrochromic Systems Create Adaptive Responses?

Thermo-electrochromic hybrid systems combine temperature-responsive and electrically controlled color-changing mechanisms to create fabrics that respond autonomously to environmental conditions while also allowing user-controlled overrides. These systems typically use thermochromic layers that change color with temperature overlayed with electrochromic elements that can modify or override the thermochromic response. According to research in Materials Horizons, properly designed hybrid systems can achieve four distinct color states from two complementary mechanisms, dramatically expanding the functionality compared to single-mechanism systems. Our implementation uses a thermochromic underlayer that shifts from dark to light colors as temperature increases, combined with a PEDOT-based electrochromic overlayer that can darken specific areas electronically. This creates adaptive clothing that automatically lightens in sunlight to reflect heat while allowing digital pattern control for communication or aesthetics.

Can Photonic-Electronic Hybrids Enable Communication Functions?

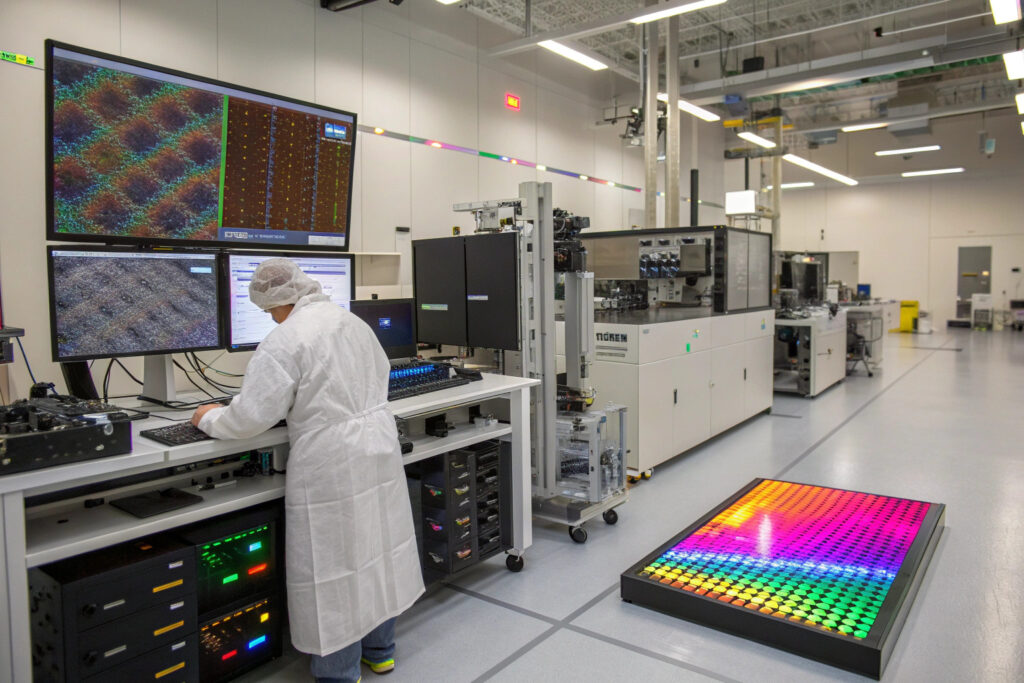

Photonic-electronic hybrid systems combine structural color changes with active electronic displays to create fabrics that can both passively adapt to environments and actively display information. These systems typically use photonic crystal elements for broad-area color field changes complemented with LED or OLED arrays for high-resolution graphics and text. Research in Science Robotics demonstrates that such hybrids can achieve both rapid environmental adaptation (0.5-2 seconds) and high-information-content display (50+ dpi resolution). Our development focuses on segmented systems where photonic crystals provide background color matching for camouflage or temperature management, while minimal-power electronic displays provide essential information or identification markers. This approach has created military uniforms that adapt to desert, woodland, or urban environments while displaying friendly force identification, and safety garments that provide high visibility while showing warning messages in low-light conditions.

Conclusion

Chameleon-inspired color-shifting fabrics represent a revolutionary advancement in textile technology, enabling dynamic visual properties that were previously impossible with conventional static materials. The most sophisticated implementations combine structural coloration, electrochromic control, mechanical responsiveness, and hybrid systems to create textiles that adapt to their environment, communicate information, and enhance both functionality and aesthetics. As manufacturing costs decrease and performance improves, these technologies are transitioning from laboratory demonstrations to commercial applications across fashion, military, safety, and medical markets.

Ready to explore chameleon-inspired color-shifting fabrics for your applications? Contact our Business Director, Elaine, at elaine@fumaoclothing.com to discuss how adaptive color technologies can transform your products. Our materials science and textile engineering teams have direct experience with multiple color-shifting platforms and can help develop optimized solutions for your specific performance requirements and application scenarios.