The Cradle-to-Cradle Certified® Product Standard has evolved significantly, offering fabric mask manufacturers increasingly sophisticated pathways to demonstrate comprehensive product sustainability. As consumers and regulators demand greater environmental accountability, these certifications have moved from niche differentiators to essential market requirements for forward-thinking brands. Understanding the latest certification options helps manufacturers implement truly circular approaches rather than incremental environmental improvements.

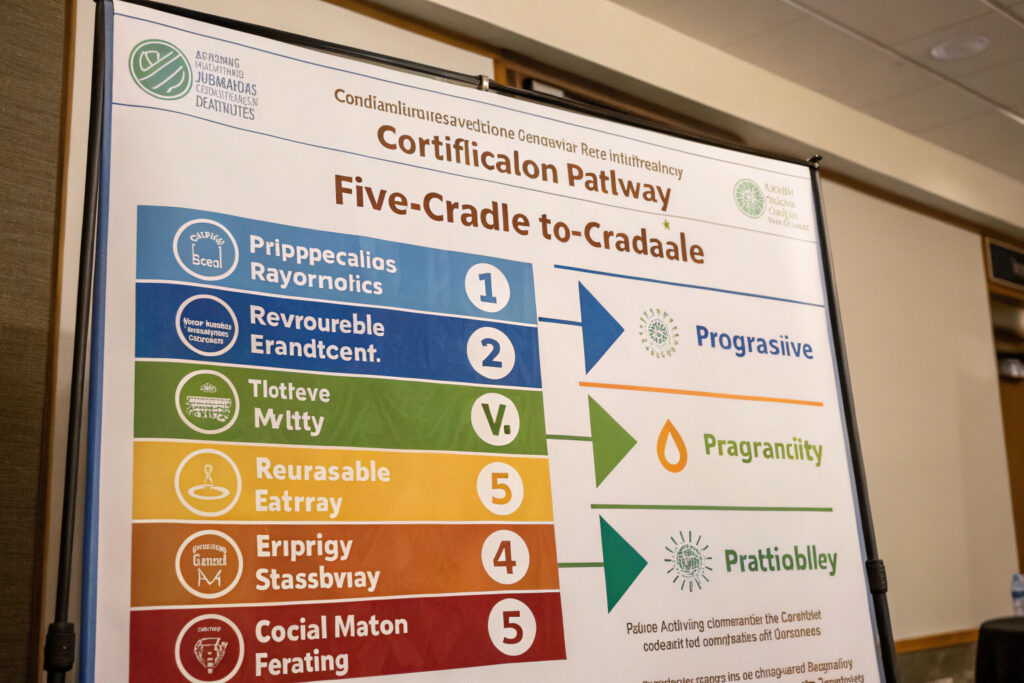

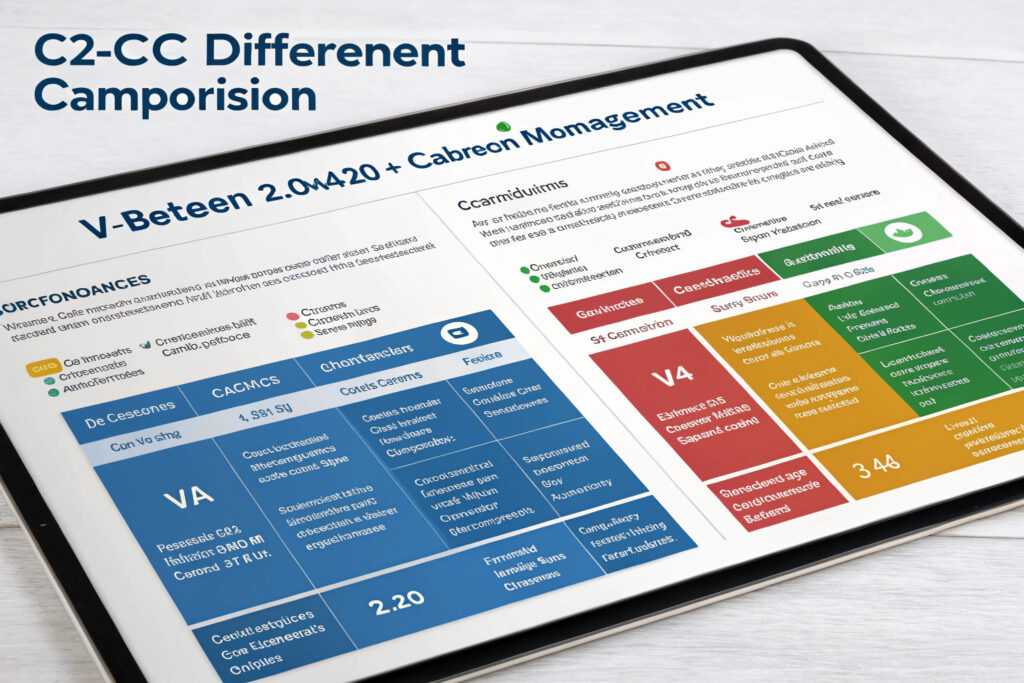

The latest Cradle-to-Cradle certification options for mask production include the updated Version 4.0 standard with its five certification levels (Basic, Bronze, Silver, Gold, Platinum), specialized Material Health Certificates for individual components, and the new Cradle-to-Cradle Certified® Product Standard with enhanced focus on carbon management and social fairness. These frameworks provide comprehensive assessment across material health, product circularity, clean air & climate protection, water & soil stewardship, and social fairness.

The Cradle-to-Cradle Products Innovation Institute has progressively raised certification standards, requiring manufacturers to address not just material selection but entire product lifecycle impacts. For mask producers, this means considering everything from raw material sourcing through end-of-life scenarios, with particular attention to material health given products' proximity to human breathing zones. Let's examine the specific certification pathways and what they require for fabric mask production.

What Are the Key Changes in Cradle-to-Cradle Version 4.0?

The latest certification version introduces more rigorous requirements that reflect evolving understanding of circular economy principles.

How do the material health requirements differ?

Version 4.0 introduces stricter material assessment protocols requiring manufacturers to disclose 100% of product ingredients above 100 ppm (parts per million), compared to the previous 1,000 ppm threshold. For mask production, this means complete transparency about dyes, finishes, antimicrobial treatments, and even processing chemicals that might remain in trace amounts. The new standard also expands the list of substances of concern, particularly targeting per- and polyfluoroalkyl substances (PFAS) commonly used in water-repellent finishes.

What about circularity and carbon management enhancements?

The updated standard requires specific circularity strategies including defined take-back programs, disassembly design principles, and verified recycled content percentages. For carbon management, manufacturers must demonstrate progressive reduction of carbon footprint and transition to renewable energy in manufacturing. Our mask designs now incorporate quick-disassembly features that allow material separation for proper recycling, a key requirement for achieving Silver level certification.

What Certification Levels Are Achievable for Fabric Masks?

Understanding the practical requirements for each certification level helps set realistic sustainability goals.

What does Bronze certification require for masks?

Bronze level represents entry-point certification requiring assessment of all materials against restricted substances lists, basic circularity strategy development, and commitment to improved environmental management. For masks, this typically means using OEKO-TEX® certified fabrics, implementing a take-back program framework, and conducting initial carbon footprint assessment. Our Bronze-certified mask line uses 95% assessed materials and has a documented plan for achieving higher certification levels.

How can masks achieve Silver or Gold certification?

Silver certification requires verified implementation of circular strategies, use of renewable energy in manufacturing, and advanced material health optimization. Gold level demands even higher percentages of preferred materials and verified social fairness practices. Our Silver-level masks incorporate 30% rapidly renewable materials (like Tencel™), are produced in facilities using 50% renewable energy, and include transparent documentation of fair labor practices throughout the supply chain.

What Are Material Health Certificate Options?

For manufacturers not ready for full product certification, Material Health Certificates provide a stepping stone.

How do Material Health Certificates work for mask components?

Component-specific certifications allow manufacturers to validate individual materials before pursuing full product certification. This is particularly valuable for masks containing multiple material types—fabrics, elastics, nose wires, and filters can each be certified separately. Our approach involves certifying each component to at least Bronze level before pursuing full product certification, reducing complexity and cost.

What is the assessment process for mask materials?

Thorough chemical inventory and assessment requires disclosing all substances down to 100 ppm concentration, evaluating them against C2C's strict criteria, and optimizing formulations to eliminate substances of concern. For mask fabrics, this often means reformulating dyes, eliminating heavy metal-based pigments, and selecting safer antimicrobial alternatives. Our material assessment process has identified and replaced 23 substances of concern across our mask material portfolio.

How Does Social Fairness Integration Work in Mask Production?

Version 4.0 places increased emphasis on social responsibility throughout the supply chain.

What social criteria must mask manufacturers meet?

Comprehensive social responsibility assessment extends beyond basic labor standards to include worker engagement, community benefit, and supply chain transparency. Manufacturers must demonstrate fair wages, safe working conditions, and meaningful stakeholder engagement. Our social fairness implementation includes worker-representative committees, living wage verification, and community education programs in our manufacturing regions.

How is supply chain transparency verified?

Multi-tier supply chain mapping requires visibility into raw material sourcing, component manufacturing, and final assembly facilities. For masks, this means tracing materials back to cotton farms or polymer producers and verifying social compliance at each stage. Our blockchain-based traceability system provides immutable records of social compliance throughout our mask supply chain.

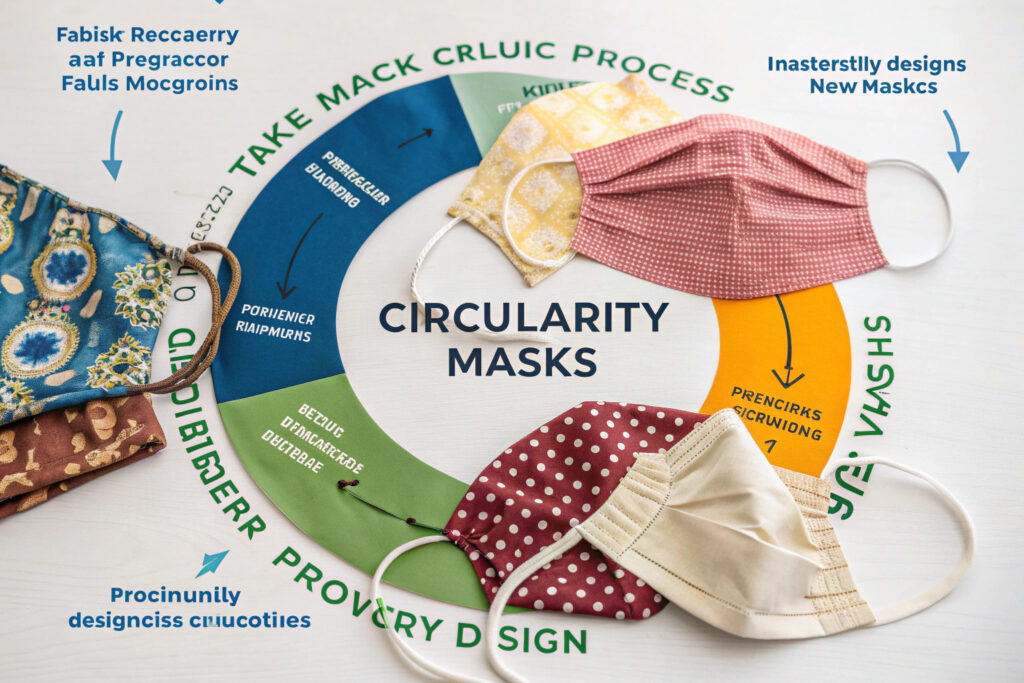

What Circularity Strategies Work for Mask Production?

Implementing effective circularity approaches is essential for higher-level certification.

How can masks be designed for circularity?

Disassembly and material separation design enables component recycling at end-of-life. This includes using mono-materials where possible, minimizing adhesive use, and designing for easy separation of different material types. Our circular mask designs use snap-in filters, mechanically attached nose wires, and color-coded material types to facilitate proper sorting and recycling.

What take-back and recycling programs are effective?

Manufacturer-managed take-back programs combined with material recovery partnerships create closed-loop systems. The most successful programs offer incentives for returns and transparently track material through recycling processes. Our take-back program has achieved 40% return rate by offering discounts on new purchases while ensuring returned masks are properly disassembled and recycled.

What Are the Implementation Challenges and Solutions?

Understanding common certification hurdles helps manufacturers develop effective implementation strategies.

How can small manufacturers manage certification costs?

Phased implementation and group certification approaches make certification accessible for smaller producers. Starting with Material Health Certificates for key components, then progressing to full product certification spreads costs over time. Our manufacturing collective enables smaller mask producers to share certification costs while maintaining individual brand identity.

What about supply chain complexity challenges?

Supplier engagement and education programs help bring supply chain partners into compliance. Rather than switching suppliers, we've developed successful partnerships that help existing suppliers meet C2C requirements through technical assistance and shared investment in improvements.

Conclusion

The latest Cradle-to-Cradle certification options for mask production offer comprehensive frameworks for demonstrating genuine product sustainability across material health, circularity, renewable energy, water stewardship, and social fairness. The updated Version 4.0 standard raises certification requirements while providing clearer pathways for manufacturers to progress from Basic to Platinum levels. For mask producers, these certifications represent not just environmental compliance but strategic market positioning as consumers increasingly prioritize verified sustainability.

The investment in Cradle-to-Cradle certification delivers returns through premium pricing, market access, brand differentiation, and future-proofing against increasingly stringent regulations. As the circular economy matures, these certifications are transitioning from competitive advantages to market expectations for responsible manufacturers.

Ready to explore Cradle-to-Cradle certification for your mask products? Contact our Business Director, Elaine, at elaine@fumaoclothing.com to discuss our certification experience and how we can help you navigate the certification process while maintaining product performance and cost efficiency. We'll provide specific guidance tailored to your current manufacturing practices and sustainability goals.